What does lithium battery string mean

The ternary lithium battery standard specifies a voltage of 3.7v, full of 4.2v, three strings are 12v, 48v requires four three strings, but the electric vehicle lead-acid battery is fully charged with 58v.

Get Price

How many strings are commonly used for energy storage battery

Battery strings refer to the way batteries are interconnected within the pack. The three primary configurations—series, parallel, and hybrid—affect charging parameters, energy

Get Price

How to Balance Lithium Batteries with Parallel BMS?

Parallel Cells vs. Strings in Parallel When designing a lithium battery pack, engineers have two primary options: connecting individual cells

Get Price

How many strings are there of 12v lithium battery packs

The ternary lithium battery standard specifies a voltage of 3.7v, full of 4.2v, three strings are 12v, 48v requires four three strings, but the electric vehicle lead-acid battery is fully

Get Price

The LiFePO4 (LFP) Battery: An Essential Guide

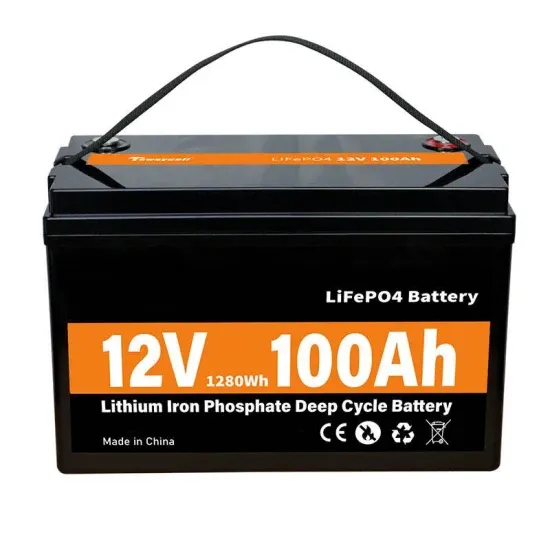

A 12-volt battery for example is typically composed of four prismatic battery cells. Lithium ions move from the negative electrode through

Get Price

solar string panel replacement

Solar Battery Box Kit Pack Powered Lithium Panel Light with Remote Control for Led String Strip Lamp 24V DIY US $10.41 US $14.07 -26%

Get Price

12V Lithium Ion Battery Guide, 12V Li Ion Battery

12V lithium battery is a lithium battery pack composed of 3 or 4 lithium batteries in series. The capacity of the battery is determined by the capacity of the single

Get Price

How many strings are 48V20AH lithium battery packs? How to

The ternary lithium battery standard specifies a voltage of 3.7v, full of 4.2v, three strings are 12v, 48v requires four three strings, but the electric vehicle lead-acid battery is fully

Get Price

How To Connect Batteries In Series and Parallel

We often get asked, "How do you create a higher-voltage battery pack?" The answer is you keep connecting batteries in series. For example,

Get Price

Battery Run Time Calculator

For example, if a device uses 2 Amperes at 12V: Power (W) = 12 × 2 = 24 W Which will run out first: a lithium-ion or a lithium (Li) battery?

Get Price

MPPT controller what is?? "12V/24V lead acid, 3 strings/6 strings

You need to wire at least three 30V solar panels in a series STRING to get the voltage high enough to charge a 48V battery. Since a 48V battery might be charged at as high

Get Price

What does the number of lithium battery strings represent

How many strings should a lithium battery have? Therefore, the lithium battery must also be about 58v, so it must be 14 strings to 58.8v, 14 times 4.2, and the iron-lithium full charge is about

Get Price

How many strings are there of 12v lithium battery packs

A 12V lithium battery pack generally requires 3 or 4 cells connected in series. The standard lithium-ion cell, such as the widely used 18650 type, has a nominal voltage of

Get Price

Make a 12 volt battery pack with three strings

Make a 12 volt rechargeable lithium battery pack Rechargeable lithium batteries produce 3.7 or 3.2 volts, depending on the type of battery and the chemicals it uses.

Get Price

How Many Cells in a Lithium Battery Pack? A Complete Guide to 12V

In summary, a standard 12V lithium battery pack typically consists of four cells in series. However, specific designs may vary based on performance needs and battery chemistry.

