12V vs 24V Inverter: What''s the difference between 12 and 24 Volt

The difference between a 12V and 24V inverter is the amount of input volts it can handle. This is the voltage flowing from the battery into the inverter before the electricity is converted from DC

Get Price

Frequently Asked Questions about Inverters

In this article, we''ll explore the key differences between 12V and 24V inverters, helping you make an informed decision for your specific application.

Get Price

Inverter loss: 12-volt vs 120-volt power usage

Inverter loss: 12-volt vs 120-volt energy usage As promised here''s my battery usage test comparing the run time of a Vitrifrigo fridge/freezer on

Get Price

Frequently Asked Questions about Inverters

Mastervolt sine wave inverters have an output efficiency of more than 92 %, which is the maximum that can be achieved with modern technology. If you connect an 850 W coffee

Get Price

Inverter loss: 12-volt vs 120-volt power usage

In this second scenario we have both an inverter in the Jackery running to step the 12 volts up to 120 volts AC, and a power supply brick running to convert the 120 volts AC back

Get Price

What Will An Inverter Run & For How Long? (With

Introduction - How does an inverter work? Our batteries store power in DC (Current current) but most of our household appliances require

Get Price

Electrical Tutorial

An inverter/charger also has a 12 volt DC battery input and a 120 volt AC power output. These units are larger so they are generally hard-wired into the

Get Price

32 Common Faults in Inverters and Their Solutions

When the inverter is in operation, a low output voltage from a unit can lead to a three-phase output imbalance, resulting in an over-voltage unit alarm. During the

Get Price

CSM_Inverter_TG_E_1_1

Vector Control Vector control is used to correct the output waveform according to the voltage and current output from the inverter to an induction motor. The motor speed and output torque are

Get Price

12V VS 24V Inverter: What are the Differences and How to Choose

In this article, we''ll explore the key differences between 12V and 24V inverters, helping you make an informed decision for your specific application.

Get Price

Understanding Inverter Voltage: Definition, Functions,

The term inverter voltage in electric power systems world is a familiar thing. However, some people still do not understand what an inverter

Get Price

12V vs 24V Inverters Key Differences and Which One is Right for

Voltage affects the overall performance of the inverter system. A 12V inverter is designed to handle lower power output and is typically suited for smaller applications, while a

Get Price

12 Volt DC Power Inverter: In-Depth Learning and Buying Guide

A 12-volt DC power inverter is an essential device for converting 12V direct current (DC) from a battery into 120V alternating current (AC), allowing you to power standard

Get Price

Complete Beginners Guide to 12v to 240v Inverter

What is a 12V to 240V Inverter? A 12V to 240V inverter is a device that converts direct current (DC) from batteries into alternating current (AC).

Get Price

How Many Amps Does a 1000 Watt Inverter Draw?

Is your 1000 watt inverter enough? Use these simple calculations to find out how many amps a 1000 watt inverter can draw.

Get Price

inverter No AC Output Solved

An inverter converts DC (direct current) into AC (alternating current), which makes it useful for solar powered homes and RVs. But what happens when

Get Price

Inverter Battery Voltage Chart

An inverter battery voltage chart shows the relationship between a battery''s charge level and its voltage. Battery voltage charts describe the

Get Price

Troubleshooting Inverter Problems: A Step-by-Step Guide

Inverters play a crucial role in many modern systems, converting DC power from sources like batteries or solar panels into AC power that can be used by household

Get Price

12V vs 24V Inverter: What''s The Difference & Which is Better

This article will explore the pros and cons of 12 voltage inverters vs 24 voltage inverters, considering factors such as energy loss, battery requirements, and suitability for different

Get Price

Inverter Current Calculator

Power is the output power of the inverter (in watts) Voltage is the DC input voltage of the inverter system (in volts) If you''re working with kilowatts (kW), convert it to watts before calculation:

Get Price

Frequently Asked Questions About Power Inverters | DonRowe

The inverter draws its power from a 12 Volt battery (preferably deep-cycle), or several batteries wired in parallel. The battery will need to be recharged as the power is drawn out of it by the

Get Price

12V vs 24V Inverter: What''s the difference between 12

The difference between a 12V and 24V inverter is the amount of input volts it can handle. This is the voltage flowing from the battery into the inverter before the

Get Price

How Does A 12V To 110v Inverter Work? – leaptrend

A 12V to 110V inverter is an immensely practical device that converts low-voltage direct current into high-voltage alternating current

Get Price

[SOLVED]

I have a 230VAC inverter that is only giving me about 197VAC with no load, and about the same voltage with load. on a three light voltage tester only the center light

Get Price

Understanding inverter voltage

The Tycorun 3000w inverter boasts a rated input voltage of 12V, making it compatible with standard 12-volt battery systems. Its input voltage range is between 9.5

Get Price

Inverter loss: 12-volt vs 120-volt power usage

In this second scenario we have both an inverter in the Jackery running to step the 12 volts up to 120 volts AC, and a power supply brick

Get Price

Understanding inverter voltage

The Tycorun 3000w inverter boasts a rated input voltage of 12V, making it compatible with standard 12-volt battery systems. Its input voltage

Get Price

Inverters Guide

Once you know the power consumption you can select an inverter that has an adequate output power, and we recommend selecting one that has an output power 50-100%

Get Price

6 FAQs about [Does the inverter output 12 volts ]

What is the difference between a 12V and 24V inverter?

