What is the difference between a double-sided double-glass n

The difference between double-sided double-glass n-type monocrystalline solar photovoltaic module and ordinary components is reflected in multiple dimensions, from core

Get Price

What are the advantages of dual-glass Dualsun modules?

Double glass modules, due to the hermeticity of their structure, present less risk of PID. This phenomenon can be avoided by the use of an appropriate encapsulation material and by

Get Price

Flexible vs. Rigid Double-Glass Solar Panels: Which One is Your

Which is better, single-glass or double-glass solar panels? Overall, double-glass solar panels outperform single-glass panels in terms of efficiency, durability, and long-term returns, making

Get Price

What are Double Glass Solar Panels?

These are known as Double-Glass designs (solar panels with double glass or glass solar panels). The double glass module, as the name

Get Price

What are Double Glass Solar Panels?

Double-glass solar modules are made up of two layers of tempered glass that cover both sides of the solar panel. As snow accumulates on a typical solar panel or people

Get Price

Introduction of photovoltaic backsheet and

1. What is photovoltaic backsheet Photovoltaic backsheet is divided into inorganic backsheets, namely organic glass backsheets and polymer

Get Price

2025 Complete Guide to Glass-Glass Solar Panels:

A comprehensive analysis of the structural principles, performance advantages, and typical application scenarios of glass-glass PV modules, aligned with

Get Price

Photovoltaic installation of double glass components

What is a double glass c-Si PV module? Recently several double-glass (also called glass–glass or dual-glass modules) c-Si PV modules have been launched on the market, many of them by

Get Price

What are the differences between single-glass and double-glass

Whereas for Raytech double-glass solar modules, with the increased strength brought by two layers of glass, a lot less deformation will happen in the solar cells, the

Get Price

What are the differences between single-glass and

Whereas for Raytech double-glass solar modules, with the increased strength brought by two layers of glass, a lot less deformation will

Get Price

Single-glass and double-glass optical modules

Single-glass modules typically use a combination of glass, EVA (ethylene vinyl acetate) and a backsheet, while double-glass modules do not require a backsheet and instead use a

Get Price

**文件名称

Fire resistance of Suntech''s bifacial and double glass module is Class C according to IEC61730-2, and is suitable for mounting over a class A roof. Do not install modules on a roof or building

Get Price

What are Double Glass Solar Panels?

The difference between double-sided double-glass n-type monocrystalline solar photovoltaic module and ordinary components is reflected in multiple dimensions, from core

Get Price

Bifacial solar panels: Benefits & Installation Scenarios

This blog post will give you an in-depth understanding of bifacial solar panels, a disruptive solar technology. We will introduce what a bifacial solar panel is and

Get Price

Single-glass versus double-glass: a deep dive into module

Double-glass modules, with their performance in the face of salt mist, high temperatures and high humidity, have won the market''s favour. However, this trend is not

Get Price

Double glass solar module | Maysun Solar

As a result, double glass modules are especially suitable for use in islands, at high altitudes, and in extreme climatic regions. If you''re looking for an efficient and stable photovoltaic solution

Get Price

Do BIPV solar panels support double-glass design?

6. Examples of scenarios suitable for using double-glass BIPV modules Office building glass curtain wall: Use double-glass BIPV to achieve both lighting and power

Get Price

Single-glass versus double-glass: a deep dive into module

Left: a double-glass module; right, a bifacial single-glass module. The wave of industrial consolidation is growing ever more pronounced, shaping the landscape with each

Get Price

N-TopCon Series Solar Module Manufacturer/Supplier

TOPCon Solar Module (N-Type) TOPCon solar cells utilize advanced Tunnel Oxide Passivated Contact (TOPCon) technology, which is developed based

Get Price

Double the strengths, double the benefits

While double glass modules offer numerous benefits, it''s essential to consider factors such as weight and installation requirements.

Get Price

2025 Guide to Dual-Glass Solar Modules: When Premium Panels

Dual-glass solar modules represent a premium technology solution designed for demanding conditions where conventional panels may struggle.

Get Price

Flexible vs. Rigid Double-Glass Solar Panels: Which

Which is better, single-glass or double-glass solar panels? Overall, double-glass solar panels outperform single-glass panels in terms of efficiency, durability,

Get Price

Double the strengths, double the benefits

While double glass modules offer numerous benefits, it''s essential to consider factors such as weight and installation requirements. Advancements in manufacturing have led

Get Price

Double glass solar module | Maysun Solar

As a result, double glass modules are especially suitable for use in islands, at high altitudes, and in extreme climatic regions. If you''re looking for an efficient

Get Price

Transparent backplane and double-glass solar panels:

Double-glass modules are known for their excellent water resistance. The transparent backplane module uses a double-sided fluorinated backplane and POE packaging

Get Price

6 FAQs about [Is double-glass module suitable for distributed use ]

Why are double glass modules symmetrical?

