Air Cooling vs. Liquid Cooling of BESS: Which One Should You

When it comes to managing the thermal regulation of Battery Energy Storage Systems (BESS), the debate often centers around two primary cooling methods: air cooling

Get Price

GSL Energy: Leading Provider of Efficient Battery

Discover efficient energy storage solutions with GSL Energy''s advanced battery storage systems and solar batteries. As a top LiFePO4

Get Price

Optimization design for improving thermal performance of T-type air

In order to solve the problems of high battery temperature and poor temperature uniformity of the battery pack in the process of high-intensity operation, an air-cooled T-type

Get Price

Thermal Battery Storage Systems | Trane Commercial HVAC

The Trane® Thermal Battery air-cooled chiller plant is a thermal energy storage system, which can make installation simpler and more repeatable, saving design time and construction costs.

Get Price

Battery Energy Storage Systems Cooling for a sustainable

a sustainable future Solutions Systems The Pfann nberg Battery Cooling Solutions maintain battery packs at an optimum average temperature. They are suitable for ambient temperatures

Get Price

Optimizing thermal performance in air-cooled Li-ion battery

These results highlight the potential of air-cooled battery management systems as a viable solution for effective TMS in battery applications, warranting further exploration and

Get Price

How Can Liquid Cooling Revolutionize Battery Energy

Liquid-cooled energy storage systems significantly enhance the energy efficiency of BESS by improving the overall thermal conductivity of the system. This

Get Price

Comparative assessment and optimization among several

Plenum shape and position play a significant impact on the heat dissipation performance of battery pack with air-cooled structure. However, the existe

Get Price

Research on air‐cooled thermal management of energy storage lithium battery

Battery energy storage system occupies most of the energy storage market due to its superior overall performance and engineering maturity, but its stability and efficiency are

Get Price

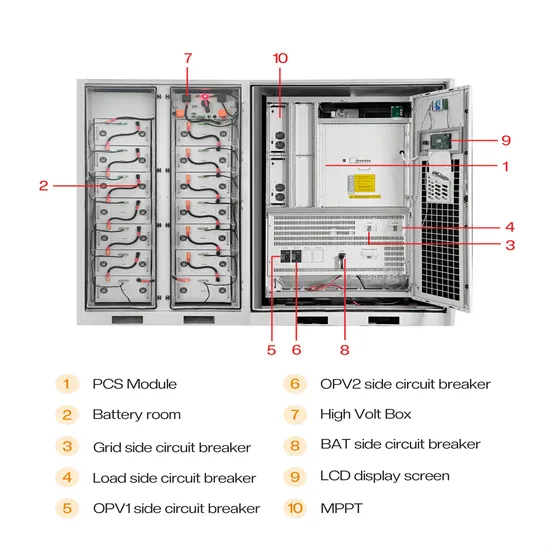

Air-cooled C&I BESS Energy Storage Cabinet | AZE

An air-cooled C&I (Commercial and Industrial) Battery Energy Storage System (BESS) cabinet is a type of energy storage solution designed for commercial and industrial applications.

Get Price

Optimization study of air-cooled stagger-arranged battery pack

For low cost and environmental adaptability, the air-cooling system has been widely used as the thermal management system and is being discussed in more and more

Get Price

A review of air-cooling battery thermal management systems for electric

Then the basic air-cooling BTMS design is reviewed, and a variety of novel design improvements is evaluated to explore the benefits and challenges of the use of the air-cooling

Get Price

Optimized thermal management of a battery energy-storage

For various cooling strategies of the battery thermal management, the air-cooling of a battery receives tremendous awareness because of its simplicity and robustness as a

Get Price

Design and Performance Optimization of an Air-Cooled Battery

As global energy concerns and environmental challenges intensify, the automotive industry is rapidly transitioning toward more sustainable solutions, with new energy vehicles,

Get Price

Comparison of cooling methods for lithium ion battery pack heat

Comparison of cooling methods for lithium ion battery pack heat dissipation: air cooling vs. liquid cooling vs. phase change material cooling vs. hybrid cooling In the field of

Get Price

Research on air‐cooled thermal management of energy storage

Battery energy storage system occupies most of the energy storage market due to its superior overall performance and engineering maturity, but its stability and efficiency are

Get Price

Air Cooling Battery Systems for Versatile and Scalable Energy Storage

Air cooling battery systems provide a versatile and efficient solution for commercial, industrial, and off-grid energy storage applications. Offering a combination of cost

Get Price

Air-Cooled Battery Energy Storage System

Tutorial model of an air-cooled battery energy storage system (BESS). The model includes conjugate heat transfer with turbulent flow, fan curves, internal

Get Price

A review of air-cooling battery thermal management systems for electric

Battery Thermal Management System (BTMS) is critical to the battery performance, which is important to the overall performance of the powertrain system of Electric Vehicles

Get Price

Battery Cooling Tech Explained: Liquid vs Air Cooling Systems

Air cooling remains viable for low-C-rate or cost-sensitive systems like small BESS, legacy UPS, etc., while liquid cooling is the de facto solution for high-performance EVs and

Get Price

What are the models of energy storage air-cooled batteries?

