UNDERSTANDING UPS SYSTEMS AND BATTERIES

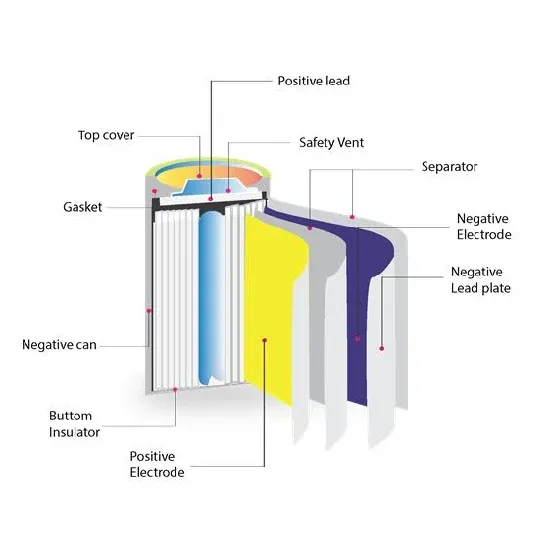

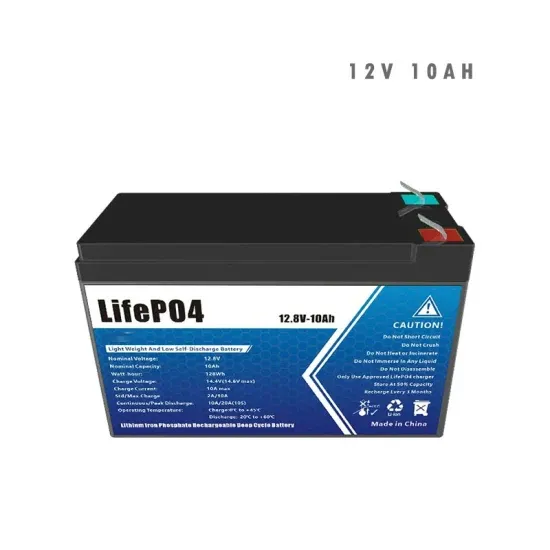

Battery types Batteries are available in a range of technologies, including lead-acid, nickel- cadmium, lithium ion, lithium-sulfur, aluminum-ion, nickel-metal, and more. Of all these, lead

Get Price

How to correctly install lithium battery energy storage cabinet?

In this guide, we will introduce the correct installation steps after receiving the lithium battery energy storage cabinet, and give the key steps and precautions for accurate

Get Price

NFPA 70 and NFPA 70E Battery-Related Codes Update

Abstract Two code documents have a dramatic impact on the acceptance or rejection of a battery installation by an inspector. These are the National Electrical Code (NEC /NFPA 70 )1 and the

Get Price

Connect the Power Cables

Connect the DC+ and DC- cables to the DC+ and DC- terminals. Connect the power cables in the UPS. If more battery cabinets are part of the solution, connect all battery cabinets to the UPS

Get Price

The Ultimate Guide to Battery Combiner Boxes:

Venturing into the realm of battery combiner boxes might seem daunting, filled with complex technical terminology. Yet, the truth of the matter is that these

Get Price

Energy Storage Battery Cabinet Installation: Your Roadmap to

Let''s face it – energy storage battery cabinets aren''t exactly the Beyoncé of renewable energy systems. But just like backup dancers, they''re critical to the show.

Get Price

Battery Cabinets & Boxes

Keep your backup energy storage systems running smoothly and safely with our durable battery boxes and cabinets. Storing and charging any type of battery in a dedicated enclosure,

Get Price

How to Install and Set Up a Battery Storage Cabinet at Home

Securing the battery storage cabinet involves using appropriate methods and materials to ensure stability and safety. Begin by selecting the correct fasteners for your wall or

Get Price

Battery Energy Storage Connectors: Types, Safety, Solutions

This guide covers types, safety standards, and installation best practices, with data-driven insights for engineers, installers, and renewable energy professionals

Get Price

Battery Cabinets

The Battery cabinet is designed to house standard VRLA Batteries of capacity range from 24Ah to 105Ah (C10). The battery cabinets are available in 5 different mechanical dimensions, are able

Get Price

BC58 Battery Cabinet Installation, Operation, & Maintenance

Battery cabinets that are not supplied with an incorporated DC output disconnect device must have an appropriate disconnect device provided external to the cabinet.