The difference between a 12V and 24V inverter is the amount of input volts it can handle. This is the voltage flowing from the battery into the inverter before the electricity is converted from DC to AC. So a 12V inverter is designed for 12 volts input from the battery. And a 24V inverter is designed for 24 volts input from the battery.

What voltage is a 12V inverter?

Inverters come in various configurations, each designed for specific power systems. Common rated input voltages include 12V, 24V, and 48V. The choice depends on the application, the size of the power system, and the available power source. A 12V inverter is commonly used for smaller applications, such as in vehicles or small off-grid setups.

Can a 12V inverter run on a 24v battery?

If you try to use a 12V inverter on a 24V battery it will be overloaded. Contrastingly, using a 24V inverter with a 12V battery will lead to a lack of electrical force. Knowing your inverter's voltage and what that means is critical in order for everything to run correctly.

What is efficiency in a 12V inverter?

Efficiency refers to how effectively DC power is converted to AC, impacting system performance and operating costs. 12V Inverters: Common in smaller setups, 12V inverters often face efficiency challenges due to higher current requirements, leading to energy loss through heat and voltage drop.

How much power does an inverter use?

An inverter uses a small amount of energy during the conversion process. The difference between the input power and the output power is expressed in percentages. The efficiency of modern inverters is more than 92 %. This means that a maximum of 8 % of the power consumption is used to convert battery voltage to 230V/50Hz.

Which 12V power inverter is best?

For reliability and performance, Topbull 12V power inverters are highly recommended. Known for their robust design and superior efficiency, Topbull's inverters provide stable power for a wide range of applications. Here are three excellent options.

More related information

-

How many volts does a 60v inverter output

How many volts does a 60v inverter output

-

Inverter 12 to 72 volts 3kw

Inverter 12 to 72 volts 3kw

-

Inverter output voltage is over 1 000 volts

Inverter output voltage is over 1 000 volts

-

How many volts does a 5kw inverter usually have

How many volts does a 5kw inverter usually have

-

Charging inverter 12 volt

Charging inverter 12 volt

-

Is it normal for the inverter to output 246V AC voltage

Is it normal for the inverter to output 246V AC voltage

-

How many volts can the inverter withstand

How many volts can the inverter withstand

-

12 Inverter pure sine wave

12 Inverter pure sine wave

Commercial & Industrial Solar Storage Market Growth

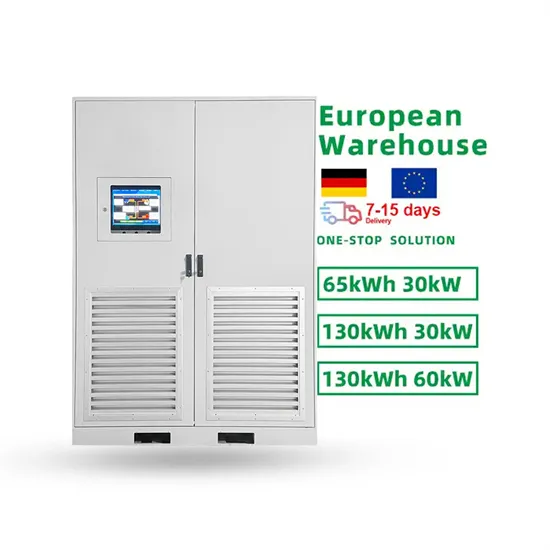

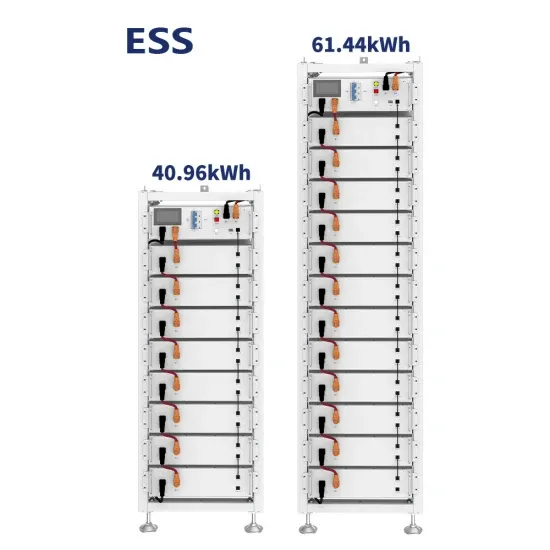

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.