Risk Assessment Report

This report summaries the high-level Safety, Health and Environmental (SHE) Risk Assessment conducted by ISHECON for the BESS installation at the proposed Sendawo SEF.

Get Price

Battery charging | Risk Management | Ecclesiastical

Batteries and associated charging equipment should be regularly inspected for defects, wear and tear. Charging equipment should be installed by a suitably qualified

Get Price

Lithium-Ion Battery Safety: Identifying Risks, Preventing Fires,

A proactive approach to lithium-ion battery safety requires comprehensive risk assessments, safe storage conditions, and robust employee training.

Get Price

Risk assessment-Battery Technologies_TJacobs_29-07

Zn-Br poses additional environmental and safety concerns relating to the use of bromine and the potential for release or exposure. Bromine creates a harsh and corrosive environment that

Get Price

Safety, Storage, Operating and Maintenance Manual VRLA

This manual contains important instructions for PowerSafeTM mSeries Lead-Acid Battery Systems that should be followed during the installation and maintenance of the battery system.

Get Price

Battery Energy Storage Systems: Main Considerations for Safe

This webpage includes information from first responder and industry guidance as well as background information on battery energy storage systems (challenges & fires), BESS

Get Price

Risk Assessment For UPS & Accessories

View Assessment - Risk Assessment For UPS & Accessories Installation.docx from ELECTRICAL ENGINEERING 313 at University of Dar

Get Price

Lithium-ion Battery Safety

Lithium-ion batteries may present several health and safety hazards during manufacturing, use, emergency response, disposal, and recycling.

Get Price

Risk assessments and the new battery standard

The new battery standard requires a thorough risk assessment process. The CEC''s James Patterson explains why this is important and

Get Price

SAMPLE RISK ASSESSMENT FOR A CLEAN ENERGY

The focus of this risk assessment is on the risk control measures necessary to minimise risks from exposure to the hazards associated with the installation, operation and maintenance of the

Get Price

White Paper Ensuring the Safety of Energy Storage Systems

Ensuring the Safety of Energy Storage Systems Thinking about meeting ESS requirements early in the design phase can prevent costly redesigns and product launch delays in the future.

Get Price

ELECTRICAL SAFETY RISK ASSESSMENT

ELECTRICAL SAFETY RISK ASSESSMENT The intent of this procedure is to perform a risk assessment, which includes a review of the electrical hazards, the associated foreseeable

Get Price

GUIDE TO INSTALLING A HOUSEHOLD BATTERY

A system where the installer makes the battery system from individual battery cells or modules on site and connects it to an inverter to make the battery storage system.

Get Price

Safety Risks and Risk Mitigation

Apart from Li-ion battery chemistry, there are several potential chemistries that can be used for stationary grid energy storage applications. A discussion on the chemistry and potential risks

Get Price

BEST PRACTICE GUIDE: BATTERY STORAGE

This guide has been developed in conjunction with a Risk Matrix - Battery Energy Storage Equipment – Risk Matrix which forms an integral part of this guide and is included as

Get Price

Battery Cabinet Risk Analysis

Can a large-scale solar battery energy storage system improve accident prevention and mitigation? This work describes an improved risk assessment approach for analyzing safety

Get Price

Download Electrical Risk Assessment for Project

Now you can download electrical Risk Assessments for Electrical Works in editable doc formats. These risk assessments are helpful for project

Get Price

Installing Battery Storage Systems Risk Assessment

Ensure to have an Emergency Management Plan in place as well as adequate numbers of trained first aid staff with easy access to fully stocked first aid kits, rescue equipment, material safety

Get Price

How do you conduct a battery safety risk assessment?

Learn how to conduct a comprehensive battery safety risk assessment through systematic hazard identification, testing procedures, and risk mitigation strategies.

Get Price

Battery Installation Safety Requirements Under ASNZS

This sample risk assessment intends to provide installers of battery systems with a guide to carrying out a risk assessment for compliance with AS/NZS 5139:2019.

Get Price

CASE STUDIES IN BATTERY RISK ASSESSMENT

Each risk assessment in this paper includes the results of shock arc flash and thermal risk assessments along with a discussion of any other specific controls to implement.

Get Price

Safety Risks and Risk Mitigation

Challenges for any large energy storage system installation, use and maintenance include training in the area of battery fire safety which includes the need to understand basic battery chemistry,

Get Price

6 FAQs about [Battery Cabinet Installation Safety Risk Assessment]

Do I need a risk assessment for a battery system?

vide installers of battery systems with a guide to carrying out a risk assessment for compliance with AS/NZS 5139. This sample is not a com te risk assessment and does not include on-site Safe Work Method Statements (SWMS) or Job Safety Analysis (JSA). Installers must carry out a risk assessment for each install

Why is AS/NZS 5139 a dangerous standard for battery energy storage?

This is because there are many types of battery energy storage technologies available and each one has specific risks associated with it. If AS/NZS 5139 stated requirements for all batteries based on those with the most extreme risks, the standard would be too strict and limit the number of batteries able to be installed.

What are the safety requirements related to batteries & Battery rooms?

Employers must consider exposure to these hazards when developing safe work practices and selecting personal protective equipment (PPE). That is where Article 320, Safety Requirements Related to Batteries and Battery Rooms comes in.

What are the different types of battery risk assessment?

Battery risk assessment can be broken up into specific hazards. We focus in this paper on electrical hazards which include electric shock, arc flash, and thermal hazards. Non-electrical hazards may include chemical (e.g., electrolyte expulsion) or battery fire / explosion, which should also be considered.

