VRLA Battery sizing calculation for UPS

Learn how to calculate VRLA battery sizing for UPS systems to ensure reliable backup power and optimal performance in critical applications.

Get Price

Batteries and Chargers Connected in Series and Parallel | Battery

Learn how to connect batteries in series and parallel for different voltage and amp-hour capacities. Battery Tender® offers detailed instructions and diagrams for safely charging and configuring

Get Price

Calculate the number of series and parallel connections for lithium

The series and parallel connection of lithium battery packs have different goals due to different methods. Therefore, in actual use, they can be freely determined according to

Get Price

How-To Determing Solar String Size (Examples

Determine your solar string size by considering panel & inverter specs, temperature effects, and calculating maximum string size. Consult a

Get Price

White Paper

Given a number of cells in a battery pack (such as 100 cells), they can be arranged as sets of cells directly in parallel, which are then connected in series (such as a 2P50S battery), or as

Get Price

How to Understand Battery Drain: Series vs. Parallel Connections

Understanding battery drain is crucial for optimizing energy systems, particularly when deciding between series and parallel connections. This guide explores the differences,

Get Price

Galaxy VM UPS Modular Battery Cabinet wide up to 12 strings

Galaxy VM UPS Modular Battery Cabinet wide up to 12 strings Wide modular battery cabinet with up to a 12 string modular battery capacity. To be used with GVMMBTU battery string. Batteries

Get Price

Series, Parallel or Series and Parallel Battery Banks

If there are only two batteries in the series string (as in the figure 1), we would then take a cable from the open POSITIVE (+) terminal of the first battery and a cable from the open NEGATIVE

Get Price

Series / Parallel / Multi-String Battery Banks

Measuring an individual battery voltage or a whole bank of battery using any microcontroller (arduino, microship pic, Avr, Atmega, Intel, NXP, stm32)is an easy task. You

Get Price

Data Analysis to Optimize UPS Battery Performance and

In our most common UPS configuration, 30-40 battery units, each comprised of six cells are placed in series to operate the UPS during AC mains power failures. For all that follows, we

Get Price

Series / Parallel / Multi-String Battery Banks

When doing your installation, make sure the power path busbars (black lines) are equal in length and that there are no missing links on your installation, as shown on the photos below.

Get Price

Strings, Parallel Cells, and Parallel Strings

A parallel string topology almost always leads to a lower overall usable capacity and lower maximum power output. A single weak or bad cell can exponentially lower the capacity of the

Get Price

Can You Link Battery Packs? Understanding Series Vs. Parallel

In contrast, parallel configurations are better for applications needing longer run times at a stable voltage. Next, we will explore the safety considerations and best practices for

Get Price

Batteries and Chargers Connected in Series and

Learn how to connect batteries in series and parallel for different voltage and amp-hour capacities. Battery Tender® offers detailed instructions and

Get Price

How to Wire 12V Batteries in Series & Parallel (w/

Learn how to wire batteries in series, parallel, and series-parallel with our step-by-step tutorial. Increase your battery voltage and amp hour

Get Price

String Calculator » Morningstar Corporation

This String Calculator will help you decide how many Photovoltaic (PV) modules you may use in series and parallel with a Morningstar charge controller.

Get Price

Calculation of parallel string currents addendum

This post will show the theoretical calculated battery currents in parallel strings of 5, 6, 7 and 8 batteries with load currents of 100 amps times the number of batteries in the string.

Get Price

What Are The Differences Between Parallel Vs Series Batteries?

Series vs parallel battery connections determine how voltage and capacity scale. In series, voltages add (24V from two 12V batteries) while capacity (Ah) remains constant.

Get Price

Understanding Battery Pack Configurations: Series vs. Parallel

Whether you''re choosing a battery pack for an electric vehicle, a robotics project, or an energy storage system, understanding the difference between series and parallel

Get Price

Wiring Batteries in Parallel: Boost Your Power Capacity

Learn how to wire batteries in parallel to increase capacity and provide a longer-lasting power source. Find out the benefits, precautions, and step-by-step

Get Price

How to measure voltage of multiple batteries connected in string

Measuring an individual battery voltage or a whole bank of battery using any microcontroller (arduino, microship pic, Avr, Atmega, Intel, NXP, stm32)is an easy task. You

Get Price

What Happens When You Connect Batteries in Parallel?

Connecting batteries in parallel is a common practice in various applications, including power storage systems, renewable energy setups, and backup power solutions. This

Get Price

6 FAQs about [How to check the number of parallel and string power supplies in a battery cabinet]

Are batteries a and B in parallel?

