Monocrystalline vs. Polycrystalline vs. Thin-Film: Which Solar

Which Solar Panel Type Should You Choose? For maximum efficiency and long-term savings → Choose monocrystalline panels, ideal for homes and businesses needing high

Get Price

What are the materials of solar polysilicon? | NenPower

The capability of solar polysilicon to conduct electricity allows for the generation of significant power when exposed to sunlight, making it a leading material of choice for

Get Price

What you need to know about polysilicon and its role in solar

What is polysilicon, what is its role in solar panels and are there any social and governance concerns around its production? Here is a primer. Polysilicon, a high-purity form of silicon, is a

Get Price

How much polysilicon is used in solar panels

In the context of solar panels, polysilicon serves as the foundational material for the creation of the cells that absorb sunlight. The quality of polysilicon can

Get Price

Properties of polycrystalline silicon cell

Polycrystalline panels – Made from polycrystalline silicon, which is more cost-effective but slightly less efficient. The choice between monocrystalline and polycrystalline

Get Price

Monocrystalline vs Polycrystalline Solar Cells and How to Choose

Monocrystalline and polycrystalline silicon solar panels With the rapid development of solar photovoltaic energy storage, its solar panel technology update iteration is also very

Get Price

Powering the Future: Inside the Solar PV Cell Manufacturing

Discover the remarkable journey of solar energy as we delve into the intricate process of photovoltaic (PV) cell manufacturing. From raw materials to finished modules, this

Get Price

The Role of Polysilicon in the Solar PV Industry A

Polysilicon — a purified version of silicon — is the main input to produce solar-grade polysilicon wafers (the building blocks of PV cells). These

Get Price

What is polysilicon and how is it made? — RatedPower

Because of this, polysilicon is crucial to the solar industry as it plays a key part when manufacturing solar cells that are used in solar panels.

Get Price

Advantages Of Polysilicon Solar Cells

Silica gel has good sealing performance, simple and convenient process, very low cost, green and environmental protection, and is very suitable for solar cells.

Get Price

Polysilicon Uses: Semiconductor & Solar | Bernreuter

With the rapid growth of the solar industry, however, that has changed. Fast forward twenty years: In 2014 the ratio between the two main

Get Price

Polysilicon Uses: Semiconductor & Solar | Bernreuter Research

With the rapid growth of the solar industry, however, that has changed. Fast forward twenty years: In 2014 the ratio between the two main uses of polysilicon had

Get Price

2X The Power | Super-Charged Solar Generator

Super-Charged Solar Bundle: Buy Patriot Power Generator & Get Our Mini Generator Free. Be Prepared For A Power Outage w/ Solar Generators, Food & Water. 100% Satisfaction.

Get Price

BLLNDX Solar Panel 0.65W 1.5V Mini Solar System DIY for

Compatible with Multiple Products 5V 6W mini solar charger can be used for home lighting and various low-power electrical appliances, small solar power generation systems, etc., comes

Get Price

Polysilicon – Knowledge and References – Taylor & Francis

Published in Anco S. Blazev, Power Generation and the Environment, 2021 Anco S. Blazev Polysilicon is a key material that is needed to manufacture c-Si solar cells, and although it is

Get Price

How much polysilicon is used in solar panels

In the context of solar panels, polysilicon serves as the foundational material for the creation of the cells that absorb sunlight. The quality of polysilicon can directly influence the efficiency and

Get Price

What are the materials of solar polysilicon? | NenPower

The capability of solar polysilicon to conduct electricity allows for the generation of significant power when exposed to sunlight, making it a

Get Price

Shedding Light on Polysilicon: Understanding Its Importance in Solar

In this blog post, we shed light on what polysilicon is exactly, how it works in solar products and why it is vital for increasing solar energy production around the world.

Get Price

Solar Grade Silicon

Solar grade silicon also has a crystalline structure that allows for the efficient conversion of sunlight into electricity. In addition to its purity and crystalline structure, solar

Get Price

Photovoltaics Manufacturing, Polysilicon | Solar Power

PV manufacturing includes three distinct processes: 1. Manufacturing silicon (polysilicon or solar-grade), 2. wafers (mono- or polycrystalline) and 3. cells and modules (crystalline and thin-film).

Get Price

Cogeneration and hydrogen production for solar-grade polysilicon

Fluor''s Louie M De los Santos explains the benefits of integrating combined heat and power (CHP) and hydrogen generation with large-scale polysilicon manufacturing,

Get Price

A Polysilicon Learning Curve and the Material

Herein, the current and future projected polysilicon demand for the photovoltaic (PV) industry toward broad electrification scenarios with 63.4 TW

Get Price

Ultrapure Silicon for Solar Power

From 2022, it will break records year after year as storage technology makes huge advances and the costs for solar electricity fall faster than any other kind

Get Price

Which is better, solar panels or polysilicon? | NenPower

In evaluating the merits of solar panels against polysilicon alternatives, numerous considerations emerge, demonstrating the complexity of the choice for potential adopters.

Get Price

The Role of Polysilicon in the Solar PV Industry A Deep Dive

Polysilicon — a purified version of silicon — is the main input to produce solar-grade polysilicon wafers (the building blocks of PV cells). These wafers utilize the photovoltaic

Get Price

What does the future hold for the price of polysilicon?

