CATL presents liquid-cooling CTP energy storage

CATL, a global leader of new energy innovative technologies, highlights its advanced liquid-cooling CTP energy storage solutions as it

Get Price

How to Keep Shipping Containers Cool | Expert Guide Tips

Overheating can lead to damaged goods, compromised container structure, and unsafe living or working conditions. Understanding how to keep shipping containers cool is

Get Price

Modeling and analysis of liquid-cooling thermal management of

A self-developed thermal safety management system (TSMS), which can evaluate the cooling demand and safety state of batteries in real-time, is equipped with the energy

Get Price

2.5MW/5MWh Liquid-cooling Energy Storage System Technical

The temperature control system consists of a liquid cooling unit and liquid cooling pipes. Batteries are sensitive to temperature varying, with the suitable operating temperature range for lithium

Get Price

How liquid-cooled technology unlocks the potential of

There are numerous causes of thermal runaway, including internal cell defects, faulty battery management systems, and environmental contamination. Liquid

Get Price

Interior of the liquid-cooled energy storage container

What is a liquid storage container? Liquid storage containers are those with a regulated temperature control that allows them to maintain a higher temperature to keep goods warm.

Get Price

Integrated cooling system with multiple operating modes for

The proposed energy storage container temperature control system provides new insights into energy saving and emission reduction in the field of energy storage.

Get Price

2.5MW/5MWh Liquid-cooling Energy Storage System

The 5MWh liquid-cooling energy storage system comprises cells, BMS, a 20''GP container, thermal management system, firefighting system, bus unit, power distribution unit, wiring

Get Price

Efficient Cooling System Design for 5MWh BESS Containers:

Discover the critical role of efficient cooling system design in 5MWh Battery Energy Storage System (BESS) containers. Learn how different liquid cooling unit selections impact

Get Price

How liquid-cooled technology unlocks the potential of energy storage

There are numerous causes of thermal runaway, including internal cell defects, faulty battery management systems, and environmental contamination. Liquid-cooled battery energy storage

Get Price

Understanding the Heat Inside Shipping Containers: What You

Here''s why they''re worth considering: Temperature Regulation: Climate-controlled storage boxes come equipped with heating and cooling systems, keeping the temperature

Get Price

What is the temperature range of liquid-cooled energy storage?

The temperature range for liquid-cooled energy storage systems is typically between -20°C and 60°C, with optimally functioning systems operating around 0°C to 35°C,

Get Price

customized large scale liquid cooled energy storage

Containerized Liquid-cooling Energy Storage System represents the cutting edge in battery storage technology. Featuring liquid-cooling DC battery cabinet, this

Get Price

Battery Energy Storage

Active water cooling is the best thermal management method to improve battery pack performance. It is because liquid cooling enables cells to have a more uniform temperature

Get Price

Integrated cooling system with multiple operating modes for temperature

The proposed energy storage container temperature control system provides new insights into energy saving and emission reduction in the field of energy storage.

Get Price

Liquid Cooling System Design, Calculation, and

Testing was conducted on the liquid-cooled energy storage container at an ambient temperature of 25°C. During a 0.5C charging test, the surface

Get Price

Liquid-Cooled Energy Storage, An Efficient Cooling Technology

1. Energy storage field: Liquid cooling solution becomes the mainstream trend Temperature affects the capacity, safety, life and other performance of electrochemical energy

Get Price

Liquid Cooling System Design, Calculation, and Testing for Energy

Testing was conducted on the liquid-cooled energy storage container at an ambient temperature of 25°C. During a 0.5C charging test, the surface temperature of the battery cells remained

Get Price

How Hot Do Shipping Containers Get?

Extremely Hot Temperatures Shipping Containers Can Reach and the Role of External Factors External conditions play a significant role in

Get Price

What is the temperature of the energy storage cabinet liquid cooling

The temperature of an energy storage cabinet liquid cooling cabinet typically ranges from 18°C to 25°C during optimal operation, maintaining efficiency and performance,

Get Price

What is the temperature of the energy storage cabinet liquid

The temperature of an energy storage cabinet liquid cooling cabinet typically ranges from 18°C to 25°C during optimal operation, maintaining efficiency and performance,

Get Price

CONTAINERIZED LIQUID COOLING ENERGY

Paragraph 3: Application Prospects The containerized liquid cooling energy storage system holds promising application prospects in

Get Price

Energy Storage Liquid Cooling Container Design: The Future of

Spoiler: It''s not just about keeping things chill. Energy storage liquid cooling container design is the unsung hero behind reliable renewable energy systems, electric

Get Price

Internal Temperature Management of Liquid-Cooled Energy Storage

Summary: Managing the internal temperature of liquid-cooled energy storage containers is critical during summer to ensure efficiency and safety. This article explores challenges, solutions, and

Get Price

Internal Temperature Management of Liquid-Cooled Energy

Summary: Managing the internal temperature of liquid-cooled energy storage containers is critical during summer to ensure efficiency and safety. This article explores challenges, solutions, and

Get Price

Storage Container Insulation: Essential Guide for Optimal Temperature

This means it keeps hot things hot and cold things cold by slowing down the rate at which heat moves. In the case of storage containers, this translates to maintaining a stable

Get Price

Liquid Cooling in Energy Storage: Innovative Power Solutions

This article explores the benefits and applications of liquid cooling in energy storage systems, highlighting why this technology is pivotal for the future of sustainable energy.

