PV Solar Cell Manufacturing Process & Equipment Explained

Explore the solar module manufacturing process in detail and discover how Smartech''s solutions enhance efficiency in PV cell production.

Get Price

Solar panel production equipment and machinery

Discover the latest Solar panels'' production & testing machines from Ecoprogetti Srl by clicking here. Solar panel production equipment and machinery. Nowadays the solar

Get Price

How to manufacture a photovoltaic module

The photovoltaic cells are placed in a piece of equipment, called solar stringer, that interconnects the cells in a series by soldering a coated copper wire, called ribbon, on the bus bar of the cell.

Get Price

Up-to-date literature review on Solar PV systems: Technology

According to market estimates, the cost of solar PV panels has decreased by nearly 67% over the last decade. Rising PV demand in Europe boosted the global PV industry

Get Price

Solar photovoltaic panel processing equipment

The manufacturing process of PV solar cells necessitates specialized equipment, each contributing significantly to the final product''s quality and efficiency: Silicon Ingot and Wafer

Get Price

Photovoltaics

SINGULUS TECHNOLOGIES provides production equipment for photovoltaics: for both crystalline and thin-film high-performance solar cell platforms including CIGS, CdTe and

Get Price

NPC incorporated | Global leader of solar module manufacturing

We have accumulated high technology in PV industry from development and sales of PV module manufacturing equipment to panel reuse/recycling. Now we provide it for a variety of industries

Get Price

Suniva -America''s Leading Solar Cell Manufacturer

Suniva is America''s oldest and largest monocrystalline solar cell manufacturer in North America. Suniva was founded in 2007, out of one of the

Get Price

PV Management Solar Panel Recycling Solutions | ERI

Installations vary in size from a couple of panels on residential home to a complete commercial solar farm, covering acres of ground. ERI services are

Get Price

Photovoltaics

SINGULUS TECHNOLOGIES provides production equipment for photovoltaics: for both crystalline and thin-film high-performance solar cell platforms including

Get Price

Solar Cell Production: from silicon wafer to cell

Producers of solar cells from silicon wafers, which basically refers to the limited quantity of solar PV module manufacturers with their own wafer-to-cell production equipment

Get Price

Solar Ingot / Wafer / Cell / Panel Equipment Manufacturers

List of solar production equipment manufacturers. A complete list of companies that make equipment used to produce solar ingots, wafers, cells or panels.

Get Price

PV Solar Cell Manufacturing Process & Equipment

Explore the solar module manufacturing process in detail and discover how Smartech''s solutions enhance efficiency in PV cell production.

Get Price

Industrial Equipment for Solar Panel Manufacturing

Epcon Industrial Systems provides custom-engineered thermal processing equipment and air pollution control solutions designed to optimize solar panel

Get Price

NPC incorporated | Global leader of solar module manufacturing equipment

We have accumulated high technology in PV industry from development and sales of PV module manufacturing equipment to panel reuse/recycling. Now we provide it for a variety of industries

Get Price

Top 24 Photovoltaic Equipment Producers Worldwide

Discover the top 24 global photovoltaic equipment manufacturing companies shaping the renewable energy landscape. This article profiles companies like Trina Solar and JA Solar,

Get Price

G-Star Pte.Ltd. | solar photovoltaic panels | solar

G-STAR is a technology-based enterprise specializing in photovoltaic power generation solutions, realizing vertically integrated R&D, design, production

Get Price

Industrial Equipment for Solar Panel Manufacturing

Epcon Industrial Systems provides custom-engineered thermal processing equipment and air pollution control solutions designed to optimize solar panel production while ensuring

Get Price

Solar Panel Manufacturing: A Comprehensive Guide

Introduction to Solar Panel Manufacturing Solar panel manufacturing is the process of producing photovoltaic (PV) panels used to

Get Price

Top 24 Photovoltaic Equipment Producers Worldwide

The photovoltaic equipment manufacturing industry is a growing field with a pivotal role in our switch to renewable energy. The industry consists of companies that engineer, produce, and

Get Price

NPC incorporated | Global leader of solar module

1. High technology accumulated in PV industry and ability of applying it to new industries We have accumulated high technology in PV industry from

Get Price

Solar photovoltaic recycling strategies

This paper overviews the commitment level of different countries to solar PV recycling. It summarizes the various solar PV recycling strategies for different types of solar

Get Price

Photovoltaic Manufacturing Equipment | PV Manufacturing

Find high quality photovoltaic manufacturing equipment from Chemcut. PV manufacturing systems are custom made for Solar Panels and more. Contact us today.

