UPS Battery Cabinets

UPS Battery Cabinets Unified Power offers a complete line of battery cabinets for both UPS and Telecom Applications. These cabinets can be configured to

Get Price

Battery Cabinet Solutions: Ensuring Safe Storage and Charging

Lithium-ion batteries are essential in powering tools, devices, and energy systems across industries, but they also come with inherent fire and explosion risks. To address these

Get Price

Installation and Maintenance Manual

4.2.6 External battery cabinets installation of UPS without internal batteries. For UPS with internal batteries, it can increas The external battery cabinets available are:

Get Price

The Manufacturing Process of Lithium Batteries

Welcome to our informative article on the manufacturing process of lithium batteries. In this post, we will take you through the various stages involved in

Get Price

Battery Storage Cabinets: The Backbone of Safe and

This comprehensive guide delves into the intricacies of battery storage cabinets, exploring their design, functionality, and the technological

Get Price

What Is a Battery Rack Cabinet and Why Is It Essential?

Battery rack cabinets improve energy storage efficiency by organizing batteries in a centralized, space-saving layout. They facilitate airflow to prevent overheating, extend battery

Get Price

Lithium Ion Battery Charging Cabinets

Justrite''s Lithium-Ion battery Charging Safety Cabinet is engineered to charge and store lithium batteries safely. Made with a proprietary 9-layer ChargeGuard™ system that helps minimize

Get Price

DC Chapter 11: Batteries and Power Systems –

The author has been a firsthand witness to a lead-acid battery explosion, where a spark created by the removal of a battery charger (small DC power supply)

Get Price

How Do Batteries Work? The Physics of Stored Energy

A battery is essentially an electrochemical cell, a device that converts chemical energy into electrical energy. The basic building blocks of any battery include two

Get Price

Battery Cabinets & Boxes

Why use a battery storage cabinet? Axil lockable steel cabinets and boxes provide a dedicated and controlled environment for the housing and charging of batteries and other devices. Heavy

Get Price

Uninterruptible Power Supply (UPS) Backup Battery

Arimon offers several standard monobloc or top terminal battery cabinet sizes for 10 kVA to 125 kVA UPS systems accommodating monobloc batteries from 100

Get Price

How does a cabinet battery work?

To understand how a cabinet battery works, we first need to familiarize ourselves with its key components. A typical cabinet battery consists of battery cells, a battery

Get Price

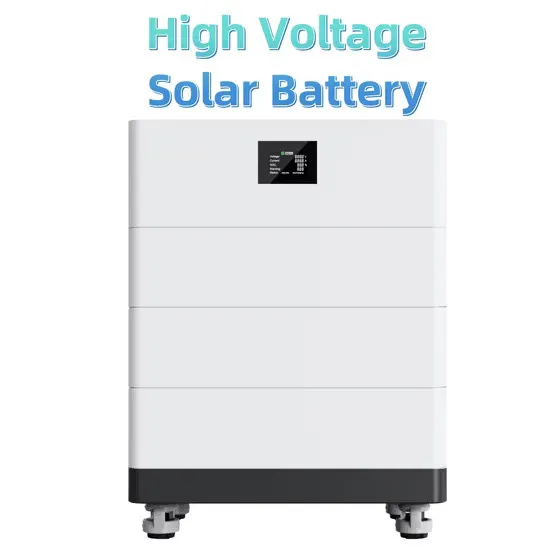

The Role of Battery Cabinet Systems in Modern Energy Storage

A battery cabinet system is an integrated assembly of batteries enclosed in a protective cabinet, designed for various applications, including peak shaving, backup power,

Get Price

How to Install and Set Up a Battery Storage Cabinet at Home

Understanding Battery Storage Cabinet Components and Benefits Key Components of a Battery Storage System A battery storage system is a sophisticated unit

Get Price

UNDERSTANDING UPS SYSTEMS AND BATTERIES

Battery types Batteries are available in a range of technologies, including lead-acid, nickel- cadmium, lithium ion, lithium-sulfur, aluminum-ion, nickel-metal, and more. Of all these, lead

Get Price

Understanding the Lithium

When a new lithium - ion battery is produced, its internal electrochemical reactions need to be stabilized. The aging cabinet achieves this by applying a precisely regulated

Get Price

Guide to Battery Cabinets for Lithium-Ion Batteries: 6

This guide explores six key factors to consider when purchasing a battery cabinet for lithium-ion batteries. Whether you''re looking for fire

Get Price

Guide to Battery Cabinets for Lithium-Ion Batteries: 6 Essential

This guide explores six key factors to consider when purchasing a battery cabinet for lithium-ion batteries. Whether you''re looking for fire protection, safe charging options, or the

Get Price

How Do Batteries Work? The Physics of Stored Energy

A battery is essentially an electrochemical cell, a device that converts chemical energy into electrical energy. The basic building blocks of

Get Price

Battery Storage Cabinet Market Size And Projection

What Are Battery Storage Cabinets? Battery storage cabinets are specialized systems used to store electricity generated from renewable energy sources. These cabinets

Get Price

The Manufacturing Process of Lithium Batteries Explained

Welcome to our informative article on the manufacturing process of lithium batteries. In this post, we will take you through the various stages involved in producing lithium-ion battery cells,

Get Price

Do Lithium Ion Batteries Require A Battery Room? Storage

Lithium-ion batteries need a battery room if their capacity exceeds 20 kWh, according to fire codes. NFPA 855 outlines ventilation and safety requirements.