Get Price

Batteries & Chargers

This 3 Ah lithium-ion battery charges in 2 hours or less and can be used with a partial charge. The easy-view fuel gauge tells you exactly how much power remains before you need to grab

Get Price

BU-302: Series and Parallel Battery Configurations

While recommended for safety in a smaller 2- or 3-cell pack with serial and parallel configuration, these protection devices are often being omitted in

Get Price

Connecting batteries in parallel – BatteryGuy Knowledge Base

For example: two 6 volt 4.5 Ah batteries wired in parallel are capable of providing 6 volt 9 amp hours (4.5 Ah + 4.5 Ah). four 1.2 volt 2,000 mAh wired in parallel can provide 1.2

Get Price

12V Lithium Ion Battery Guide, 12V Li Ion Battery Pack

12V lithium battery is a lithium battery pack composed of 3 or 4 lithium batteries in series. The capacity of the battery is determined by the capacity of the single cell and the number of cells

Get Price

How many strings are commonly used for energy

Battery strings refer to the way batteries are interconnected within the pack. The three primary configurations—series, parallel, and

Get Price

12V-84V Lead-Acid 3-24 Strings Lithium Battery

This is 12V-84V Lead-Acid 3-24 Strings Lithium Battery Power Display Meter Power Display GY-6GS Green Self setting. The Battery Capacity Voltage

Get Price

How Many Cells in a Lithium Battery Pack? A Complete Guide to

In summary, a standard 12V lithium battery pack typically consists of four cells in series. However, specific designs may vary based on performance needs and battery chemistry.

Get Price

DIY 12v no Welding 4 String 18650 Lithium Battery Management

Amazon : DIY 12v no Welding 4 String 18650 Lithium Battery Management System BMS Protection Board Battery Box (4s4p Long) : Tools & Home Improvement3s: three

Get Price

Amazon : 12 Volt Battery Packs

Amazon : 12 volt battery packsTalentCell 12V 6Ah LiFePO4 Battery Pack, Ultra Long Life Cycles Rechargeable DC 12.8V 6000mAh 76.8Wh Lithium Iron Phosphate Backup Battery for

Get Price

BU-302: Series and Parallel Battery Configurations

While recommended for safety in a smaller 2- or 3-cell pack with serial and parallel configuration, these protection devices are often being omitted in larger multi-cell batteries, such as those for

Get Price

How many lithium cells for 12V?

To create a 12V lithium battery pack, you need four lithium cells connected in series. Each cell typically has a nominal voltage of 3.2V to 3.7V. This configuration allows the

Get Price

Strings, Parallel Cells, and Parallel Strings

Whenever possible, using a single string of lithium cells is usually the preferred configuration for a lithium ion battery pack as it is the lowest cost and simplest.

Get Price

Amazon : 12 Volt Lithium Battery Pack

TalentCell Rechargeable 12V 6000mAh/5V 12000mAh DC Output Lithium ion Battery Pack for LED Strip/CCTV Camera/Telescope/Modem and More, Portable Li-ion Power Bank with 12.6V

Get Price

6 FAQs about [Is the 12V lithium battery pack three or four strings ]

Can a lithium ion battery pack have multiple strings?

Whenever possible, using a single string of lithium cells is usually the preferred configuration for a lithium ion battery pack as it is the lowest cost and simplest. However, sometimes it may be necessary to use multiple strings of cells. Here are a few reasons that parallel strings may be necessary:

How many lithium batteries can be connected in series?

Lithium battery pack 48V20AH generally single lithium battery is 3.5V, so 48V lithium battery pack needs 48/3.5=13.7, just take 14 in series. If the manufacturer has provided a set of 12V lithium batteries, then 4 can be connected in series. As long as the output voltage is 48V, the current is 2A or 4A.

How many strings should a lithium battery have?

Therefore, the lithium battery must also be about 58v, so it must be 14 strings to 58.8v, 14 times 4.2, and the iron-lithium full charge is about 3.4v, it must be four strings of 12v, 48v must be 16 strings, and so on, 60v There must be 20 strings in parallel with the same model and the same capacity.

What is a 12V lithium battery pack?

Most commonly, a 12V lithium battery pack is made up of four lithium-ion cells, each with a nominal voltage of 3.7V. This configuration allows the pack to reach a total nominal voltage of approximately 14.8V when fully charged and around 12V when discharged.

How many cells are in a 12V battery pack?

