Step-by-Step Battery Capacity Testing Procedure

Step-1: Ensure instrumentation is operational & properly connected to the battery for continuous monitoring of discharge voltage and

Get Price

How To Test A Battery Using A Digital Multimeter: Step By Step

How To Test a battery using a digital multimeter Testing a battery is a simple process when you have a digital multimeter to hand. The test will involve a number of steps

Get Price

How to Test a Battery Using a Multimeter-Step by Step Guide

Turn on the battery power or complete the circuit connection. The multimeter displays the current flowing from the battery through the load in amperes (A) or milliamperes (mA).

Get Price

How to Measure Battery with Multimeter? A Step-by-Step Guide

In summary, a battery is a device that converts chemical energy into electrical energy, and a multimeter is a versatile tool for measuring electrical parameters like voltage,

Get Price

Electric battery

An electric battery is a source of electric power consisting of one or more electrochemical cells with external connections [1] for powering electrical

Get Price

Understanding Battery Current: How It Works, Measurement

In this article we are going to discuss what is battery current, how to measure it, factors affecting it, its impact on performance and lifespan, and its applications in everyday life.

Get Price

How to Check Battery Amps with a Multimeter

Learn how to check battery amps with a multimeter. A step-by-step guide to ensure accurate readings and battery health.

Get Price

DIY 18650 Li-Ion Battery Capacity and Discharge

Battery Capacity (mAh) = Current (I ) in mA x Time ( T ) in Hours To calculate the battery capacity (mAh) using the above equation, we have to

Get Price

Understanding Battery Capacity: Measurement And

Measure the current: Use a data acquisition system or a microcontroller with an analog-to-digital converter (ADC) to measure the

Get Price

How to Measure Current of a Battery Using Multimeter? A Simple

This detailed guide will equip you with the knowledge and practical steps needed to accurately measure battery current using a multimeter, covering various scenarios, potential

Get Price

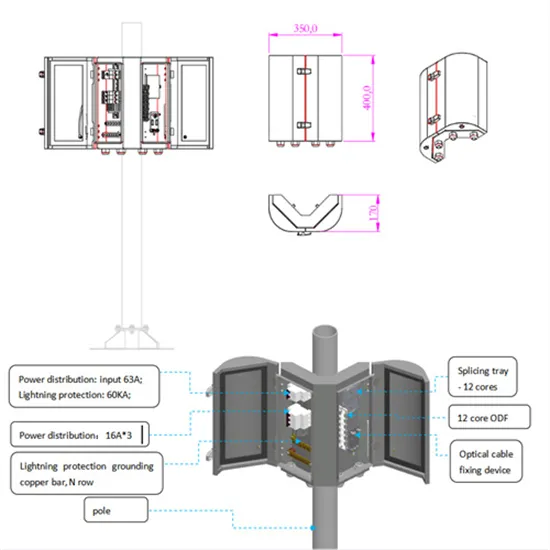

SmartGen HGM4020T Generator controller. Communication Base Station

8. Precision measure and display parameters about Engine. 9. Machine room temperature can be collected, if temperature is too high, air conditioner in the machine will be started; 10. Battery

Get Price

How to Test a Battery Using a Multimeter-Step by

Turn on the battery power or complete the circuit connection. The multimeter displays the current flowing from the battery through the load in amperes (A)

Get Price

Learn How to Test a Battery Using a Multimeter

You can measure battery current using a multimeter by setting it to the ammeter function and connecting it in series with the circuit. This allows you to accurately gauge how

Get Price

Ensure Your Base Station Transmitter Complies with 5G NR

Base stations must now pass new conformance tests to ensure they deliver on their promises. Performing conformance testing is an important part of the base station lifecycle, which

Get Price

How to Maintain Your Station Batteries Part III Current and

Continuing with our look into station battery maintenance, let''s explore the value of measuring and/or monitoring flowing currents and connection resistances. Excessive current

Get Price

How to Test Batteries With a Multimeter: DIY Guide for Accuracy!

To check battery current accurately, you need to guarantee the battery is disconnected from any external circuit, which prevents interference during the measurement.

Get Price

Understanding Battery Current: How It Works,

In this article we are going to discuss what is battery current, how to measure it, factors affecting it, its impact on performance and lifespan, and

Get Price

How Can You Measure Battery Current Using a Multimeter?

You can measure battery current using a multimeter by setting it to the ammeter function and connecting it in series with the circuit. This allows you to accurately gauge how

Get Price

How to Do a Battery Discharge Test

A battery discharge test helps evaluate a battery''s performance and health by measuring its voltage and capacity under controlled discharge conditions. Using a Battery

Get Price

How to Measure Battery with Multimeter? A Step-by-Step Guide

Measuring Current: Measure the current flowing through a circuit to understand the power consumption. Disconnect the battery from the circuit, connect the multimeter in series

Get Price

Simplify Voltage and Current Measurement in Battery Test

Depending on the output current requirements, the buck-boost functions can be accomplished several ways; however, two approaches are the most common. For higher current

Get Price

Understanding State of Charge (SOC) for Optimal

How to monitor SOC levels One of the most common methods for monitoring SOC is to use a battery management system (BMS). A BMS is an