Get Price

Solar panels manufacturing machines: our proposal

Published: 20 July 2016 2022-> Discover the latest Solar panels'' production & testing machines from Ecoprogetti Srl by clicking here. FROM 20

Get Price

Solar panel manufacturing equipment,Fuly automatic

This equipment is ideal for solar PV module manufacturers, enabling efficient sorting and analysis of solar cells based on electrical performance. It ensures

Get Price

Top 10 Solar Panel Manufacturers in India in 2025

In this blog, we have listed top solar manufacturers in India. We have concluded this list from the top manufacturers and fetched the best

Get Price

Specialist in Solar Panel Manufacturing Equipment | Horad

We offer a complete set of PV machines covering all solar manufacturing processes. We offer complete solar panel production lines for global customers to manufacture photovoltaic

Get Price

Solar panel manufacturers in China

This has solidified the country''s position as an undisputed leader in the solar field. What''s more, China proudly hosts the world''s top ten suppliers

Get Price

Solar panel manufacturing equipment,Fuly automatic solar cell

This equipment is ideal for solar PV module manufacturers, enabling efficient sorting and analysis of solar cells based on electrical performance. It ensures only high-quality cells are used in

Get Price

6 FAQs about [Photovoltaic solar panel equipment processing manufacturer]

Where can I find the latest solar panels production & testing machines?

Discover the latest Solar panels’ production & testing machines from Ecoprogetti Srl by clicking here. Solar panel production equipment and machinery Nowadays the solar panels’ production equipment is divided into the following required machinery and accessories.

How are solar panels manufactured?

Nowadays the solar panels’ production equipment is divided into the following required machinery and accessories. The first run automated processes are the stringing and lamination, but also the analysis of quality as electroluminescence tests. These and other procedures are indispensable for the correct manufacture of the module in each component.

How are PV solar cells made?

The manufacturing process of PV solar cells necessitates specialized equipment, each contributing significantly to the final product’s quality and efficiency: Silicon Ingot and Wafer Manufacturing Tools: These transform raw silicon into crystalline ingots and then slice them into thin wafers, forming the substrate of the solar cells.

What is a photovoltaic (PV) solar cell?

Central to this solar revolution are Photovoltaic (PV) solar cells, experiencing a meteoric rise in both demand and importance. For professionals in the field, a deep understanding of the manufacturing process of these cells is more than just theoretical knowledge.

How are solar modules manufactured?

Assembly and Testing: The cells are assembled into modules and undergo thorough testing for efficiency and durability, ensuring they meet the high standards required for solar energy applications. Solar photovoltaic lamination stands as an important step in the solar module manufacturing process.

Do you offer a complete set of PV machines?

We offer a complete set of PV machines covering all solar manufacturing processes. We offer complete solar panel production lines for global customers to manufacture photovoltaic modules based on their specific requirements.