Some packs may include additional cells for higher energy capacity or specific voltage requirements, but the standard configuration for a 12V battery is four cells. For example, a small electric vehicle or a solar power storage system commonly uses a 12V lithium battery pack with four cells.

What is a 12 volt battery?

It is essentially a measure of how long the battery can last before it needs to be recharged. When choosing lithium cells for a 12V battery, you need to consider both voltage and amp hours. To achieve 12 volts, you can either use multiple cells connected in series or choose lithium cells with higher nominal voltages (such as 3.7V).

More related information

-

Is the 12V lithium battery pack three or four strings

Is the 12V lithium battery pack three or four strings

-

Swiss 12v lithium battery pack

Swiss 12v lithium battery pack

-

12v lithium battery pack mobile power supply

12v lithium battery pack mobile power supply

-

Huijue American lithium battery pack 12v

Huijue American lithium battery pack 12v

-

How many strings are in a 48v 8ah lithium battery pack

How many strings are in a 48v 8ah lithium battery pack

-

24 lithium battery production 12v battery pack

24 lithium battery production 12v battery pack

-

South Sudan 12v lithium battery pack

South Sudan 12v lithium battery pack

-

60v lithium battery pack to 12v

60v lithium battery pack to 12v

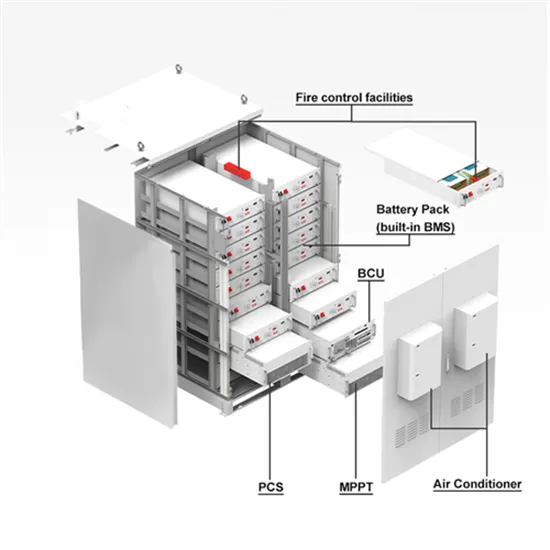

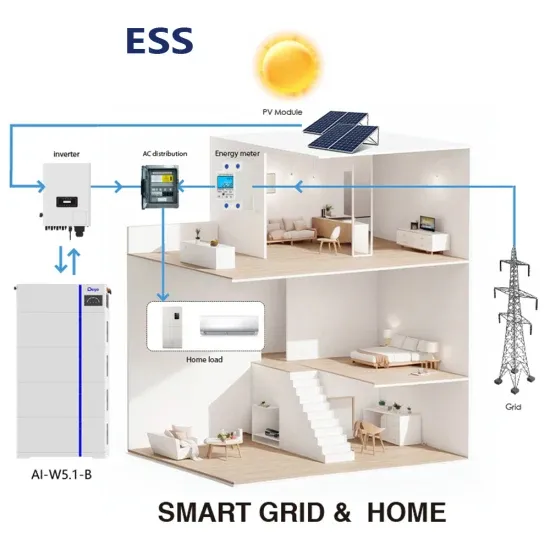

Commercial & Industrial Solar Storage Market Growth

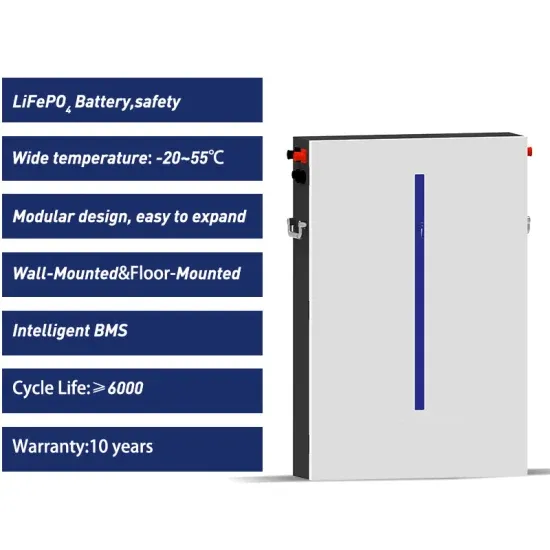

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.