Get Price

How to correctly install lithium battery energy storage

In this guide, we will introduce the correct installation steps after receiving the lithium battery energy storage cabinet, and give the key steps

Get Price

Installation And Commissioning

The ventilation requirements for battery rooms, cabinets or compartments are based on the required reduction of the concentration of hydrogen generated during charging and safety

Get Price

Battery Room Ventilation and Safety

BATTERY ROOM VENTILATION AND SAFETY It is common knowledge that lead-acid batteries release hydrogen gas that can be potentially explosive. The battery rooms must be adequately

Get Price

Eaton Samsung Gen 3 Battery Cabinet Installation and

Control wiring can be routed through the sides of the battery cabinets in side by side configurations or through the top of the battery cabinets using conduit in standalone

Get Price

ESTEL''s Complete Guide to Telecom Battery Backup Systems

Ensure reliable telecom battery backup systems with ESTEL''s guide. Learn installation, safety, and maintenance tips to optimize performance and longevity.

Get Price

How to Connect & Charge Batteries in Series / Parallel

Series/Parallel: Battery Bank Voltage + (Battery Capacity x Battery Banks) = System Capacity and Voltage Note: that for optimal battery

Get Price

Battery Energy Storage Connectors: Types, Safety,

This guide covers types, safety standards, and installation best practices, with data-driven insights for engineers, installers, and renewable

Get Price

Battery Cabinet

For a UPS system that does not ground the DC/Battery Circuit, isolation should be maintained between the chassis and any point in the battery circuit, to reduce the risk of electric shock

Get Price

Position and Interconnect the Battery Cabinets

NOTE: This procedure describes how to position and interconnect several battery cabinets. If your system only has one battery cabinet, you only need to follow step 2 and step 3.

Get Price

Battery cabinet with extra options

Expand your Batteryguard battery cabinet with additional options | Automatic extinguishing system with cooling extinguishing foam | 400-volt power connection

Get Price

Battery Cabinet

This manual contains information on Atlantic Battery Systems battery cabinets. The information in this manual is intended for Qualified Installers, Equipment Engineers, and Field Support

Get Price

-48 VDC Battery Cabinet Installation and User Manual

Connect the power system''s battery cable terminated in an Anderson connector to the first battery cabinet''s battery cable terminated in a mating Anderson connector.

Get Price

LABNORI Lithium-Ion Battery Safety Storage Charing

1. The lithium-Ion battery charging cabinet is suitable for the storage and charging of various types of power tool batteries. The cabinet complies with the

Get Price

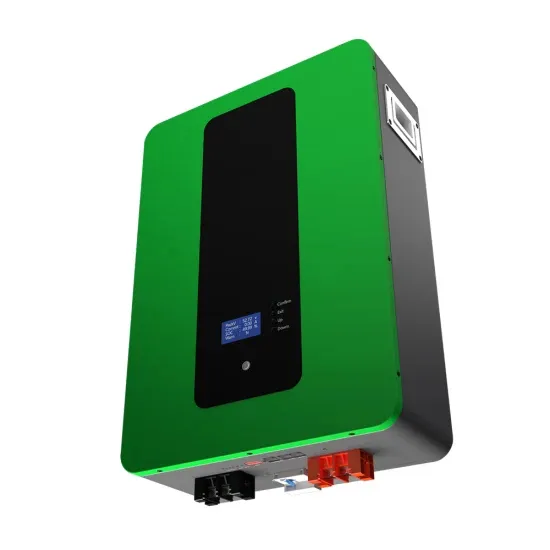

Battery Cabinet

Lithium Battery Cabinet SmartLi 3.0 Scenario where SmartLi 3.0 lithium battery cabinets are deployed outside the smart module: One integrated UPS can connect to a

Get Price

6 FAQs about [What are the connection methods of battery cabinets ]

What is a battery cabinet?

