Designing interphases for practical aqueous zinc flow

Aqueous zinc flow batteries (AZFBs) with high power density and high areal capacity are attractive, both in terms of cost and safety.

Get Price

Enlarging Zn deposition space via regulating Sn-induced effective

Zinc-based flow batteries (ZFBs) have aroused great favor in large-scale energy storage due to the high security and low cost. However, the low areal capacity arising from the

Get Price

Zinc-based hybrid flow batteries

Due to zinc''s low cost, abundance in nature, high capacity, and inherent stability in air and aqueous solutions, its employment as an anode in zinc-based flow batteries is

Get Price

A Neutral Zinc–Iron Flow Battery with Long Lifespan and High

Even at 100 mA cm –2, the battery showed an energy efficiency of over 80%. This paper provides a possible solution toward a low-cost and sustainable grid energy storage.

Get Price

Long-Term Performance of a Zinc–Silver/Air Hybrid

This work demonstrates an improved cell design of a zinc–silver/air hybrid flow battery with a two-electrode configuration intended

Get Price

Discharge profile of a zinc-air flow battery at various electrolyte

In flow batteries, the electrolyte is stored in external tanks and circulated through the cell. This study provides the requisite experimental data for parameter estimation as well

Get Price

Designing interphases for practical aqueous zinc flow batteries

Aqueous zinc flow batteries (AZFBs) with high power density and high areal capacity are attractive, both in terms of cost and safety.

Get Price

Perspectives on zinc-based flow batteries

Since the capacity of a zinc-based flow battery system is determined by the cell stack, not by the volume of the electrolyte, increasing the areal capacity is of utmost

Get Price

Long-Term Performance of a Zinc–Silver/Air Hybrid Flow Battery

This work demonstrates an improved cell design of a zinc–silver/air hybrid flow battery with a two-electrode configuration intended to extend the cycling lifetime with high

Get Price

Zn-Air Flow Batteries: One Step at a Time

Project Description: Development of advanced Zn –air flow batteries with high energy and power density. Motivation: Zn-air has high intrinsic theoretical energy density.

Get Price

Analysis of different types of flow batteries in energy

No matter what kind of zinc-iron flow battery, there are zinc dendrites and limited surface capacity on the anode side, which has become a

Get Price

Aqueous Zinc-Based Batteries: Active Materials,

Aqueous zinc-based batteries (AZBs) are emerging as a compelling candidate for large-scale energy storage systems due to their cost

Get Price

Balancing current density and electrolyte flow for improved zinc

We explore the interplay between current density, flow rate, and their influence on electrode surface morphology and the removal of the passivating zinc oxide layer to improve

Get Price

Liquid metal anode enables zinc-based flow batteries with

Here, we developed a liquid metal (LM) electrode that evolves the deposition/dissolution reaction of Zn into an alloying/dealloying process within the LM, thereby

Get Price

Compressed composite carbon felt as a negative electrode for a zinc

However, zinc-based flow batteries involve zinc deposition/dissolution, structure and configuration of the electrode significantly determine stability and performance of the battery.

Get Price

Advancing aqueous zinc and iron-based flow battery systems

Zinc-Bromine Flow Battery (collaboration with Redflow) 09-Sep-2022 Joined the ARC Hub 240 Ah, 10 kWh Electrode surface before (L) and after (R) operation

Get Price

Liquid metal anode enables zinc-based flow batteries

Here, we developed a liquid metal (LM) electrode that evolves the deposition/dissolution reaction of Zn into an alloying/dealloying process within

Get Price

Inhibition of Zinc Dendrites in Zinc-Based Flow Batteries

However, the formation of zinc dendrites at anodes has seriously depressed their cycling life, security, coulombic efficiency, and charging capacity. Inhibition of zinc dendrites is

Get Price

Recent developments in carbon‐based electrodes

Conversely, the HER interferes with Zn growth, resulting in a rough surface, heightened battery polarisation, and the formation of zinc dendrites.

