Flywheel Energy Storage Systems and their Applications: A

However, the high cost of purchase and maintenance of solar batteries has been a major hindrance. Flywheel energy storage systems are suitable and economical when frequent

Get Price

How much does a flywheel energy storage system cost?

How much does a flywheel energy storage system cost? 1. The cost of a flywheel energy storage system varies based on several factors, including size, design, and installation

Get Price

Flywheel energy storage system price per KW

The total cost can be broken down into the following categories: (1) ESS cost, which is actually the overnight capital cost of the storage unit and can be divided into two parts, namely cost per

Get Price

Microsoft Word

Although lower life cycle costs, environmental advantages, and enhanced efficiency are substantial benefits offered by energy storage flywheel based UPS systems, it is clear that in

Get Price

Flywheel Energy Storage Cost per kWh: Efficiency Meets

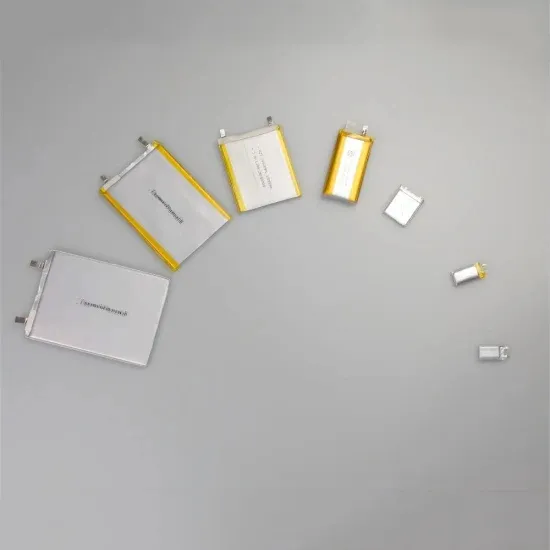

How does flywheel cost compare to lithium-ion batteries? While lithium-ion has lower upfront costs ($600-$800/kWh), flywheels achieve better lifetime value through 100,000+ charge cycles and

Get Price

Cost-Benefit Analysis of Flywheel Energy Storage in context of

While the upfront costs may be high, the long-term benefits of improved grid stability and renewable energy integration can provide a strong justification for investment.

Get Price

What is the average cost of a home battery? – Torus

Plus, the Smart Battery is part of Torus''s larger energy management platform—the Torus Station—which provides users with plenty of features and automations. Torus Flywheel: The

Get Price

HOW MUCH DOES A FLYWHEEL ENERGY STORAGE PLANT COST

How much energy does the flywheel energy storage system consume The net energy ratios of the steel rotor and composite rotor flywheel energy storage systems are 2.5–3.5 and 2.7–3.8,

Get Price

The development of a techno-economic model for the

The costs of composite and steel rotor flywheels are $190 and $146/MWh, respectively. Flywheel energy storage systems are increasingly being considered as a

Get Price

A review of flywheel energy storage systems: state of the art

This paper gives a review of the recent Energy storage Flywheel Renewable energy Battery Magnetic bearing developments in FESS technologies. Due to the highly

Get Price

Flywheel Energy Storage Basics

The high energy density and low maintenance requirements make it an attractive energy storage option for spacecraft. Conclusion: Flywheel energy storage is

Get Price

World''s Largest Flywheel Energy Storage System

Where these renewable technologies fall short is the inability to store energy without the use of gigantic battery banks. The flywheel system offers an alternative. Beacon

Get Price

Flywheel Energy Storage Costs Decoded: A 2024 Price Analysis

Unlike battery systems needing more TLC than a newborn, flywheel O&M costs average $8/kW-year versus $25+ for lithium-ion. That''s like comparing a Honda''s maintenance

Get Price

Flywheel Energy Storage Systems (FESS)

Flywheel energy storage systems (FESS) use electric energy input which is stored in the form of kinetic energy. Kinetic energy can be described as "energy of motion," in this case the motion

Get Price

Flywheel Energy Storage Systems and Their Applications: A Review

This study gives a critical review of flywheel energy storage systems and their feasibility in various applications. Flywheel energy storage systems have gained increased

Get Price

What''s the Price Tag on Flywheel Energy Storage Products?