Battery cabinets are a convenient storage solution that encourages staff to maintain the correct handling and storage procedures. By charging and storing batteries in the one location, you are reducing the likelihood of batteries being lost, stolen, damaged or left in unsafe conditions (such as outdoors).

How do I connect a battery cabinet to an ups?

Connect the DC+ and DC- cables to the DC+ and DC- terminals. Connect the power cables in the UPS. If more battery cabinets are part of the solution, connect all battery cabinets to the UPS according to the diagram below.

How do you reinstall a battery cabinet?

Reinstall the left side panel on the left-most battery cabinet after interconnection. Push the third battery cabinet into position, align with the seismic anchoring (if any), level the battery cabinet, and interconnect with the other battery cabinets as described in step 2, step 3, and step 5.

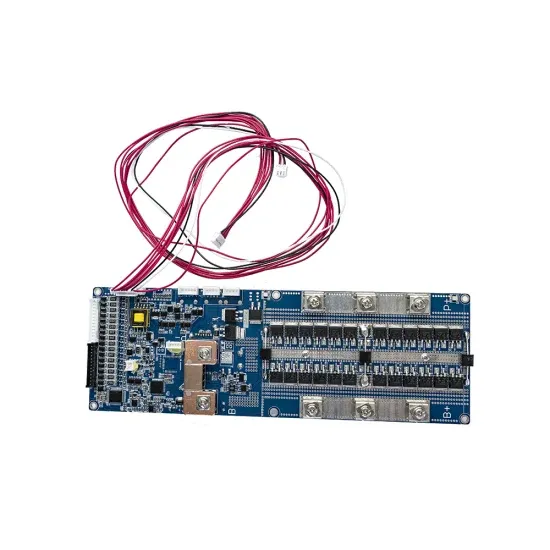

What is a battery Energy Storage Connector?

Battery Energy Storage Connectors are vital components in modern energy systems, enabling efficient power transfer between batteries, inverters, and storage units. This guide covers types, safety standards, and installation best practices, with data-driven insights for engineers, installers, and renewable energy professionals 1.

How do you level a battery cabinet?

Remove the side panels that are adjacent to the other battery cabinets. Push the right-most battery cabinet into position. For seismic anchoring, ensure that the rear seismic bracket connects to the rear anchors. Lower the levelling feet until they connect with the floor - use a bubble-leveler to ensure that the cabinet is level.

What are the different types of battery energy storage connectors?

Types of Battery Energy Storage Connectors 2.1. High-Current Busbar Connectors Design: Copper/aluminum bars for 1000A+ applications. Applications: Grid-scale lithium-ion battery racks. JAST POWER Solution: Their JBB Series Busbars achieve <0.1 mΩ resistance, ideal for megawatt-scale systems. 2.2. Plug-and-Play Blade Connectors

More related information

-

What brands of Tonga outdoor communication battery cabinets are available

What brands of Tonga outdoor communication battery cabinets are available

-

What brands are available for battery cabinets

What brands are available for battery cabinets

-

What are the technical requirements for battery cabinets

What are the technical requirements for battery cabinets

-

What brands of battery cabinets are available in Somalia

What brands of battery cabinets are available in Somalia

-

What is the utilization rate of new energy battery cabinets

What is the utilization rate of new energy battery cabinets

-

What are the manufacturers of battery replacement cabinets in Andorra

What are the manufacturers of battery replacement cabinets in Andorra

-

What battery cabinets are most common in the United Arab Emirates

What battery cabinets are most common in the United Arab Emirates

-

What brands of outdoor battery cabinets are there

What brands of outdoor battery cabinets are there

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.