Get Price

A zincophobic interface engineering achieving crystal-facet

Zinc-based flow batteries (ZFBs) have attracted considerable attention due to their high energy density, high safety, and low cost. However, the notorious dendrite problem is

Get Price

A Neutral Zinc–Iron Flow Battery with Long Lifespan

Even at 100 mA cm –2, the battery showed an energy efficiency of over 80%. This paper provides a possible solution toward a low-cost and

Get Price

Negatively charged nanoporous membrane for a

Here, we report a negatively charged nanoporous membrane for a dendrite-free alkaline zinc-based flow battery with long cycle life.

Get Price

Hydrogel electrolyte design for long-lifespan aqueous

A hydrogel electrolyte with reduced water content enables high-temperature aqueous zinc batteries by minimizing water activity and

Get Price

Discharge profile of a zinc-air flow battery at various electrolyte

Data Descriptor Open access Published: 22 June 2020 Discharge profile of a zinc-air flow battery at various electrolyte flow rates and discharge currents Ali asi, Soraya

Get Price

Zn-Air Flow Batteries: One Step at a Time

Motivation: Zn-air has high intrinsic theoretical energy density. Flow battery designs for Zn-air battery can allow higher performance, capacity. Technical Barriers Addressed: Need higher

Get Price

A zinc–iodine hybrid flow battery with enhanced energy storage capacity

Zinc–Iodine hybrid flow batteries are promising candidates for grid scale energy storage based on their near neutral electrolyte pH, relatively benign reactants, and an

Get Price

High current density charging of zinc-air flow batteries:

The surface morphology of electrodeposited zinc, as well as the formation and motion of bubbles, are evaluated using both in-situ and ex-situ microscopic imaging

Get Price

6 FAQs about [Zinc flow battery surface capacity]

Are aqueous zinc flow batteries safe?

Aqueous zinc flow batteries (AZFBs) with high power density and high areal capacity are attractive, both in terms of cost and safety. A number of fundamental challenges associated with out-of-plane

Are zinc-based flow batteries good for distributed energy storage?

Among the above-mentioned flow batteries, the zinc-based flow batteries that leverage the plating-stripping process of the zinc redox couples in the anode are very promising for distributed energy storage because of their attractive features of high safety, high energy density, and low cost .

How much does a zinc flow battery cost?

In addition to the energy density, the low cost of zinc-based flow batteries and electrolyte cost in particular provides them a very competitive capital cost. Taking the zinc-iron flow battery as an example, a capital cost of $95 per kWh can be achieved based on a 0.1 MW/0.8 MWh system that works at the current density of 100 mA cm-2 .

Are zinc-air flow batteries suitable for electrolyte storage?

In this regard, zinc-air flow batteries (ZAFBs) are seen as having the capability to fulfill this function. In flow batteries, the electrolyte is stored in external tanks and circulated through the cell. This study provides the requisite experimental data for parameter estimation as well as model validation of ZAFBs.

Can a zinc-based flow battery withstand corrosion?

Although the corrosion of zinc metal can be alleviated by using additives to form protective layers on the surface of zinc [14, 15], it cannot resolve this issue essentially, which has challenged the practical application of zinc-based flow batteries.

What are zinc-air flow batteries (zafbs)?

However, because of the intermittent nature of these energy sources, efficient energy storage systems are needed. In this regard, zinc-air flow batteries (ZAFBs) are seen as having the capability to fulfill this function. In flow batteries, the electrolyte is stored in external tanks and circulated through the cell.

