What is a solar integrated machine? | NenPower

A solar integrated machine represents a technological innovation that combines photovoltaic power generation with operational mechanisms

Get Price

Solar Photovoltaic Manufacturing Basics

Solar manufacturing encompasses the production of products and materials across the solar value chain. This page provides background information on

Get Price

Solar photovoltaic panel production in Mexico: A novel machine

This study examines the potential for widespread solar photovoltaic panel production in Mexico and emphasizes the country''s unique qualities that position it as a strong

Get Price

The Role of Machinery in PV Production | Eco Green Energy

In this article, we''ll explore the key machines driving PV module production, their roles in the process, and how they are shaping trends in the solar industry.

Get Price

The Production and Manufacturing Process of Photovoltaic Modules

Photovoltaics are divided into four stages: silicon material, silicon wafers, solar cells, and modules. Photovoltaic modules are the downstream segment in the photovoltaic industry

Get Price

The Role of Machinery in PV Production | Eco Green

How the Right Solar Panel Making Machines are Shaping PV Efficiency P hotovoltaic (PV) production is an intricate process where machinery is KEY in

Get Price

Solar Panel (Module) Production Line

We provide solar panel production line, full automatic conveyor with full automatic laminator, full automatic tabber stringer and full automatic panel tester.

Get Price

Solar Photovoltaic Panel Production Line Assembly

Here is a detailed introduction to the types, structure, characteristics, automated assembly production process, and production line equipment of photovoltaic modules:

Get Price

Solar panel production equipment and machinery

Discover the latest Solar panels'' production & testing machines from Ecoprogetti Srl by clicking here. Solar panel production equipment and machinery. Nowadays the solar

Get Price

Solar Hybrid Inverter 2400w/4000w Pure Sine Wave

This item: Solar Hybrid Inverter 2400w/4000w Pure Sine Wave Inverter,Mppt 50A Photovoltaic Controller Inverter Control Integrated Machine,Off Grid 24V/48V Battery Charger Solar

Get Price

Machine learning in photovoltaic systems: A review

The total produced power by a PV system is influenced primarily by two elements: the solar irradiance and the cell temperature of the solar panel arrays. To consistently obtain

Get Price

Solar Panel Making Machines: A Guide to the

In this comprehensive guide, you will discover a fundamental overview of solar panel making machines and production processes essential

Get Price

Automatic corner chamfering machine for solar panels

The ECO GRINDING machine is an automatic, inline solution designed specifically for smoothing and chamfering the corners of solar panel frames. This essential process not only eliminates

Get Price

SOLAR/PV EQUIPMENT – Semiphoton

To improve production efficiency, our Solar/PV modules production line is equipped with intelligent MES and defects detection systems: EL-VI, Hi-Pot, IV, Calibration, and other testers.

Get Price

What is a solar integrated machine? | NenPower

Factories and warehouses implement solar integrated machinery to operate heavy equipment powered by sunlight, thus reducing their reliance on fossil fuels. This strategy not

Get Price

Why an Automatic Bussing Machine is Key for Solar

Explore automatic bussing machines for solar panel manufacturing. Learn about key features, benefits, and drawbacks to boost

Get Price

Solar Photovoltaic Panel Production Line Assembly

Here is a detailed introduction to the types, structure, characteristics, automated assembly production process, and production line equipment of photovoltaic

Get Price

What is a solar integrated machine? | NenPower

Factories and warehouses implement solar integrated machinery to operate heavy equipment powered by sunlight, thus reducing their reliance

Get Price

Solar Panel (Module) Production Line

We provide solar panel production line, full automatic conveyor with full automatic laminator, full automatic tabber stringer and full automatic panel tester. Professional solar panel making

Get Price

PV Solar Cell Manufacturing Process & Equipment Explained

Explore the solar module manufacturing process in detail and discover how Smartech''s solutions enhance efficiency in PV cell production.

