Power Inverter Basics

High input voltages like 100000V DC or higher are used for inverters used in high voltage DC power transmission stations / lines. What is

Get Price

section 1_7 Digital Inverters.pdf

It says to avoid the transition region (i.e., for the input voltage to have an unambiguously "low" digital level), the noise must be less than noise margin NML for all time t !

Get Price

A comprehensive guide to inverter voltage

The input voltage is the DC voltage that the inverter receives from an external power source. The external power source can come from a variety of sources, including

Get Price

What Is Inverter Voltage?

The input voltage 1 of an inverter refers to the voltage level at which it receives energy. This is typically DC (direct current) power coming from a battery or solar panel system.

Get Price

How to Read Solar Inverter Specifications

The maximum DC input voltage is all about the peak voltage the inverter can handle from the connected panels. The value resonates with the safety limit for the inverter.

Get Price

Power inverter

A typical power inverter device or circuit requires a stable DC power source capable of supplying enough current for the intended power demands of the

Get Price

Solar Integration: Inverters and Grid Services Basics

Fundamentally, an inverter accomplishes the DC-to-AC conversion by switching the direction of a DC input back and forth very rapidly. As a result, a DC input

Get Price

Inverter input voltage: what it means, choosing the right one

Solar inverter input voltage is the voltage that the solar inverter receives from any source; either energy generating source or energy storing source. That means that inverter

Get Price

Definition of Inverter Specifications

Maximum DC Power (W). This indicates the maximum DC power input to the inverter. Maximum Input Short Circuit Current DC (A). This indicates the maximum short circuit current that can

Get Price

Power inverter

A typical power inverter device or circuit requires a stable DC power source capable of supplying enough current for the intended power demands of the system. The input voltage depends on

Get Price

Understanding Inverter Input and Output: What is the Relationship

Input Voltage: The input voltage supplied from the DC source to the inverter follows the inverter voltage specifications, which start from 12V, 24V, or 48V. Input Current: determines the

Get Price

What is an inverter? | inverter

The input interface includes 3 signals, 12V DC input VIN, working enabling voltage ENB and Panel current control signal DIM. Among them, VIN is provided by adapter, and ENB

Get Price

A Guide to Solar Inverters: How They Work & How to

Learn what a solar inverter is, how it works, how different types stack up, and how to choose which kind of inverter for your solar project.

Get Price

Understanding Inverter Ratings and Specifications for Solar Power

Input Voltage Range: Matching Solar Panels The input voltage range of an inverter determines the range of DC voltages that it can accept from the solar panels. Proper matching of the

Get Price

What is equation for inverter output voltage?

I am confused to select the value of DC input to have some specific value of output voltage. Please suggest possible solution or voltage equation for inverters.

Get Price

Understanding inverter voltage

The start inverter voltage is the minimum input voltage required for the inverter to initiate the conversion process. In the case of a 12V inverter, the start inverter voltage is

Get Price

Inverter Voltage Calculator

The difference in modulation indices affects the inverter voltage by determining the ratio of the output voltage to the input DC bus voltage. A higher modulation index difference

Get Price

Hybrid Inverters: Input vs. Charge Current Guide

For example, a hybrid inverter may support an 80A charge current, charging a battery at up to 80A based on its voltage. How MPPT Works: MPPT

Get Price

What does the inverter voltage specifications represent?

Since grid voltage fluctuates constantly, the inverter has to adjust to that voltage within a given window. For instance, the Xantrex GT5.0 can be installed as a 240v or a 208v inverter, but it

Get Price

Understanding Inverter Input and Output: What is the

Input Voltage: The input voltage supplied from the DC source to the inverter follows the inverter voltage specifications, which start from 12V, 24V,

Get Price

A comprehensive guide to inverter voltage

The input voltage is the DC voltage that the inverter receives from an external power source. The external power source can come from a variety

Get Price

Interpreting inverter datasheet and main parameters | AE 868

Both the maximum voltage value and operating voltage range of an inverter are two main parameters that should be taken into account when stringing the inverter and PV array. PV

Get Price

Explaining Solar Inverter Datasheets: A

As the world shifts towards clean energy sources, solar power is becoming increasingly popular. A solar inverter

Get Price

Inverter Specifications and Data Sheet

The article provides an overview of inverter functions, key specifications, and common features found in inverter systems, along with an example of power calculations and inverter

Get Price

PV Array Voltage and Size: What You Need to Know

Once you have your max module voltage, all you need is the max voltage input for your inverter. Typically, you can find this on the inverter''s datasheet. From here, divide your inverter''s max

Get Price

Inverter Specifications and Data Sheet

Solar inverter input voltage is the voltage that the solar inverter receives from any source; either energy generating source or energy storing source. That means that inverter

Get Price

6 FAQs about [What is the inverter input voltage]

What do you need to know about input power inverters?

Here are some important specifications that you need to know about input power inverters. Input Voltage: The input voltage supplied from the DC source to the inverter follows the inverter voltage specifications, which start from 12V, 24V, or 48V.