Get Price

Energy Storage System (ESS) Liquid Cooling Chiller

Liquid Cooling Chiller For Energy Storage Cabinet & Charging Pile >Liquid Cooling Chiller for Energy Storage Systems(ESS) Due to the thermal characteristics of batteries, thermal

Get Price

6 FAQs about [Internal temperature of liquid-cooled energy storage container in summer]

What is a composite cooling system for energy storage containers?

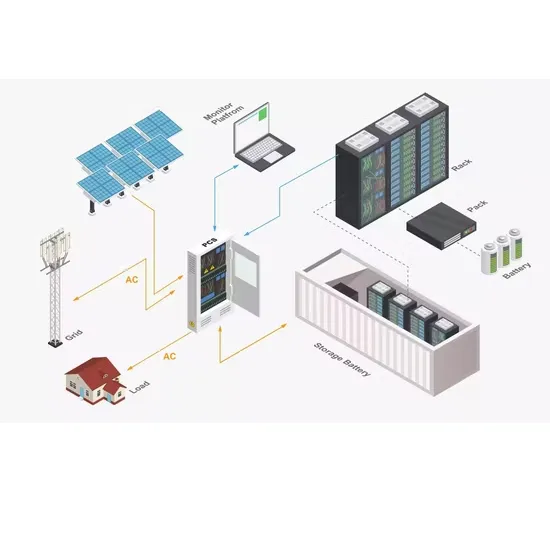

Fig. 1 (a) shows the schematic diagram of the proposed composite cooling system for energy storage containers. The liquid cooling system conveys the low temperature coolant to the cold plate of the battery through the water pump to absorb the heat of the energy storage battery during the charging/discharging process.

How much energy does a container storage temperature control system use?

The average daily energy consumption of the conventional air conditioning is 20.8 % in battery charging and discharging mode and 58.4 % in standby mode. The proposed container energy storage temperature control system has an average daily energy consumption of 30.1 % in battery charging and discharging mode and 39.8 % in standby mode. Fig. 10.

What is a container energy storage system?

Containerized energy storage systems play an important role in the transmission, distribution and utilization of energy such as thermal, wind and solar power [3, 4]. Lithium batteries are widely used in container energy storage systems because of their high energy density, long service life and large output power [5, 6].

Do cooling and heating conditions affect energy storage temperature control systems?

An energy storage temperature control system is proposed. The effect of different cooling and heating conditions on the proposed system was investigated. An experimental rig was constructed and the results were compared to a conventional temperature control system.

Are liquid cooled battery energy storage systems better than air cooled?

Liquid-cooled battery energy storage systems provide better protection against thermal runaway than air-cooled systems. “If you have a thermal runaway of a cell, you’ve got this massive heat sink for the energy be sucked away into. The liquid is an extra layer of protection,” Bradshaw says.

How much power does a containerized energy storage system use?

In Shanghai, the ACCOP of conventional air conditioning is 3.7 and the average hourly power consumption in charge/discharge mode is 16.2 kW, while the ACCOP of the proposed containerized energy storage temperature control system is 4.1 and the average hourly power consumption in charge/discharge mode is 14.6 kW.

More related information

-

Liquid-cooled energy storage container installation in Honduras

Liquid-cooled energy storage container installation in Honduras

-

What is the principle of liquid-cooled energy storage container

What is the principle of liquid-cooled energy storage container

-

Container Energy Storage Temperature Rise

Container Energy Storage Temperature Rise

-

Internal communication of energy storage container

Internal communication of energy storage container

-

Container energy storage battery temperature standard

Container energy storage battery temperature standard

-

Container Energy Storage Battery Temperature Control

Container Energy Storage Battery Temperature Control

-

Burkina Faso Energy Storage Container House Design

Burkina Faso Energy Storage Container House Design

-

Container energy storage battery replacement and debugging

Container energy storage battery replacement and debugging

Commercial & Industrial Solar Storage Market Growth

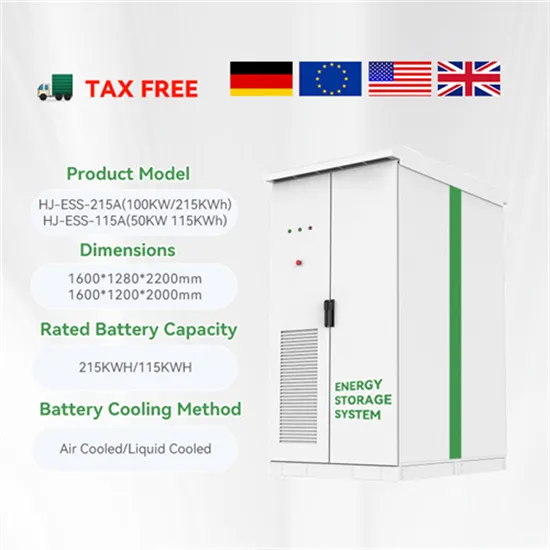

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.