Custom Lithium Battery Pack Manufacturing

In this comprehensive technical guide, I''ll share an in-depth look at our end-to-end custom lithium battery pack manufacturing process.

Get Price

Lithium batteries made in Brazil : Revista Pesquisa

Oxis Energy''s laboratory in England, where its lithium-sulfur battery technology was developed Oxis Energy A vehicle battery is an assembly of smaller

Get Price

China''s Anshan Heavy Duty to Build USD3.7 Billion Lithium

Anshan Heavy Duty has been actively hiking its battery raw materials capacity recently to meet surging demand from battery manufacturers. New lithium carbonate and

Get Price

Lithium Battery Pack Assembly: A Comprehensive

As the world transitions towards sustainable energy solutions, the demand for high-performance lithium battery packs continues to soar. At the

Get Price

China switches on its largest standalone battery

Located 41 kilometers east of Kashgar, Xinjiang, the project spans 119,000 square meters and represents a total investment of approximately

Get Price

Current and future lithium-ion battery manufacturing

INTRODUCTION Lithium-ion batteries (LIBs) have been widely used in portable electronics, electric vehicles, and grid storage due to their high energy density, high power density, and

Get Price

Lithium-ion Battery Safety

Lithium-ion Battery Safety Lithium-ion batteries are one type of rechargeable battery technology (other examples include sodium ion and solid state) that supplies power to many devices we

Get Price

California battery plant is among world''s largest as

The 680-megawatt lithium-ion battery bank is big even for California, which boasts about 55% of the nation''s power storage capacity,

Get Price

The Manufacturing Process of Lithium Batteries

Lithium battery manufacturing encompasses a wide range of processes that result in the production of efficient and reliable energy storage solutions. The

Get Price

LISHEN | LISEHN Battery | Lithium Battery | Li-ion Battery | EV Battery

The project order covers the replacement of lithium batteries for 550 12-meter electric buses, including battery production, commissioning and replacement services, which

Get Price

Lithium-ion cell and battery production processes

Lithium-ion battery cells are a technology that is categorized as a secondary energy storage system, the cells are uncharged after electrolyte filling. Forming is the process step in

Get Price

Best Project, Power/Industrial: Albemarle 50KT/A Lithium

This next-generation factory in China, owned by U.S.-based Albemarle Corp. to convert lithium ore into 50,000 tons per year of battery-grade lithium hydroxide for electric

Get Price

Zukunftsweisende Entscheidung: MAN baut Batteriefabrik in

Die Fertigungskapazitäten sollen auf über 100.000 Batterien pro Jahr ausgebaut werden. Durch die Investitionen in den Aufbau der Batterieproduktion werden perspektivisch 350

Get Price

Hithium''s 200 MWh Energy Storage Project Goes Live

Developed by China Resources Power Holdings, this plant marks the first commercial operation of its kind in Heze City, which has a population

Get Price

China switches on its largest standalone battery storage project

Located 41 kilometers east of Kashgar, Xinjiang, the project spans 119,000 square meters and represents a total investment of approximately CNY 1.6 billion ($222.9 million).

Get Price

About Us-Hithium

The company has built a 10GWh annual capacity battery module and energy storage system assembly plant in Mesquite, Texas, which is scheduled to be fully operational in July 2025.

Get Price

Hithium''s 200 MWh Energy Storage Project Goes Live in Heze City

Developed by China Resources Power Holdings, this plant marks the first commercial operation of its kind in Heze City, which has a population of nearly 8.3 million. The

Get Price

China''s Anshan Heavy Duty to Build USD3.7 Billion

Anshan Heavy Duty has been actively hiking its battery raw materials capacity recently to meet surging demand from battery

Get Price

What are the Laishan energy storage companies? | NenPower

Laishan''s geographical advantage —proximity to significant wind and solar farms—positions it as an ideal location for the development of energy storage technologies.

