DOE ESHB Chapter 7 Flywheels

A standalone flywheel developed expressly for energy storage will experience much longer charge and discharge intervals and may be operated over a speed range of greater than 2:1

Get Price

A Review of Flywheel Energy Storage System

Energy storage systems (ESS) provide a means for improving the efficiency of electrical systems when there are imbalances between supply

Get Price

A review of flywheel energy storage systems: state of the art and

A review of the recent development in flywheel energy storage technologies, both in academia and industry.

Get Price

What is the capacity of flywheel energy storage?

In summary, the capacity of flywheel energy storage is influenced by multiple core factors such as energy density, duration of energy release,

Get Price

Critical Review of Flywheel Energy Storage System

This review presents a detailed summary of the latest technologies used in flywheel energy storage systems (FESS). This paper covers the types of technologies and systems

Get Price

`FLYWHEEL POWER GENERATION AND

ABSTRACT This Case study of multi-hour electrical generation using the available rotating force from a specific weight, diameter, and rpm is considered in flywheel power generation

Get Price

General Design Method of Flywheel Rotor for Energy Storage

The maximum stress is always at the inner radius of the flywheel rotor, The maximum outer diameter decrease as inner diameter are increased. The steel flywheel or

Get Price

Technology: Flywheel Energy Storage

Large synchronous flywheels are also used for energy storage, yet not to be mistaken with FESS. They use very large flywheels with a mass in the order of 100 tonnes. These are directly

Get Price

A review of flywheel energy storage rotor materials and structures

The material characteristics of metal flywheel rotor and composite flywheel rotor are introduced. The performance characteristics of composite materials with different

Get Price

Flywheel energy storage

First-generation flywheel energy-storage systems use a large steel flywheel rotating on mechanical bearings. Newer systems use carbon-fiber composite

Get Price

Flywheel energy storage

First-generation flywheel energy-storage systems use a large steel flywheel rotating on mechanical bearings. Newer systems use carbon-fiber composite rotors that have a higher

Get Price

Flywheel Energy Storage | Working & Applications

Flywheel Contents show Flywheel Flywheel Material Components of Flywheel Flywheels Advantages Over Batteries Advantages of Flywheel

Get Price

Energy Storage Flywheel Rotors—Mechanical Design

Energy storage flywheel systems are mechanical devices that typically utilize an electrical machine (motor/generator unit) to convert electrical energy in mechanical energy and vice

Get Price

What is the capacity of flywheel energy storage? | NenPower

In summary, the capacity of flywheel energy storage is influenced by multiple core factors such as energy density, duration of energy release, and continuous technological

Get Price

Flywheel Design and Sizing Calculation Example

Flywheel inertia/size depends upon the fluctuations in speed. The difference between maximum & minimum speeds during a cycle is called

Get Price

Understanding Flywheel Energy Storage: Does High-Speed

This paper will review how energy is stored in a flywheel using the simple concept of a massive ball attached to a limited strength string. This concept will also be used to better understand

Get Price

Flywheel Energy Storage Systems | Electricity Storage Units

This flywheel, when paired to a motor/generator unit, behaves like a battery and energy can be stored for hours and dispatched on demand. The system service life is 20 years, without limits

Get Price

Mechanical Design Calculations of Flywheel Generator

Abstract. Flywheels generator is suited where a pulsed current generation is re- quired. It has a higher energy density as compared to capacitor banks. This paper focuses on design

Get Price

Flywheels

The energy storage system involving a flywheel as its primary unit is called a Flywheel Energy Storage system (FES). Flywheels are used to balance up the energy flow from a smooth

Get Price

Overview of Flywheel Systems for Renewable Energy

storage systems (FESS) are summarized, showing the potential of axial-flux permanent-magnet (AFPM) machines in such applications. Design examples of high-speed AFPM machines a e

Get Price

Flywheel Energy Storage | Energy Engineering and

The flywheel energy storage system is useful in converting mechanical energy to electric energy and back again with the help of fast

Get Price

Design of flywheel energy storage device with high specific energy

A lexicographic optimization scheme is formulated to define the flywheel power set-points by minimizing the transformer power limit violations and the flywheel energy losses.

