Variable Frequency Drive (VFD) | Rockwell

Our PowerFlex® 755T low voltage variable frequency drives are designed to provide harmonic mitigation, regeneration, and common bus solutions that

Get Price

High Voltage High Frequency AC

Looking for high frequency inverter/converter? Micno''s high voltage power inverter (vtd) can be used for energy-saving speed regulation and process

Get Price

High Voltage High Frequency AC Drives/Inverter/Converter

Looking for high frequency inverter/converter? Micno''s high voltage power inverter (vtd) can be used for energy-saving speed regulation and process improvement of high-voltage

Get Price

High-Frequency Variable Load Inverter Architecture

The invented high-frequency inverter system enables HF power delivery directly into highly variable impedance loads with a relatively high efficiency. A pair of inverters are coupled and

Get Price

High Voltage 11KV Variable Frequency Drive

High Voltage 11KV Variable Frequency Drive is designed to be highly reliable with high-performance, yet easy to use can satisfy users'' need for changing the speed of fans or

Get Price

High-Frequency Variable Load Inverter Architecture

Technology The invented high-frequency inverter system enables HF power delivery directly into highly variable impedance loads with a relatively high efficiency. A pair of inverters are coupled

Get Price

A High Frequency Variable Load Inverter Architecture

This thesis presents the design, physical prototype, controller, and experimental results of a high-frequency variable load inverter architecture (referred to as HFVLI) that can directly drive

Get Price

Research on High-Frequency Isolated NPC Three

Mining frequency converters are the primary means for achieving variable frequency speed regulation of electromechanical equipment in coal

Get Price

Low Voltage VFDs with High Performance and Energy Savings

Inomax Technologies'' low voltage variable frequency drives offer high performance and energy savings in a variety of applications. Check out the benefits of low-voltage VFDs to find the right

Get Price

Drives

Hitachi Hi-Rel''s Variable Frequency Drives represent the most energy efficient means of process control and reflect the best in process control. Hitachi Hi-Rel''s Variable Frequency Drives used

Get Price

A High Performance High Frequency Inverter Architecture with

In this work, a high frequency inverter system that can work in a wide range of inductive or capacitive load is proposed, which includes Class D inverter, novel

Get Price

A High Frequency Variable Voltage Fed Inverter

Abstract: This paper presents a half bridge inverter circuit capable of providing a wide range of ac output voltages and frequencies. The inverter offers other advantages, such as low snubber

Get Price

Power Frequency Inverters for High Voltage Tests

Two level voltage source inverters with connected resonant or filter circuits are normally used to generate a high-quality test voltage by feedback control. The properties of power fre-quency

Get Price

Voltage Fed Full Bridge DC-DC & DC-AC Converter High

This application report documents the implementation of the Voltage Fed Full Bridge isolated DC-DC converter followed by the Full-Bridge DC-AC converter using TMS320F28069 ( C2000TM)

Get Price

Nine-level high-frequency inverter | IET Power Electronics

Besides, the HFAC output can be achieved at a lower switching frequency for the maximum switching frequency is only double the output frequency. The detailed analysis on

Get Price

Guide to Frequency Inverters: Optimizing Motor

I. Introduction to Frequency Inverters (VFDs) Frequency inverters, also known as variable frequency drives (VFDs), are essential components in

Get Price

High Power Factor Induction Heating System with

At present application, cost effective induction heating (IH) using high frequency inverters have been gradually developed for the utility frequency ac to high-frequency ac power conversion

Get Price

Site Erlangen – Valeo Power Division | Valeo

The site is home to a center for the research and development of high-voltage electric technologies, especially for the inverters for (plug-in) hybrid and fully electric vehicles.

Get Price

Comparing Carrier-Based PWM Techniques in High

This article explores the potential of carrier-based pulse width modulation techniques such as sawtooth, triangular, and sinusoidal, and

Get Price

Variable Frequency Drives | Wolong America

WD4000 Medium Voltage Variable Frequency Drives (VFD) Wolong is a leading manufacturer of high-voltage drives with 25 years of experience and a global

Get Price

HE1000 High Voltage Variable Frequency Selection Guide

MICNO masters the leading synchronization, asynchronization current vector control technology, torque control technology and solar pump driving technology, including the main products such

Get Price

Variable Frequency Drives (VFD) | Sumitomo Invertek VFDs

What is a Variable Frequency Drive (VFD) ? A variable frequency drive (VFD) is an electronic device that controls the speed of AC induction motors. Another term for Variable Frequency

Get Price

Large disturbance stability evaluation of

In this paper, the large disturbance stability is evaluated for the multi-inverter system with VSG model. Proceeding from the perspective of

Get Price

High Frequency Inverter Schematic

High frequency inverters are electrical devices that are capable of converting a DC voltage to an AC voltage of the same frequency. Inverters are

Get Price

A High-Frequency Inverter for Variable-Load Operation

We present the underlying theory and design considerations for the proposed architecture along with a physical prototype and efficiency optimizing controller.

Get Price

Schaeffler starts volume production of its high voltage inverter brick

First large-scale production of high voltage inverter brick for leading Chinese automotive manufacturer Production ramp-up in Tianjin, China within just one year despite

Get Price

The difference between frequency converter and inverter

The inverter with adjustable frequency and voltage of the inverter power supply is called a frequency converter. The waveform output by the

Get Price

6 FAQs about [High-power high-voltage variable frequency inverter]

What is high frequency power inverter?