Get Price

LISHEN | LISEHN Battery | Lithium Battery | Li-ion Battery | EV

The project order covers the replacement of lithium batteries for 550 12-meter electric buses, including battery production, commissioning and replacement services, which

Get Price

Best Project, Power/Industrial: Albemarle 50KT/A

This next-generation factory in China, owned by U.S.-based Albemarle Corp. to convert lithium ore into 50,000 tons per year of battery

Get Price

Li-ion cell manufacturing: A look at processes and

The production of the lithium-ion battery cell consists of three main stages: electrode manufacturing, cell assembly, and cell finishing. Each of

Get Price

Stryten Energy Expands U.S. Battery Manufacturing

Stryten also recently opened a lithium battery assembly plant in Georgia that supports military and industrial battery needs with its proprietary

Get Price

About Us-Hithium

The company has built a 10GWh annual capacity battery module and energy storage system assembly plant in Mesquite, Texas, which is scheduled to be

Get Price

Reliance building largest battery plant in India

Reliance Industries has committed INR 75,000 crore (almost 9 billion USD) to establish an integrated manufacturing ecosystem for solar

Get Price

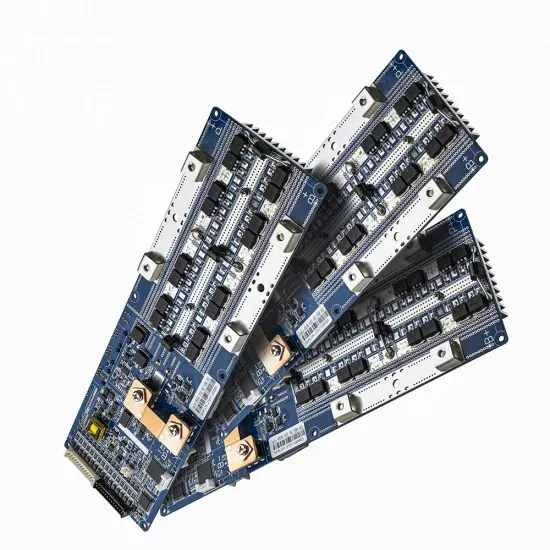

Battery Module: Manufacturing, Assembly and Test

In the Previous article, we saw the first three parts of the Battery Pack Manufacturing process: Electrode Manufacturing, Cell Assembly, Cell

Get Price

Tsingshan to build $1.6 bln lithium battery plant in southern China

The project aims to meet demand for lithium-ion battery power and storage in southern China and contribute to China''s development of new energies, Tsingshan said.

Get Price

Stryten Plans to Add 10 GW of Battery Manufacturing Capacity

The company, which provides battery components to its factories, has plants in Pennsylvania, New York, Indiana, Missouri and Wisconsin. Stryten recently opened a lithium

Get Price

''World''s first'' large-scale semi-solid BESS

A 100MW/200MWh project using semi-solid batteries has been connected to the grid in Zhejiang, China, reportedly the world''s largest.

Get Price

More related information

-

Belize high voltage energy storage lithium battery assembly

Belize high voltage energy storage lithium battery assembly

-

Djibouti energy storage lithium battery assembly manufacturer

Djibouti energy storage lithium battery assembly manufacturer

-

Indian energy storage battery assembly plant

Indian energy storage battery assembly plant

-

Energy Storage Battery Cabinet Assembly Cost Site

Energy Storage Battery Cabinet Assembly Cost Site

-

Greek lithium battery energy storage battery brand

Greek lithium battery energy storage battery brand

-

Lithium iron phosphate titanate battery energy storage

Lithium iron phosphate titanate battery energy storage

-

Lead Battery and Lithium Battery Energy Storage

Lead Battery and Lithium Battery Energy Storage

-

Guyana energy storage lithium battery price

Guyana energy storage lithium battery price

Commercial & Industrial Solar Storage Market Growth

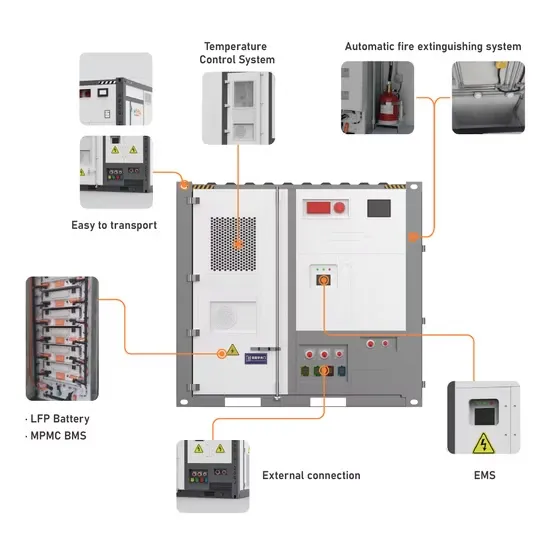

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.