More related information

-

Vanuatu Solar Photovoltaic Panel Production Equipment Manufacturer

Vanuatu Solar Photovoltaic Panel Production Equipment Manufacturer

-

Farmland photovoltaic panel installation equipment manufacturer

Farmland photovoltaic panel installation equipment manufacturer

-

Afghanistan photovoltaic panel equipment manufacturer

Afghanistan photovoltaic panel equipment manufacturer

-

Hungarian photovoltaic conductive solar panel manufacturer

Hungarian photovoltaic conductive solar panel manufacturer

-

Bhutan silicon solar photovoltaic panel manufacturer

Bhutan silicon solar photovoltaic panel manufacturer

-

Which solar photovoltaic panel manufacturer is best in Panama

Which solar photovoltaic panel manufacturer is best in Panama

-

Selling solar photovoltaic panel production equipment standards

Selling solar photovoltaic panel production equipment standards

-

Benin photovoltaic solar panel manufacturer

Benin photovoltaic solar panel manufacturer

Commercial & Industrial Solar Storage Market Growth

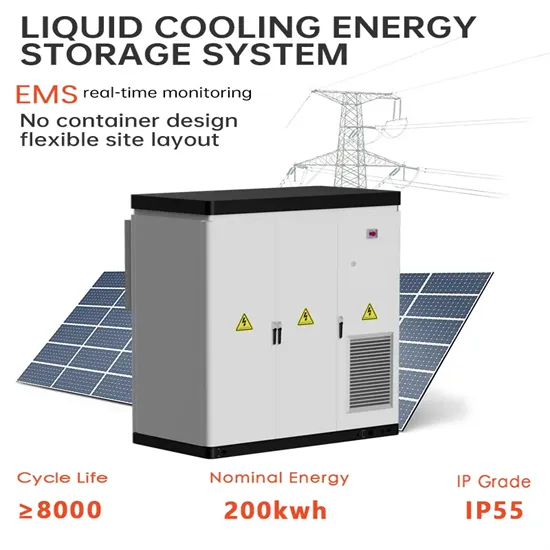

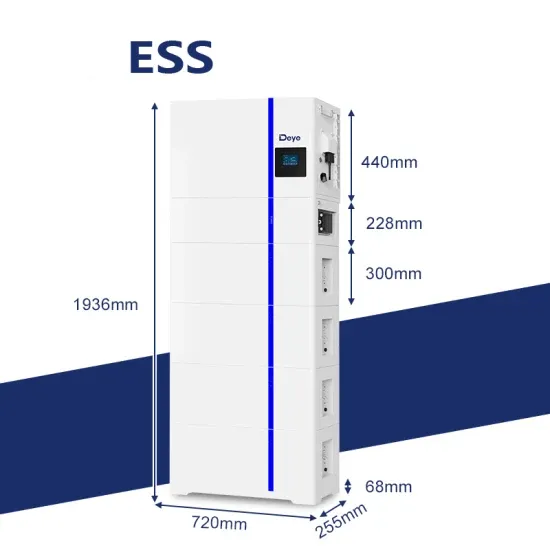

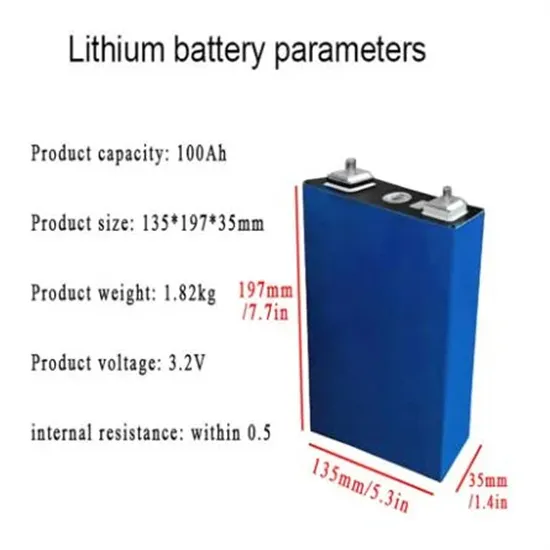

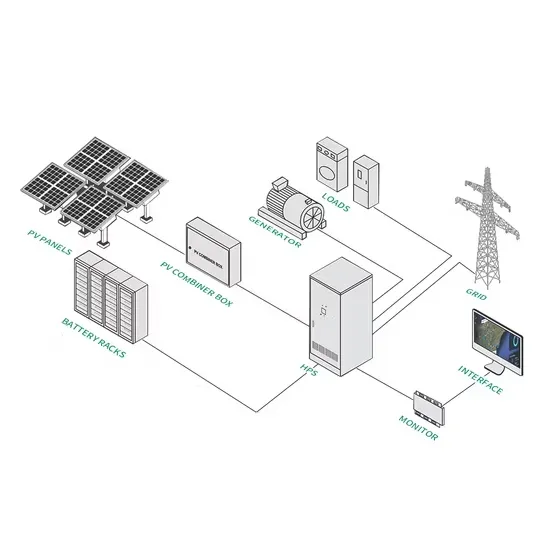

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.