More related information

-

How much liquid flow battery capacity does a communication base station have

How much liquid flow battery capacity does a communication base station have

-

Vanadium zinc flow battery

Vanadium zinc flow battery

-

Vanadium titanium flow battery investment

Vanadium titanium flow battery investment

-

Energy storage flow battery efficiency

Energy storage flow battery efficiency

-

Magnesium flow battery

Magnesium flow battery

-

Moroccan iron-chromium flow battery

Moroccan iron-chromium flow battery

-

Flow battery construction for communication base stations in Switzerland

Flow battery construction for communication base stations in Switzerland

-

Afghanistan Ministry of Foreign Affairs communication base station flow battery

Afghanistan Ministry of Foreign Affairs communication base station flow battery

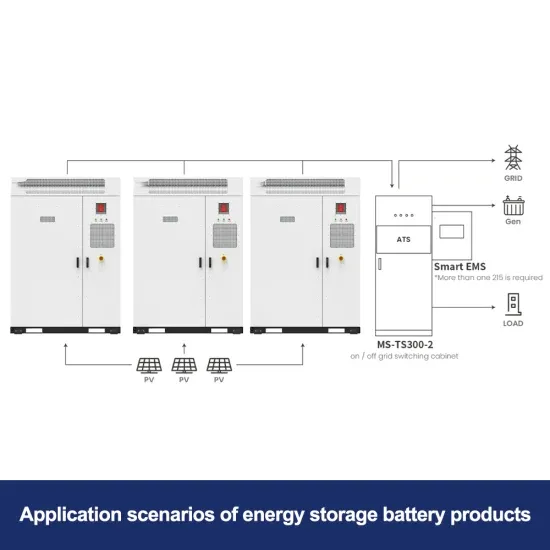

Commercial & Industrial Solar Storage Market Growth

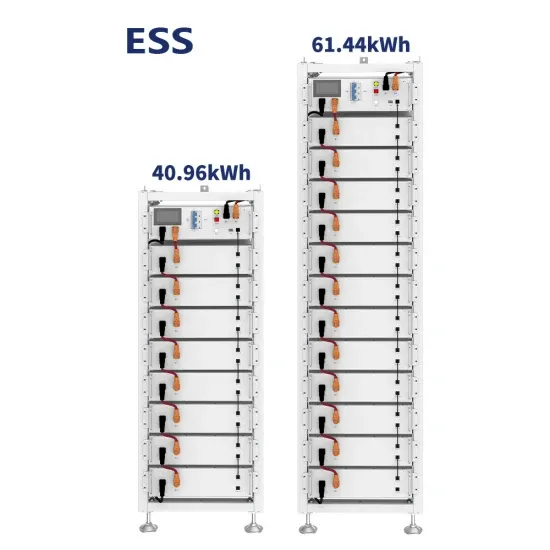

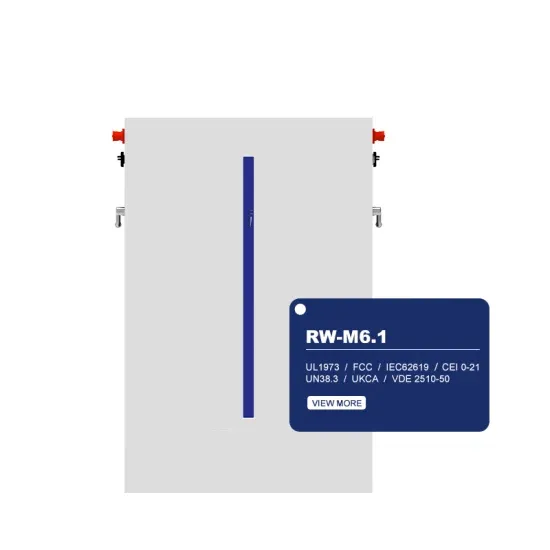

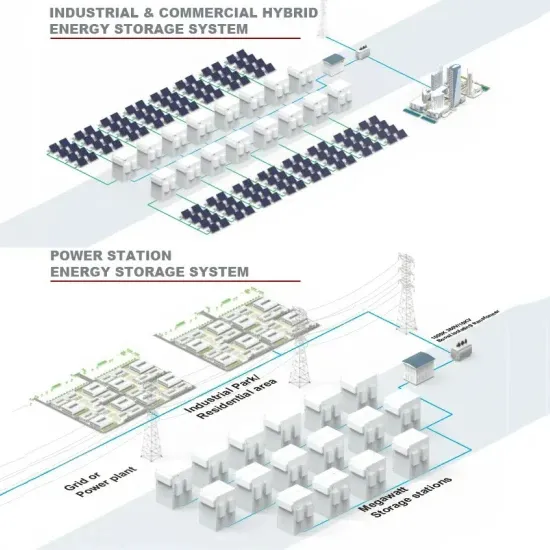

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.