Based on the exploration of energy storage solutions, the models of air-cooled batteries include 1. Lead-acid batteries, 2. Lithium-ion batteries, 3. Flow batteries, and 4.

Get Price

Air-Cooled vs. Liquid-Cooled Energy Storage Systems: Which

Both air-cooled and liquid-cooled energy storage systems (ESS) are widely adopted across commercial, industrial, and utility-scale applications. But their performance,

Get Price

What are the models of energy storage air-cooled

Based on the exploration of energy storage solutions, the models of air-cooled batteries include 1. Lead-acid batteries, 2. Lithium-ion batteries,

Get Price

Air-Cooled Battery Energy Storage System

Tutorial model of an air-cooled battery energy storage system (BESS). The model includes conjugate heat transfer with turbulent flow, fan curves, internal screens, and grilles.

Get Price

Surrogate model-based multiobjective design

2.1. Air-cooled battery pack structural design An energy storage battery pack (ESBP) with air cooling is designed for energy transfer in a fast-charging pile

Get Price

Air Cooling Battery Systems for Versatile and Scalable Energy

Air cooling battery systems provide a versatile and efficient solution for commercial, industrial, and off-grid energy storage applications. Offering a combination of cost

Get Price

Battery Cooling Tech Explained: Liquid vs Air Cooling

Air cooling remains viable for low-C-rate or cost-sensitive systems like small BESS, legacy UPS, etc., while liquid cooling is the de facto solution

Get Price

Thermal Battery Systems

Thermal Battery systems are Trane®-controlled chiller plants enhanced with CALMAC® thermal energy storage. The chiller plant operates like a battery: charging when excess or inexpensive

Get Price

A review of air-cooling battery thermal management systems for

Then the basic air-cooling BTMS design is reviewed, and a variety of novel design improvements is evaluated to explore the benefits and challenges of the use of the air-cooling

Get Price

6 FAQs about [Air-cooled battery energy storage]

What is a battery energy storage system?

Battery Energy Storage Systems (BESS) are essential for storing energy and ensuring its availability when needed. However, like all electronic systems, batteries generate heat during operation, especially when discharging or charging at high rates. Effective cooling is crucial to maintain the efficiency, safety, and longevity of these systems.

Which cooling method is best for battery energy storage systems?

When it comes to managing the thermal regulation of Battery Energy Storage Systems (BESS), the debate often centers around two primary cooling methods: air cooling and liquid cooling. Each method has its own strengths and weaknesses, making the choice between the two a critical decision for anyone involved in energy storage solutions.

What is an air cooled battery system?

Air-cooled systems use ambient air flow – fans or natural convection – to carry heat away from the cells. They are simple and low-cost, since no coolant, plumbing or pumps are needed. Air cooling avoids leak hazards and extra weight of liquids. As a result, smaller or lower-power battery installations often rely on air-cooled designs.

Are battery racks air cooled?

Most data-center battery racks are essentially air-cooled by the existing HVAC system. The old standard air-cooled lead-acid backup already relied on ambient airflow. Now, even the lithium UPS is more tolerant of temperature.

Why is thermal management of battery energy storage important?

Dongwang Zhang and Xin Zhao contributed equally to this work. Battery energy storage system occupies most of the energy storage market due to its superior overall performance and engineering maturity, but its stability and efficiency are easily affected by heat generation problems, so it is important to design a suitable thermal management system.

Do EV batteries need air cooling?

Nissan’s first-generation Leaf, for example, relied on ambient air flow. However, a 100 kWh battery can generate on the order of 5 kW of waste heat under heavy load, which requires more efficient liquid-cooling system. In practice, air-cooled EV packs are limited to very low-power use.

More related information

-

Wall-mounted energy storage lithium battery air-cooled energy storage cabinet

Wall-mounted energy storage lithium battery air-cooled energy storage cabinet

-

Air-cooled battery energy storage

Air-cooled battery energy storage

-

Venezuela s dedicated energy storage battery company

Venezuela s dedicated energy storage battery company

-

Home 5kwh energy storage battery pack

Home 5kwh energy storage battery pack

-

Base station energy storage battery structure base station

Base station energy storage battery structure base station

-

Laos energy storage battery wholesaler

Laos energy storage battery wholesaler

-

South Sudan We Battery Energy Storage Power Station

South Sudan We Battery Energy Storage Power Station

-

Pakistan Enterprise Energy Storage Battery Model

Pakistan Enterprise Energy Storage Battery Model

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.