Dynamics Study of Hybrid Support Flywheel Energy

The flywheel energy storage system (FESS) of a mechanical bearing is utilized in electric vehicles, railways, power grid frequency

Get Price

World''s Largest Flywheel Energy Storage System

Beacon Power is building the world''s largest flywheel energy storage system in Stephentown, New York. The 20-megawatt system marks a

Get Price

Design and Research of a High-Temperature Superconducting

A novel energy storage flywheel system is proposed, which utilizes high-temperature superconducting (HTS) electromagnets and zero-flux coils. The electrodynamic suspension

Get Price

How about superconducting flywheel energy storage | NenPower

The primary benefits of superconducting flywheel energy storage systems include their high efficiency, durability, and energy density. These systems boast almost negligible

Get Price

REVIEW OF FLYWHEEL ENERGY STORAGE SYSTEM

Modern flywheel energy storage system (FESS) only began in the 1970''s. With the development of high tense material, magnetic bearing technology, permanent magnetic motor, power

Get Price

Development and prospect of flywheel energy storage

FESS technology originates from aerospace technology. Its working principle is based on the use of electricity as the driving force to drive the flywheel to rotate at a high

Get Price

World''s Largest Superconducting Flywheel Energy Storage

It has a large flywheel (4,000 kg with a diameter of 2 m) levitated by an innovative superconducting magnetic bearing devised by RTRI. This system is the world''s largest

Get Price

Flywheel Energy Storage System with Superconducting

In an effort to level electricity demand between day and night, we have carried out research activities on a high-temperature superconducting flywheel energy storage system (an SFES)

Get Price

Progress of superconducting bearing technologies for flywheel energy

We designed a 10 kW h class flywheel energy storage test system and investigated feasibility of active magnetic bearings for controlling rotation axis vibration under high speed

Get Price

Progress of superconducting bearing technologies for flywheel

We designed a 10 kW h class flywheel energy storage test system and investigated feasibility of active magnetic bearings for controlling rotation axis vibration under high speed

Get Price

How about superconducting flywheel energy storage

The primary benefits of superconducting flywheel energy storage systems include their high efficiency, durability, and energy density. These

Get Price

Superconducting magnetic bearing for a flywheel energy storage system

Railway power-storage facilities contribute to energy savings through energy recycling or peak shaving. Superconducting magnetic bearings support a heavy rotating

Get Price

The Amber Kinetics Energy Storage System

Amber Kinetics pioneered long duration flywheel energy storage and is now revolutionizing the field by providing high speed, rapid response and near

Get Price

Suspension-Type of Flywheel Energy Storage System Using High

In this paper, a new superconducting flywheel energy storage system is proposed, whose concept is different from other systems. The superconducting flywheel energy storage

Get Price

Design, Fabrication, and Test of a 5 kWh Flywheel Energy

Abstract The Boeing team has designed, fabricated, and is currently testing a 5 kWh / 100 kW Flywheel Energy Storage System (FESS) utilizing the Boeing patented high temperature

Get Price

Development of superconducting magnetic bearing for flywheel energy

This system has been developed in a project known as "the Technical Development for Safe, Low-Cost, Large-Capacity Battery System – the Development of the Next-Generation

Get Price

The Flywheel Energy Storage System: A Conceptual Study,

Abstract−While energy storage technologies cannot be considered sources of energy; they provide valuable contributions to enhance the stability, power quality and reliability of the

Get Price

World''s Largest Superconducting Flywheel Power Storage System

The completed system is the world''s largest-class flywheel power storage system using a superconducting magnetic bearing. It has 300-kW output capability and 100-kWh

Get Price

Conceptual Design Study of a Superconducting Flywheel System

The optimization of the field distribution as well as the HTS coil of the flywheel is discussed. Subsequently, the energy storage efficiency, power density, energy ratio and suspension force

Get Price

Development of a Superconducting Magnetic Bearing

Keywords:flywheel, energy storage system, superconducting magnetic bearing, rail applica- tion, large load 1. Introduction Flywheels are a promising storage system for high fre- quency

Get Price

Development of superconducting magnetic bearing for flywheel

This system has been developed in a project known as "the Technical Development for Safe, Low-Cost, Large-Capacity Battery System – the Development of the Next-Generation

Get Price

Overview of Control System Topology of Flywheel Energy Storage System

Abstract. Flywheel energy storage system (FESS) technologies play an important role in power quality improvement. The demand for FESS will increase as FESS can provide

Get Price

A review of flywheel energy storage rotor materials and structures

The flywheel is the main energy storage component in the flywheel energy storage system, and it can only achieve high energy storage density when rotating at high speeds.

Get Price

3D electromagnetic behaviours and discharge characteristics

1Introduction A high-temperature superconducting flywheel energy storage system (SFESS) can utilise a high-temperature superconducting bearing (HTSB) to levitate the rotor so that it can

Get Price

billyprim

What is a flywheel/kinetic energy storage system (fess)? Thanks to the unique advantages such as long life cycles, high power density, minimal environmental impact, and high power quality

Get Price

Design and Research of a High-Temperature Superconducting Flywheel

A novel energy storage flywheel system is proposed, which utilizes high-temperature superconducting (HTS) electromagnets and zero-flux coils. The electrodynamic suspension

Get Price

A Comprehensive Review on Flywheel Energy Storage

ABSTRACTFinding efficient and satisfactory energy storage systems (ESSs) is one of the main concerns in the industry. Flywheel energy storage system (FESS) is one of the most

Get Price

More related information

-

Superconducting energy storage flywheel

Superconducting energy storage flywheel

-

The first flywheel energy storage

The first flywheel energy storage

-

Mechanical battery flywheel energy storage

Mechanical battery flywheel energy storage

-

Egypt 5G flywheel energy storage construction project

Egypt 5G flywheel energy storage construction project

-

Bangladesh flywheel energy storage construction costs

Bangladesh flywheel energy storage construction costs

-

UK Flywheel Energy Storage

UK Flywheel Energy Storage

-

Iran s environmentally friendly mobile energy storage power supply

Iran s environmentally friendly mobile energy storage power supply

-

Ukrainian flywheel energy storage hybrid power source

Ukrainian flywheel energy storage hybrid power source

Commercial & Industrial Solar Storage Market Growth

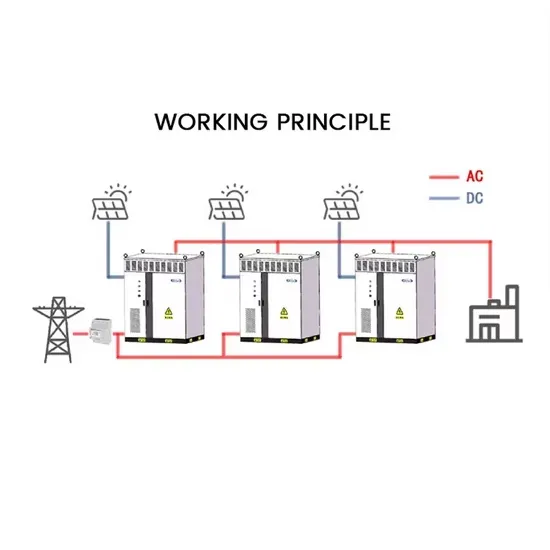

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.