What is the input voltage of an inverter?

Understanding the inverter voltage is crucial for selecting the right equipment for your power system. Inverter voltage typically falls into three main categories: 12V, 24V, and 48V. These values signify the nominal direct current (DC) input voltage required for the inverter to function optimally. What is the rated input voltage of an inverter?

What is inverter output?

The inverter output is the electrical power generated by the inverter from the process of converting the DC input source into alternating current (AC).

What are the input specifications of a solar inverter?

The input specifications of an inverter concern the DC power originating from the solar panels and how effectively the inverter can handle it. The maximum DC input voltage is all about the peak voltage the inverter can handle from the connected panels. The value resonates with the safety limit for the inverter.

What is the maximum input voltage for a 12V inverter?

The maximum input voltage for an inverter is a critical specification that ensures the device operates within safe limits. For a 12V inverter, the maximum input inverter voltage is typically around 16VDC. This safety margin provides a buffer to accommodate fluctuations in the power source and protect the inverter from potential damage.

What is the AC output voltage of a power inverter?

The AC output voltage of a power inverter is often regulated to be the same as the grid line voltage, typically 120 or 240 VAC at the distribution level, even when there are changes in the load that the inverter is driving. This allows the inverter to power numerous devices designed for standard line power.

More related information

-

What is the input voltage range of the 48v inverter

What is the input voltage range of the 48v inverter

-

What is the inverter input voltage

What is the inverter input voltage

-

What is the normal output voltage of the inverter

What is the normal output voltage of the inverter

-

Inverter input voltage DC12DC24

Inverter input voltage DC12DC24

-

What is a new energy high voltage inverter

What is a new energy high voltage inverter

-

72V inverter changing input voltage

72V inverter changing input voltage

-

What is the inverter discharge protection voltage

What is the inverter discharge protection voltage

-

Judge the inverter input voltage

Judge the inverter input voltage

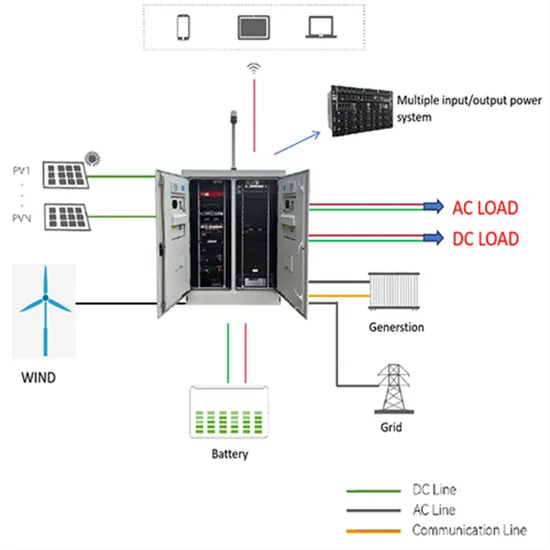

Commercial & Industrial Solar Storage Market Growth

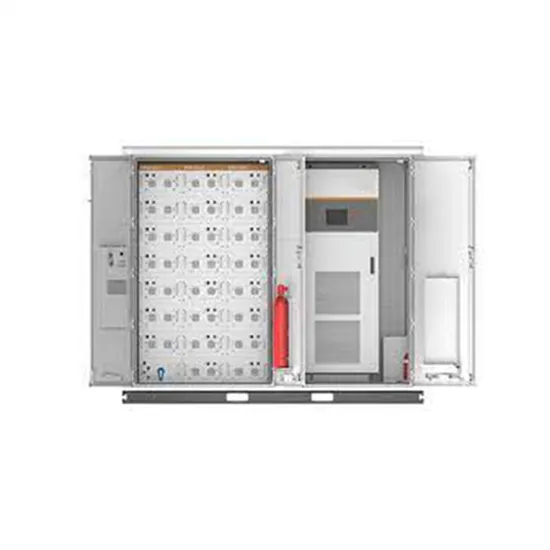

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

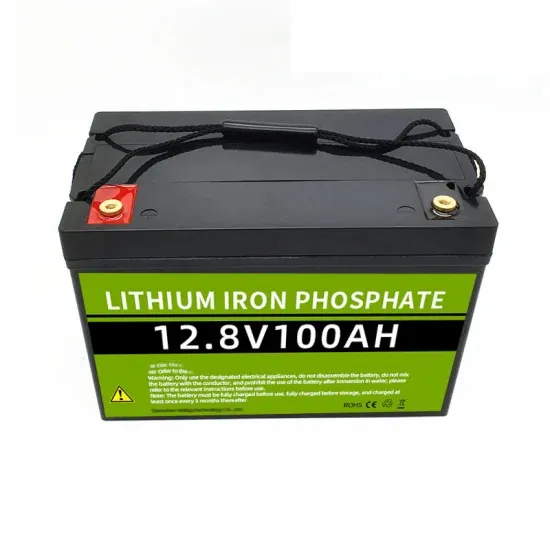

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.