Get Price

Battery Storage Cabinets: The Backbone of Safe and Efficient

This comprehensive guide delves into the intricacies of battery storage cabinets, exploring their design, functionality, and the technological advancements that make them

Get Price

Lithium-Ion Battery Charging Cabinet | 8 Outlet

De-Riskifying Battery Charging Our Australian-made, advanced battery charging cabinet provides a safe, cool, and dry environment to store and charge

Get Price

What does the energy storage cabinet consist of? | NenPower

An energy storage cabinet''s battery systems are indeed the heart of this technology. Various types of batteries can be employed, each with distinguishable

Get Price

battery cabinet,battery storage cabinet,battery bank

EverExceed designs customized battery cabinets / racks for individual batteries. The cabinet or racking system can be specified to accomodate any battery

Get Price

What Are Battery Rack Cabinets and Why Are They Essential?

Battery rack cabinets provide designated slots or shelves for batteries, simplifying inventory management and reducing installation time. Front-access designs improve

Get Price

What does the energy storage cabinet consist of?

An energy storage cabinet''s battery systems are indeed the heart of this technology. Various types of batteries can be employed, each with

Get Price

6 FAQs about [How are the batteries produced by the battery cabinet ]

How are batteries designed?

Batteries are designed to prevent abnormal temperature rise conditions and to limit current to safe levels during charge and discharge. Within the temperature, voltage, and current limits specified by the cell manufacturer, they can carry the maximum anticipated current.

How does a battery work?

Inside a battery, this energy is stored in the chemical bonds of the materials in its electrodes. The trick is to design a system where these materials can undergo reactions that release this energy in a controlled way—specifically, through the movement of electrons from one place to another. And therein lies the genius of the battery.

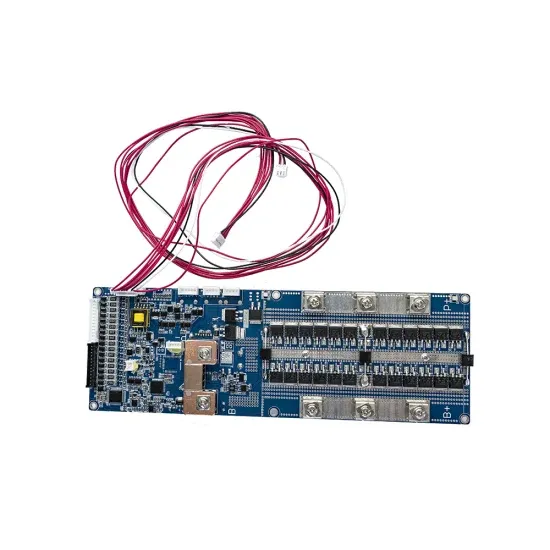

How are lithium ion batteries made?

The production of lithium-ion battery cells primarily involves three main stages: electrode manufacturing, cell assembly, and cell finishing. Each stage comprises specific sub-processes to ensure the quality and functionality of the final product. The first stage, electrode manufacturing, is crucial in determining the performance of the battery.

What is lithium battery manufacturing?

Lithium battery manufacturing encompasses a wide range of processes that result in the production of efficient and reliable energy storage solutions. The demand for lithium batteries has surged in recent years due to their increasing application in electric vehicles, renewable energy storage systems, and portable electronic devices.

What makes a battery unique?

Batteries are unique because they store energy chemically, not mechanically or thermally. This stored chemical energy is potential energy—energy waiting to be unleashed. Inside a battery, this energy is stored in the chemical bonds of the materials in its electrodes.

What is the first step in the lithium battery manufacturing process?

Electrode manufacturing is the first step in the lithium battery manufacturing process. It involves mixing electrode materials, coating the slurry onto current collectors, drying the coated foils, calendaring the electrodes, and further drying and cutting the electrodes. What is cell assembly in the lithium battery manufacturing process?

More related information

-

How are the products produced by energy storage cabinet batteries

How are the products produced by energy storage cabinet batteries

-

How to connect 16 batteries in a battery cabinet

How to connect 16 batteries in a battery cabinet

-

Where are the batteries for the energy storage cabinet produced

Where are the batteries for the energy storage cabinet produced

-

How to discharge new energy battery cabinet

How to discharge new energy battery cabinet

-

What are the products produced by energy storage cabinet batteries

What are the products produced by energy storage cabinet batteries

-

How big a base station should I buy a battery cabinet for

How big a base station should I buy a battery cabinet for

-

How much does the battery station cabinet cost

How much does the battery station cabinet cost

-

How much does an outdoor communication battery cabinet cost in Barbados

How much does an outdoor communication battery cabinet cost in Barbados

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.