This process is referred to as the photovoltaic effect, and this is what forms the basis for solar power generation. Preparing polysilicon for use

Get Price

What is a thin film polycrystalline silicon solar cell?

When the company developed its next-generation thin-film silicon solar cells, the company focused on thin-film polysilicon and amorphous silicon tandem solar

Get Price

Which is better, solar panels or polysilicon? | NenPower

In evaluating the merits of solar panels against polysilicon alternatives, numerous considerations emerge, demonstrating the complexity

Get Price

What role does polysilicon play in the future of solar energy

Polysilicon-based solar panels have achieved conversion efficiencies ranging from 15% to 20%, which, while seemingly modest, represent a major milestone in harnessing solar

Get Price

6 FAQs about [Is polysilicon good for home use in solar power generation ]

Can polysilicon be used for solar energy generation?

These wafers utilize the photovoltaic effect to turn sunlight into electricity, meaning that polysilicon is useful for solar energy generation. It starts with the refinement of metallurgical-grade silicon into high-purity polysilicon for solar applications. The pure silicon is then cast into ingots, which are sliced into thin wafers.

Why is polysilicon important in solar PV?

As part of this global transition to renewable power, energy from solar is leading the charge and polysilicon in the solar PV is critical to facilitate this transition to renewable energy. Polysilicon, the most relevant raw material in the production of photovoltaic (PV) cells, is critical for producing solar panels that are reliable and efficient.

What percentage of polysilicon is used to make solar cells?

In 1995 its share in polysilicon demand was 90%; the remaining 10% went as scrap silicon from the semiconductor sector to the small photovoltaic (PV) branch to produce solar cells. With the rapid growth of the solar industry, however, that has changed.

What is polysilicon used for?

Polysilicon: The Heart of PV Innovation Polysilicon — a purified version of silicon — is the main input to produce solar-grade polysilicon wafers (the building blocks of PV cells). These wafers utilize the photovoltaic effect to turn sunlight into electricity, meaning that polysilicon is useful for solar energy generation.

How does the price of polysilicon affect the cost of solar panels?

Fluctuations in cost: The price of polysilicon is impacted by market demand and production costs, which impacts the affordability of solar panels. However, addressing these challenges is essential in providing a stable and sustainable supply of solar energy. Conclusion

Why is polysilicon used as a feedstock for solar PV cells?

Owing to its excellent semiconductor properties, polysilicon is used as feedstock for solar, and is the initial building block for manufacturing silicon based Solar PV cells. Due to its semiconductor properties, polysilicon is used as feedstock for solar, and is the initial building block for manufacturing silicon based Solar PV cells.

More related information

-

Is East Asian Solar Power Generation Good for Home Use

Is East Asian Solar Power Generation Good for Home Use

-

Home solar power generation system for home indoor use

Home solar power generation system for home indoor use

-

Canadian professional solar power generation for home use

Canadian professional solar power generation for home use

-

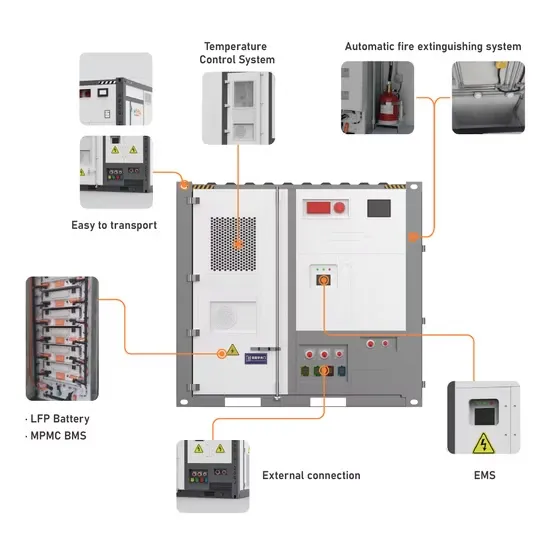

German container solar power generation for home use

German container solar power generation for home use

-

Brunei 24V solar power generation for home use

Brunei 24V solar power generation for home use

-

Arab solar power generation for home use

Arab solar power generation for home use

-

High temperature solar power generation for home use

High temperature solar power generation for home use

-

Huijue solar power generation for home use in Bolivia

Huijue solar power generation for home use in Bolivia

Commercial & Industrial Solar Storage Market Growth

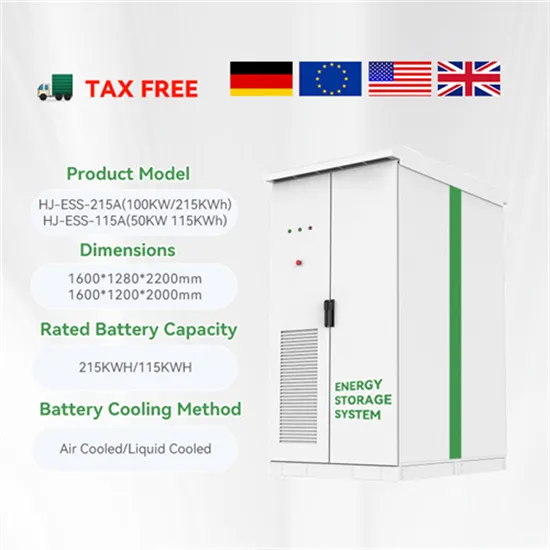

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.