Should battery storage equipment be taken back to workshop for repairs?

isk, requires the whole equipment to be taken back to workshop for repairs. However manufacturers/importers of battery storage equipment should be aware of the risks associated with arc flash and ensure their design and

Are battery storage systems dangerous?

There has been a fair amount of news about battery storage systems being involved in fire and explosion incidents around the world. Do not forget that these are not the only safety issues when dealing with batteries. Battery systems pose unique electrical safety hazards.

More related information

-

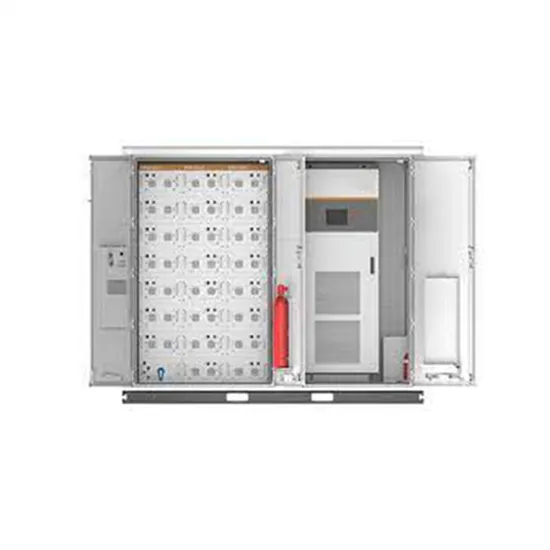

Photovoltaic communication battery cabinet battery installation

Photovoltaic communication battery cabinet battery installation

-

Lead-acid battery cabinet safety

Lead-acid battery cabinet safety

-

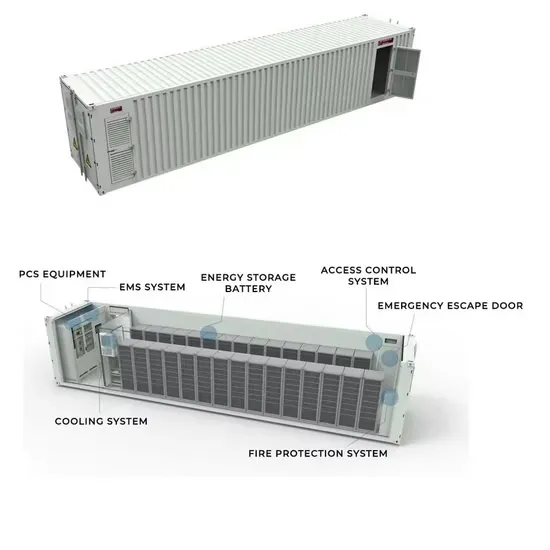

Togo Energy Storage Cabinet Battery Safety

Togo Energy Storage Cabinet Battery Safety

-

Mobilized power bank to battery cabinet installation

Mobilized power bank to battery cabinet installation

-

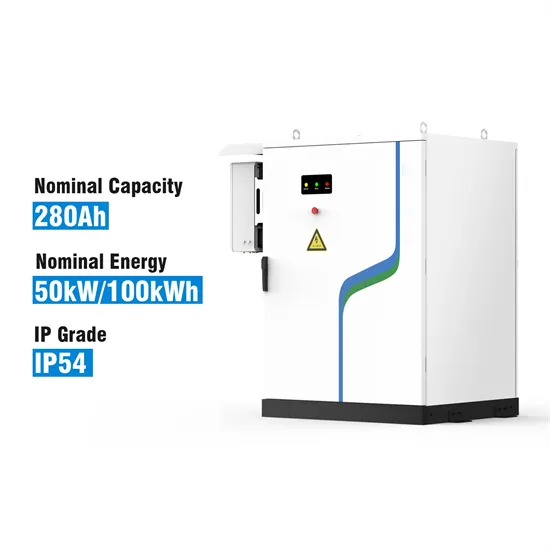

Battery cabinet installation price

Battery cabinet installation price

-

Abkhazia outdoor communication battery cabinet installation price inquiry

Abkhazia outdoor communication battery cabinet installation price inquiry

-

How many meters should the battery cabinet be separated for safety

How many meters should the battery cabinet be separated for safety

-

Battery cabinet installation heat dissipation requirements standard

Battery cabinet installation heat dissipation requirements standard

Commercial & Industrial Solar Storage Market Growth

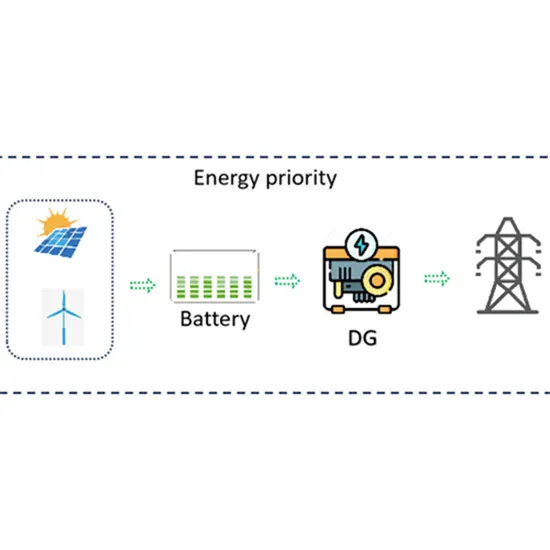

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.