Get Price

Solar Photovoltaic Panel Production Line Assembly

The photovoltaic panel production line is a highly automated manufacturing process that involves precise testing, classification, welding, and interconnection of solar cells, as well as the

Get Price

Bettsun 8KW 48V Hybrid Solar Inverter with Dual MPPT

This 8KW 48V inverter seamlessly integrates grid-tied, off-grid, and hybrid modes, offering maximum versatility for users with different power needs. It ensures continuous and reliable

Get Price

Abloomax-Solar Panel Making Machines

Abloomax LLC, based in Bothell, Washington, USA, is the American branch of REOO Technology Co., Ltd. from China.We specialize in designing,

Get Price

Solar Panel Production Process: A Complete Guide

1. Purpose How are solar panels made? This document gives guidelines on the solar panel production process. It also gives details of the relevant raw

Get Price

The Role of Machinery in PV Production | Eco Green

In this article, we''ll explore the key machines driving PV module production, their roles in the process, and how they are shaping trends in the solar industry.

Get Price

Solar Panel Making Machine Supplier | ConfirmWare

ConfirmWare Solar Panel Making Machines ConfirmWare is a leading and trusted provider of automatic machinery for solar panel production lines for local and

Get Price

Solar Panel Making Machines: A Guide to the Production

In this comprehensive guide, you will discover a fundamental overview of solar panel making machines and production processes essential for understanding solar panel

Get Price

PV Solar Cell Manufacturing Process & Equipment

Explore the solar module manufacturing process in detail and discover how Smartech''s solutions enhance efficiency in PV cell production.

Get Price

Solar Panel Production Line Provider | ConfirmWare

Full Processes of Solar Panel Manufacturing Our turnkey PV module production lines are designed to reduce your footprints, with customizable all-in-one functions turning solar cells to

Get Price

China All-In-One Energy Storage Manufacturers,

ONESUN Technology (Shenzhen) Ltd.: Find professional all-in-one energy storage, battery, PV inverter, PV accessories, solar panel manufacturers and

Get Price

Solar Photovoltaic Manufacturing Basics

Solar manufacturing encompasses the production of products and materials across the solar value chain. This page provides background information on several manufacturing processes

Get Price

6 FAQs about [48v photovoltaic solar panel production solar integrated machine]

What is P hotovoltaic (PV) production?

P hotovoltaic (PV) production is an intricate process where machinery is KEY in ensuring high-quality, efficient, and cost-effective solar panels. In this article, we’ll explore the key machines driving PV module production, their roles in the process, and how they are shaping trends in the solar industry.

Where can I find the latest solar panels production & testing machines?

Discover the latest Solar panels’ production & testing machines from Ecoprogetti Srl by clicking here. Solar panel production equipment and machinery Nowadays the solar panels’ production equipment is divided into the following required machinery and accessories.

How are solar panels manufactured?

Nowadays the solar panels’ production equipment is divided into the following required machinery and accessories. The first run automated processes are the stringing and lamination, but also the analysis of quality as electroluminescence tests. These and other procedures are indispensable for the correct manufacture of the module in each component.

How does solar manufacturing work?

How Does Solar Work? Solar manufacturing encompasses the production of products and materials across the solar value chain. While some concentrating solar-thermal manufacturing exists, most solar manufacturing in the United States is related to photovoltaic (PV) systems.

What are the key trends shaping the machinery in PV module production?

Here are the key trends shaping the machinery in PV module production: Automation has revolutionized solar production. Robotic arms and automated handling systems are now used extensively to handle delicate materials like silicon wafers and solar cells. This reduces human error, increases production speed, and ensures consistency across modules.

How are PV solar cells made?

The manufacturing process of PV solar cells necessitates specialized equipment, each contributing significantly to the final product’s quality and efficiency: Silicon Ingot and Wafer Manufacturing Tools: These transform raw silicon into crystalline ingots and then slice them into thin wafers, forming the substrate of the solar cells.

