Lead-Acid Battery Management System

Lead-acid BMSs are commonly used in EV and hybrid electric vehicles to power the starting, lighting and ignition (SLI) functions, but they can also be found in renewable energy

Get Price

Why Lead-Acid Batteries Need Battery Monitoring Systems to

To overcome these challenges, integrating a Battery Monitoring System (BMS) is essential. This article explores why lead-acid batteries need a BMS, how it enhances

Get Price

The most complete analysis of bms for lead acid battery

The battery management system (BMS) quickly and reliably monitors the state of charge (SoC), state of health (SoH) and state of function

Get Price

The Ultimate Guide to Lead Acid Battery BMS: Everything You

This article looks into the fundamentals of lead-acid battery BMS, including its components, functioning, importance and benefits, problems, developments, maintenance,

Get Price

Do Lead Acid Batteries Need A Battery Management System?

A lead-acid battery contains sulfuric acid and lead, both hazardous materials. A BMS can monitor for events like leaks, internal shorts, and other safety issues, provide early

Get Price

1X HA01 Battery Voltage Equalizer

1X HA01 battery equalizer is an energy transfer equalizer that can compensate for batteries in both directions. Thi sis manufactured by the Heltec.

Get Price

The Ultimate Guide to Lead Acid Battery BMS:

This article looks into the fundamentals of lead-acid battery BMS, including its components, functioning, importance and benefits, problems,

Get Price

Lead-Acid Battery Management Systems: A Key to Optimal...

Lead-acid batteries have been a workhorse in various applications, providing reliable power for decades. However, to ensure their optimal performance and longevity, the implementation of

Get Price

Battery Chemistry Comparison, Capacity, Efficiency and BMS

A lead-acid battery contains sulfuric acid and lead, both hazardous materials. A BMS can monitor for events like leaks, internal shorts, and other

Get Price

Battery Chemistry Comparison, Capacity, Efficiency and BMS

The construction of a lead acid cell is one electrode is composed of lead and the other is lead dioxide. The electrolyte is sulfuric acid, which is converted to water during

Get Price

Lead-Acid Battery Management Systems: A Key to

Lead-acid batteries have been a workhorse in various applications, providing reliable power for decades. However, to ensure their optimal performance and

Get Price

Battery Basics

If you have researched how batteries work or what you should look for when selecting the best high-performance battery, you''re probably buried

Get Price

Electric Vehicle Battery Chemistry and

Battery chemistry and materials 1859: invention of the lead–acid battery (1st rechargeable battery) by French physicist Gaston Planté 1902: 1st "mass-produced" electric car (Studebaker

Get Price

Material Composition and Grid Structures in Lead-Acid Battery

The material composition and grid structure of lead-acid battery plates are crucial factors influencing their performance in starting and energy storage applications. Both types of

Get Price

1S, 2S, 3S, 4S BMS Circuit Diagram for Li-ion Batteries

In this guide, we will dive deep into BMS circuit diagram for 1S, 2S, 3S, and 4S Li-ion battery configurations, providing detailed explanations of its

Get Price

Lithium-Ion vs. Lead-Acid Batteries: How BMS Requirements

Lead-acid batteries, while more robust and cost-effective, require different management strategies to prevent sulfation and stratification. This post will explore these

Get Price

Lithium-Ion vs. Lead-Acid Batteries: How BMS Requirements

The core reason BMS requirements differ lies in the fundamental characteristics of each battery type. Lithium-ion batteries, known for their high energy density, are highly

Get Price

Lead-Acid Battery : Components, Reactions & Charging

Discover the science behind lead-acid batteries! Learn about their components, chemical reactions, rechargeable nature, and applications in vehicles & power systems.

Get Price

Overview of batteries and battery management for electric vehicles

Advances in EV batteries and battery management interrelate with government policies and user experiences closely. This article reviews the evolutions and challenges of (i)

Get Price

Battery Management System (BMS) | GERCHAMP

This article will explore the basic composition and working principles of the BMS structure and analyze its key role in battery management. Basic Composition of BMS Structure

Get Price

The Architecture of Battery Energy Storage Systems

The base cell of this battery is made with a negative lead electrode and a positive electrode made of bi-oxide or lead, while the

Get Price

Material Composition and Grid Structures in Lead-Acid Battery

The material composition and grid structure of lead-acid battery plates are crucial factors influencing their performance in starting and energy storage applications.