Get Price

Flywheel Energy Storage Systems | Electricity

This flywheel, when paired to a motor/generator unit, behaves like a battery and energy can be stored for hours and dispatched on demand. The system

Get Price

ANALYSIS AND OPTIMIZATION OF FLYWHEEL

The concept of a flywheel is as old as the axe grinder''s wheel, but could very well hold the key to tomorrow''s problems of efficient energy storage. The flywheel has a bright outlook because of

Get Price

Design of flywheel energy storage device with high specific energy

Flywheel energy storage systems (FESSs) can reach much higher speeds with the development of technology. This is possible with the development of composite materials. In

Get Price

A review of flywheel energy storage systems: state of the art

Primary candidates for large-deployment capable, scalable solutions can be narrowed down to three: Li-ion batteries, supercapacitors, and flywheels. The lithium-ion

Get Price

قياس

قيم تجربتك مع نظام التسجيل في اختبارات مركز قياس تسعدنا مشاركتك معنا في تقييم تجربتك مع موقع التسجيل في اختبارات المركز الوطني للقياس عبر الرابط التالي:

Get Price

Numerical analysis of a flywheel energy storage system for low

The size of the air-gap is an important factor when designing a flywheel energy storage system [14], [15] which is dependent on various parameters including flywheel speed

Get Price

6 FAQs about [Maximum diameter of flywheel for flywheel energy storage]

What is a flywheel energy storage system?

First-generation flywheel energy-storage systems use a large steel flywheel rotating on mechanical bearings. Newer systems use carbon-fiber composite rotors that have a higher tensile strength than steel and can store much more energy for the same mass. To reduce friction, magnetic bearings are sometimes used instead of mechanical bearings.

How much energy can a flywheel store?

The small energy storage composite flywheel of American company Powerthu can operate at 53000 rpm and store 0.53 kWh of energy . The superconducting flywheel energy storage system developed by the Japan Railway Technology Research Institute has a rotational speed of 6000 rpm and a single unit energy storage capacity of 100 kW·h.

How to reduce the cost of Flywheel energy storage?

Therefore, the selection of appropriate rotor materials and the design of rotor structure are the key to reducing the cost of flywheel energy storage, which is crucial for the promotion of flywheel energy storage. Several review papers address different aspects of FESS research.

What is the energy storage Flywheel rated speed?

Dai Xingjian et al. designed a variable cross-section alloy steel energy storage flywheel with rated speed of 2700 r/min and energy storage of 60 MJ to meet the technical requirements for energy and power of the energy storage unit in the hybrid power system of oil rig, and proposed a new scheme of keyless connection with the motor spindle.

What is a 7 ring flywheel energy storage system?

In 1999 , the University of Texas at Austin developed a 7-ring interference assembled composite material flywheel energy storage system and provided a stress distribution calculation method for the flywheel energy storage system.

How do different flywheel structures affect energy storage density?

Different flywheel structures have important effects on mass distribution, moment of inertia, structural stress and energy storage density. Under a certain mass, arranging the materials as far away as possible from the center of the shaft can effectively improve the energy storage density of the flywheel rotor per unit mass.

More related information

-

Maximum efficiency of flywheel energy storage

Maximum efficiency of flywheel energy storage

-

Dynamic flywheel energy storage

Dynamic flywheel energy storage

-

Bangladesh flywheel energy storage construction costs

Bangladesh flywheel energy storage construction costs

-

Tunisian Flywheel Energy Storage Company

Tunisian Flywheel Energy Storage Company

-

Australian flywheel energy storage construction standards

Australian flywheel energy storage construction standards

-

Large-capacity flywheel energy storage system products

Large-capacity flywheel energy storage system products

-

Flywheel Energy Storage in Brazil

Flywheel Energy Storage in Brazil

-

Burkina Faso Flywheel Energy Storage

Burkina Faso Flywheel Energy Storage

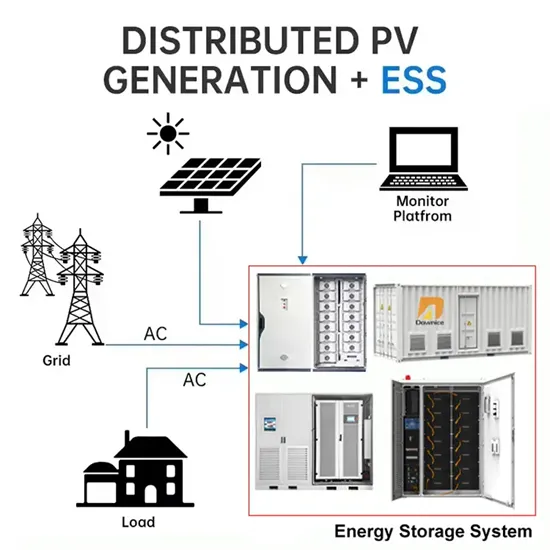

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.