Ever wondered how industries keep the lights on during power hiccups? Enter flywheel energy storage – the unsung hero of electricity backup systems. Unlike those sleepy

Get Price

Flywheel Energy Storage Costs: Breaking Down the Economics

Notice how per-unit costs decrease with scale - the 10 MW Jinan project achieved 18% lower per-MW pricing than smaller installations. This scaling effect mirrors what we''ve seen in solar PV

Get Price

Flywheel Energy Storage Cost per kWh: Efficiency Meets

Why Flywheel Storage is Redefining Energy Economics As global industries seek cost-effective energy storage, flywheel systems emerge as game-changers with flywheel energy storage

Get Price

Cost-Benefit Analysis of Flywheel Energy Storage in context of flywheel

While the upfront costs may be high, the long-term benefits of improved grid stability and renewable energy integration can provide a strong justification for investment.

Get Price

DOE ESHB Chapter 25: Energy Storage System Pricing

The price is the expected installed capital cost of an energy storage system. Because the capital cost of these systems will vary depending on the power (kW) and energy (kWh) rating of the

Get Price

Flywheel Energy Storage

The energy storage itself is performed using a three-phase IGBT-based PWM inverter/rectifier setup. Magnetic bearings are composed of permanent

Get Price

Energy and environmental footprints of flywheels for utility-scale

Flywheel energy storage systems are feasible for short-duration applications, which are crucial for the reliability of an electrical grid with large renewable energy penetration.

Get Price

Understanding the Cost of Flywheel Energy Storage Systems: A

These figures from Energy Storage Journal show why tech giants are spinning toward flywheels. The initial cost of flywheel energy storage systems becomes a smart

Get Price

How much does a flywheel energy storage system cost?

How much does a flywheel energy storage system cost? 1. The cost of a flywheel energy storage system varies based on several factors,

Get Price

Flywheel Energy Storage for Grid and Industrial Applications with

Flywheel Energy Storage Nova Spin included in TIME''s Best Inventions of 2024 List We''re thrilled to be one of the few selected in the Green Energy category and are excited to continue

Get Price

RotorVault Energy Storage Cost Analysis and Flywheel Price

RotorVault has a similar up-front cost, and significantly lower total cost of ownership. Compared to other technologies like supercapacitors and legacy flywheels, RotorVault has much lower

Get Price

6 FAQs about [How much does a flywheel energy storage rectifier module cost ]

Are flywheel energy storage systems economically feasible?

Equipment cost distribution for the flywheel energy storage systems. FESSs are used for short-duration power applications. Therefore, power capital cost ($/kW) could be a useful parameter to compare the economic feasibility of energy storage systems for similar power applications.

Are flywheel energy storage systems a good alternative to electro-chemical batteries?

Electro-chemical ESSs can be used in short-duration services , , but they suffer from a short lifetime and the need to dispose of toxic materials , . Flywheel energy storage systems (FESSs) are a promising alternative to electro-chemical batteries for short-duration support to the grid .

Does a flywheel storage system need a bottom-up research?

However, almost no bottom-up research has been done, i.e., research that considers the technical parameters to size the components of a flywheel storage system, estimate cost parameters based on the design, and provide a probable distribution of the total investment cost and levelized cost of storage.

What is the power rating of a flywheel energy storage system?

Utility-scale energy storage systems for stationary applications typically have power ratings of 1 MW or more . The largest flywheel energy storage is in New York, USA by Beacon Power with a power rating of 20 MW and 15 min discharge duration .

How much does a steel rotor flywheel cost?

The steel rotor flywheel has a lower capital cost and levelized cost of storage. The costs of composite and steel rotor flywheels are $190 and $146/MWh, respectively. Flywheel energy storage systems are increasingly being considered as a promising alternative to electro-chemical batteries for short-duration utility applications.

How much does a flywheel power converter cost?

The costs of a power converter for composite and steel flywheels are $49,618 and $52,595, respectively. The cost difference is due to the difference in rated power, 100 kW for the composite flywheel and 108 kW for the steel flywheel. Fig. 5. Equipment cost distribution for the flywheel energy storage systems.

More related information

-

How much does flywheel energy storage wind power cost

How much does flywheel energy storage wind power cost

-

How much does energy storage power cost in Cameroon

How much does energy storage power cost in Cameroon

-

How much does a 200kva energy storage device cost

How much does a 200kva energy storage device cost

-

How much does a Vietnamese energy storage system cost

How much does a Vietnamese energy storage system cost

-

How much does a Norwegian household energy storage battery cost

How much does a Norwegian household energy storage battery cost

-

How much does German energy storage lithium battery cost

How much does German energy storage lithium battery cost

-

How Much Does a Korean Energy Storage Battery Cost

How Much Does a Korean Energy Storage Battery Cost

-

How much does a mobile energy storage system cost in Mauritania

How much does a mobile energy storage system cost in Mauritania

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.