More related information

-

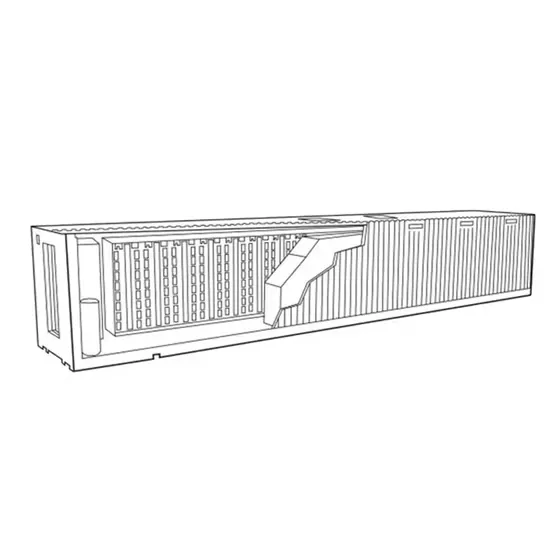

Split photovoltaic panel power generation solar integrated machine

Split photovoltaic panel power generation solar integrated machine

-

Photovoltaic solar panel production in Zambia

Photovoltaic solar panel production in Zambia

-

Photovoltaic solar panel production and wholesale

Photovoltaic solar panel production and wholesale

-

Can the integrated solar panel be equipped with more photovoltaic panels

Can the integrated solar panel be equipped with more photovoltaic panels

-

Photovoltaic energy storage solar integrated machine series

Photovoltaic energy storage solar integrated machine series

-

Vanuatu Solar Photovoltaic Panel Production Equipment Manufacturer

Vanuatu Solar Photovoltaic Panel Production Equipment Manufacturer

-

Selling solar photovoltaic panel production equipment standards

Selling solar photovoltaic panel production equipment standards

-

Solar panels connected to photovoltaic integrated machine

Solar panels connected to photovoltaic integrated machine

Commercial & Industrial Solar Storage Market Growth

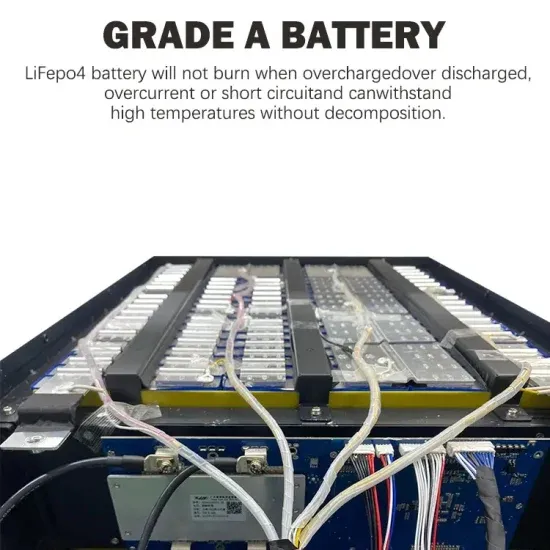

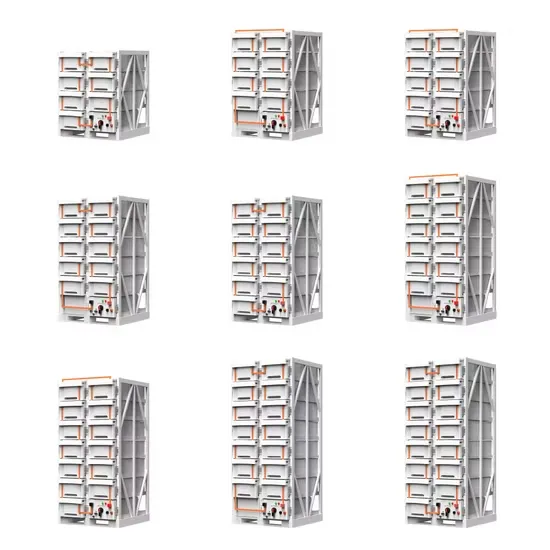

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.