Get Price

The most complete analysis of bms for lead acid battery

The battery management system (BMS) quickly and reliably monitors the state of charge (SoC), state of health (SoH) and state of function (SoF) based on starting capability to provide the

Get Price

Lead-Acid Battery Management Systems

The BMS in lead-acid battery systems communicates with other smart grid components, providing data on battery status, SOC, temperature, and health.

Get Price

BMS for Lead Acid Battery

Find reliable bms for lead acid battery solutions. Durable, efficient, and versatile. Perfect for various applications. Shop now for top-notch performance!

Get Price

6 FAQs about [Composition of lead-acid battery BMS]

What is a lead acid battery BMS?

Lead-acid battery BMS has shown versatility and adaptability in a variety of applications, including renewable energy storage and electric forklifts. In conclusion, the Lead Acid Battery BMS is an important technology that improves the performance, safety, and durability of lead acid batteries in a variety of applications.

What is battery management system for lead acid batteries?

Battery Management System for Lead Acid Batteries is a one-of-a-kind solution that equalises two or more lead acid batteries in a battery bank linked in series, eliminating imbalance in the form of uneven voltage that occurs over time when charged and discharged in an inverter/UPS, etc.

Is lead acid a good battery chemistry?

Weight is a big concern to this battery chemistry as the energy density is one of the lowest of all the options at 90 Wh/L. However, lead acid is very cheap and typically does not require a battery management system (BMS) to monitor charge and discharge current unless the battery requires methods for fast charging techniques.

What is a lead acid battery balancing system?

In some systems, particularly those with large battery banks, active balancing is used to transfer energy from one cell to another in real-time, while passive balancing simply dissipates excess energy as heat. Implementing a Lead Acid BMS comes with numerous advantages, enhancing both performance and safety:

What makes a good BMS for lead-acid batteries?

Modern BMS for lead-acid batteries include the Active Equalisation Technique (AET), accomplished through a built-in microprocessor. AET technology lowers the frequency of battery water topping and other maintenance expenditures. A decent BMS also provides some additional distinctive features, as mentioned below.

What are the main functions of a lead-acid battery (BMS)?

The main functions of a lead-acid battery (BMS) are Track the battery’s state of charge (SOC), voltage, current, temperature, and other metrics. Keep the battery from running beyond its safe operating range. Balance the cells in the battery pack so that they all have the same voltage.

More related information

-

The function and composition of battery management system BMS

The function and composition of battery management system BMS

-

Composition of Uzbekistan BMS battery management control system

Composition of Uzbekistan BMS battery management control system

-

Somaliland BMS lithium battery composition

Somaliland BMS lithium battery composition

-

Battery battery pack BMS difference

Battery battery pack BMS difference

-

Serbia outdoor battery cabinet bms merchant

Serbia outdoor battery cabinet bms merchant

-

Bms new energy battery

Bms new energy battery

-

San Marino lithium iron phosphate BMS battery

San Marino lithium iron phosphate BMS battery

-

Is there a BMS battery management system

Is there a BMS battery management system

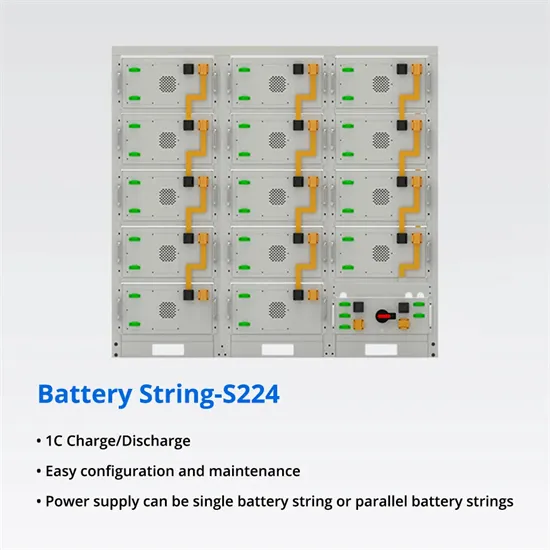

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.