Get Price

How to Measure Car Battery Current with Multimeter? Easy Steps

The importance of measuring car battery current with a multimeter cannot be overstated. A car battery is a critical component of a vehicle''s electrical system, and its health

Get Price

Learn How to Test a Battery Using a Multimeter

To measure the current, one must create a circuit where the multimeter is in series with the battery and a load. A resistor has a fixed resistance (assuming temperature remains

Get Price

How to Test Batteries With a Multimeter: DIY Guide

To check battery current accurately, you need to guarantee the battery is disconnected from any external circuit, which prevents interference

Get Price

How To Measure Current Of Battery Using Multimeter? A Simple

Understanding the current output of a battery is crucial for a wide range of applications, from simple electronics projects to complex industrial systems.

Get Price

6 FAQs about [How to measure the battery current of a base station]

How do you measure a battery?

Measuring Current: Measure the current flowing through a circuit to understand the power consumption. Disconnect the battery from the circuit, connect the multimeter in series with the circuit, and select the appropriate current setting and range. Measuring Resistance: Measuring internal resistance reveals a battery’s internal health.

How to measure the current output of a battery with a multimeter?

To measure the current output of a battery with a multimeter, follow these steps: 1. Prepare the Battery and Multimeter Disconnect the battery from any circuit. This prevents interference during measurement. 2. Set Up the Multimeter Switch the multimeter to measure DC current. Choose the range based on the expected current.

How to check battery current accurately?

To check battery current accurately, you need to guarantee the battery is disconnected from any external circuit, which prevents interference during the measurement. Follow these steps for precise results: Set your multimeter to the appropriate DC current range.

How do you test a battery?

Read the voltage level of the battery with a digital multimeter or hydrometer-style battery tester. Measure the current flow with the multimeter. Disconnect the multimeter and turn off the electrical system of the device. Reconnect the negative terminal of the battery.

How do you test a battery with a multimeter?

Connect the multimeter in series with the circuit so that the current flows through the multimeter for an accurate reading. Ensure your multimeter is rated to handle the expected amperage of the battery before proceeding with the test. Multimeters have several functions, including measuring volts, ohms, and amps.

What does a battery multimeter measure?

The reading on the multimeter indicates the instantaneous current being drawn from the battery by the connected load at that moment. This measurement reflects the battery's ability to supply current under the specific conditions of the test, not its total capacity (Ah or mAh).

More related information

-

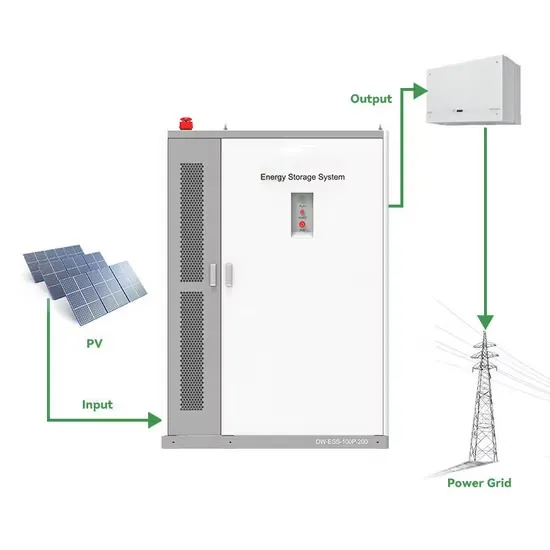

How to use weak current backup battery cabinet with ESS power base station

How to use weak current backup battery cabinet with ESS power base station

-

How to check the battery of 5G base station

How to check the battery of 5G base station

-

How big a base station should I buy a battery cabinet for

How big a base station should I buy a battery cabinet for

-

How much battery capacity does the base station use

How much battery capacity does the base station use

-

How big is the liquid flow battery in mobile base station equipment

How big is the liquid flow battery in mobile base station equipment

-

How much does a base station battery cost

How much does a base station battery cost

-

Base station battery output current direction

Base station battery output current direction

-

How is the battery of Croatia Telecom base station

How is the battery of Croatia Telecom base station

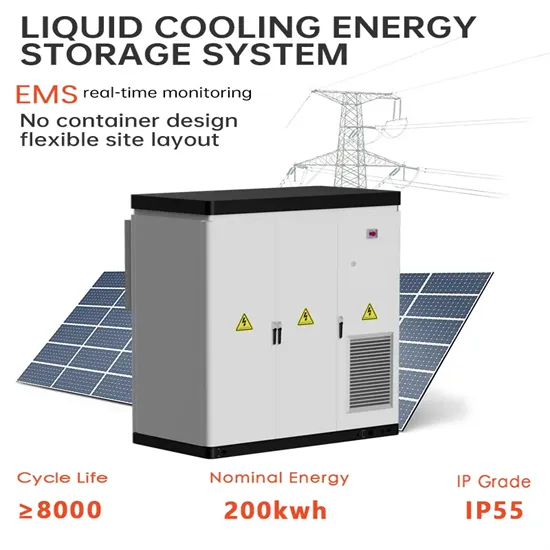

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.