Batteries A and B are in parallel. Batteries C and D are in parallel. The parallel combination A and B is in series with the parallel combination C and D. Again, the total battery pack voltage is 24 volts and that the total battery pack capacity is 40 amp-hours.

Can we measure battery voltage in parallel?

In parallel combination voltage across each battery remains same. So we can not measure individual battery voltage in this case. These are some of the ways through which batteries connected in series or parallel can be monitored. If you have any more method in your mind please let me know about it.

Should a battery pack be paralleled?

Paralleling strings together greatly increases the complexity of managing the battery pack and should be avoided unless there is a specific reason to use this configuration. In this setup, each string must essentially be treated as its own battery pack for a variety of reasons. In a below example, 2 strings of 8 cells each are placed in parallel.

How many batteries are in a series connection?

In each of the examples, the 4 batteries are identified as A, B, C, and D. Example 1, shown in Figure 4, has 2 pairs of series connected batteries joined in a single parallel connection. In this type of arrangement, we refer to each pair of series connected batteries as a "string". Batteries A and C are in series. Batteries B and D are in series.

Why are batteries connected in series?

batteries in Series. Increasing battery bank voltage.Batteries are connected in series when the goal is to increase the nominal voltage rating of one individual battery - by connecting it in series strings with at least one other individual battery of the same type and specification - to meet the operating voltage of th

Are batteries a and C in series?

Batteries A and C are in series. Batteries B and D are in series. The string A and C is in parallel with the string B and D. Notice that the total battery pack voltage is 24 volts and that the total battery pack capacity is 40 amp-hours. Example 2, shown in Figure 5, has 2 pairs of parallel-connected batteries joined in a single series connection.

More related information

-

How to use weak current backup battery cabinet with ESS power base station

How to use weak current backup battery cabinet with ESS power base station

-

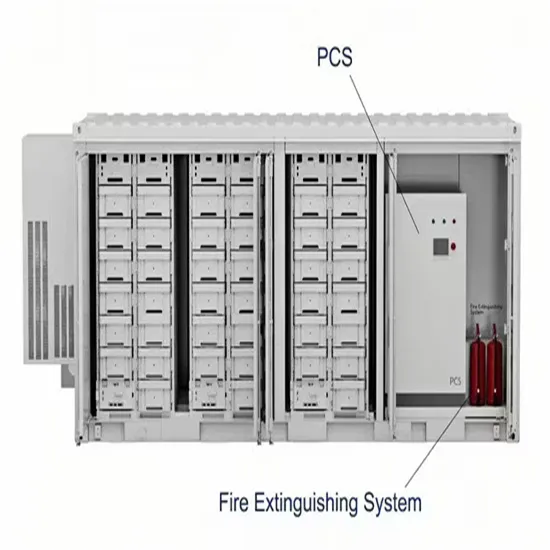

How many strings of power are usually in an energy storage battery cabinet

How many strings of power are usually in an energy storage battery cabinet

-

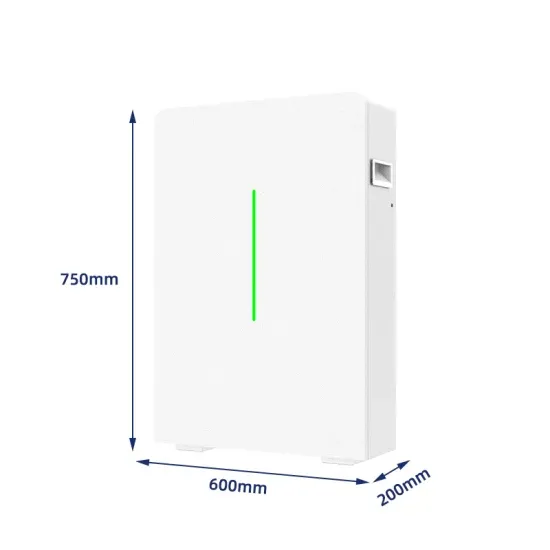

How much power does the battery cabinet output

How much power does the battery cabinet output

-

How to check the voltage of battery cabinet

How to check the voltage of battery cabinet

-

How much is the price of Andorra outdoor communication battery cabinet communication power supply

How much is the price of Andorra outdoor communication battery cabinet communication power supply

-

How to connect the signal base station battery to the power distribution cabinet

How to connect the signal base station battery to the power distribution cabinet

-

How to connect base station communication power supplies in parallel

How to connect base station communication power supplies in parallel

-

ESS power base station with battery cabinet resistance measurement

ESS power base station with battery cabinet resistance measurement

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.