Mechanical constraints on cells: the fact that the structure of the double glass modules is symmetrical implies that the cells are located on a so-called neutral line, the upper part of the module being in compression during a downward mechanical load and the lower glass surface being in tension.

Are double-glass solar modules reactive or non-reactive?

Furthermore, comparing to plastic backsheets (the back material of single-glass solar module) which are reactive, glass is non-reactive. This means that the whole structure of Raytech double-glass solar modules (two layers of glass and one layer of solar cells in the middle) are highly resistant to chemical reactions such as corrosion as a whole.

What is the difference between Raytech double glass solar modules?

Whereas for Raytech double-glass solar modules, with the increased strength brought by two layers of glass, a lot less deformation will happen in the solar cells, the possibility of microcracks formed on the solar cells will decrease significantly.

What is a dual-glass module?

Dual-glass type modules (also called double glass or glass-glass) are made up of two glass surfaces, on the front and on the rear with a thickness of 2.0 mm each. Some manufacturers, in order to reduce the weight of the modules, have opted for a thickness of 1.6 mm. DualSun has chosen to stay with a thickness of 2.0 mm for reasons explained below.

Are bifacial double-glass modules a good choice?

There has been a noteable shift from the initial single-facial single-glass modules to bifacial double-glass modules. Double-glass modules, with their performance in the face of salt mist, high temperatures and high humidity, have won the market’s favour. However, this trend is not without its risks.

What is double glass encapsulation?

Hermetic encapsulation: the double glass modules offer a hermetic structure, resistant to aggressive weather conditions, the main one being moisture penetration highlighted during tests so-called Damp Heat, according to standard IEC 61215-2: 2021 (clause MQT13).

More related information

-

Are photovoltaic panels suitable for home use

Are photovoltaic panels suitable for home use

-

Afghanistan double-glass photovoltaic module panels

Afghanistan double-glass photovoltaic module panels

-

Bifacial double-glass module power

Bifacial double-glass module power

-

Double-glass photovoltaic module subframe

Double-glass photovoltaic module subframe

-

Double-glass photovoltaic module design

Double-glass photovoltaic module design

-

Is the double-glass module monocrystalline or polycrystalline

Is the double-glass module monocrystalline or polycrystalline

-

Double-glass module market capacity

Double-glass module market capacity

-

Double-glass module market share

Double-glass module market share

Commercial & Industrial Solar Storage Market Growth

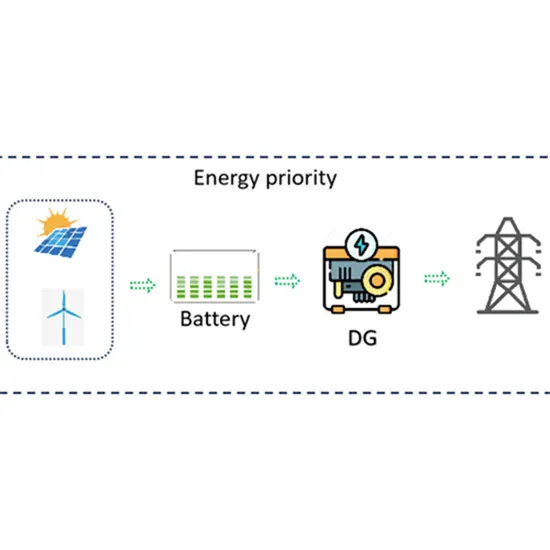

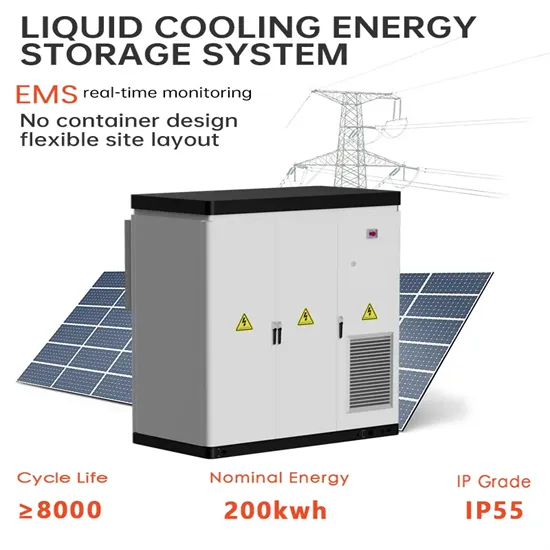

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.