The high voltage frequency converter integrate the most advanced motor vector control algorithm, high control precision, fast response, low frequency, high torque. Our high frequency power inverter can be applied to energy-saving speed regulation and process improvement of high-voltage asynchronous motors and synchronous motors.

What is a high frequency variable load inverter architecture?

This thesis presents a high frequency variable load inverter architecture along with a physical prototype and e ciency optimizing controller. The inverter architecture consists of two constituent inverters, one connected directly through the load and the other connected through an immittance converter, which acts as a lossless power combiner.

What are the parts of a high frequency power inverter?

The high frequency power inverter includes two parts, main circuit and control circuit. The main circuit includes an inverter DC power supply, high frequency high voltage transformers, IGBT bridge inverter, protection circuits, high frequency high voltage silicon stack (Rectifier) , etc.

Can a high-frequency variable load inverter directly drive widely variable loads?

Typically a tunable matching network is used to transform the varying load into a ciency and impairing transient response. This thesis presents the design, physical prototype, controller, and experimental results of a high-frequency variable load inverter architecture (referred to as HFVLI) that can directly drive widely variable loads.

What is micno high voltage inverter?

MICNO high voltage inverter adopts the most mainstream power unit series technology, with DSP+ARM+FPGA three-core processor as the control core. The high voltage frequency converter integrate the most advanced motor vector control algorithm, high control precision, fast response, low frequency, high torque.

Is a new inverter architecture suitable for varying load impedances?

Abstract: This paper presents a new inverter architecture suitable for driving widely varying load impedances at high frequency (HF, 3-30 MHz) and above. We present the underlying theory and design considerations for the proposed architecture along with a physical prototype and efficiency optimizing controller.

More related information

-

Three-phase constant voltage variable frequency inverter

Three-phase constant voltage variable frequency inverter

-

Variable frequency inverter 12V

Variable frequency inverter 12V

-

High-voltage high-power energy storage inverter

High-voltage high-power energy storage inverter

-

Variable frequency inverter adjusts voltage

Variable frequency inverter adjusts voltage

-

Variable frequency DC inverter

Variable frequency DC inverter

-

The frequency on the high-voltage side of the inverter is too high

The frequency on the high-voltage side of the inverter is too high

-

Base station lithium battery with power frequency inverter

Base station lithium battery with power frequency inverter

-

What is the price of high frequency inverter

What is the price of high frequency inverter

Commercial & Industrial Solar Storage Market Growth

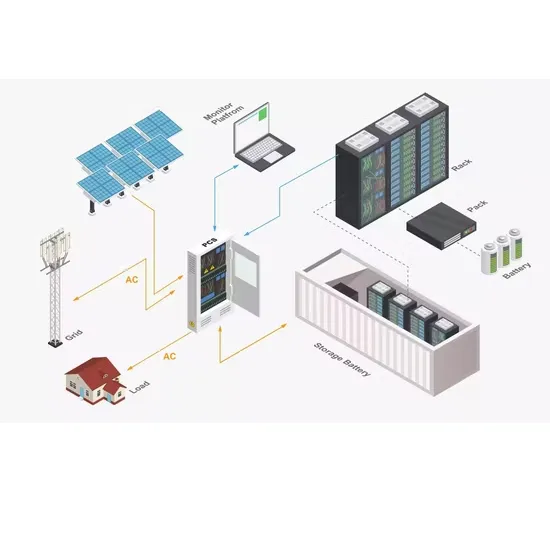

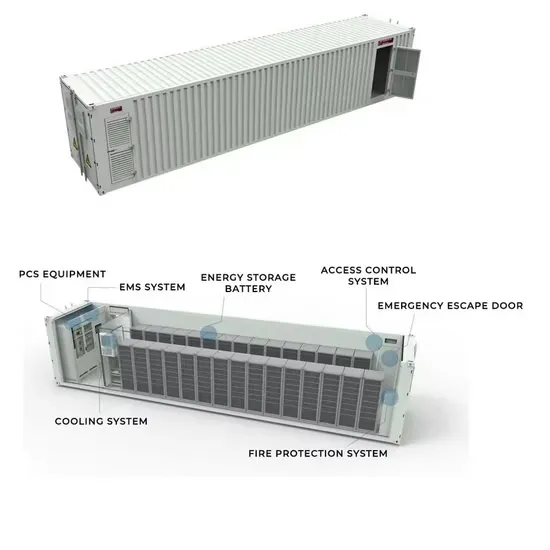

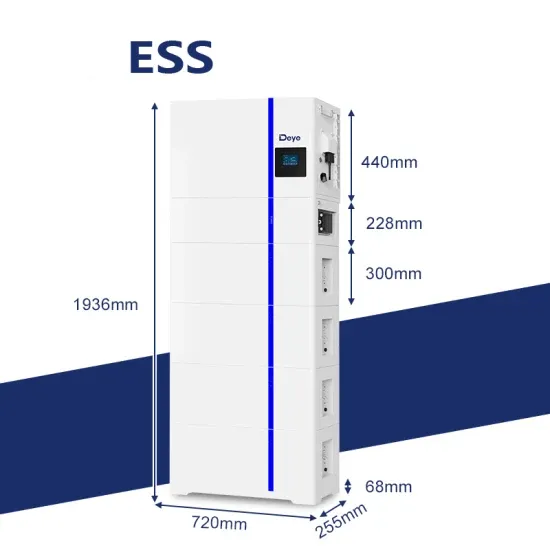

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.