The Design and Simulation of an Inverter

After you complete layout of the inverter, you need to draw "GRLOGIC" layer to enclose your inverter; this is to ensure your design is exempt from stringent design rule check

Get Price

Microsoft Word

Different topologies of traction inverters and power electronic components employed in battery-operated electric vehicles and hybrid electric vehicles at General Motors have been reviewed

Get Price

HEV/EV Traction Inverter Design Guide Using Isolated IGBT

The inverter design varies based on the power output requirements which depends on architecture. The proper control of the inverter directly impacts the motor''s efficiency and the

Get Price

How to Design an Inverter – Theory and Tutorial

In this post I have explained the fundamental tips and theories which may be useful for the newcomers while designing or dealing with basic inverter concepts. I have explained

Get Price

How to Design a SAFE, EFFICIENT, and COMPACT

In this comprehensive article, we will explore the key considerations and best practices for designing an inverter that meets these essential criteria.

Get Price

How to Design a SAFE, EFFICIENT, and COMPACT

In this comprehensive article, we will explore the key considerations and best practices for designing an inverter that meets these essential criteria. An

Get Price

Inverters: A Pivotal Role in PV Generated Electricity

Knobloch, A. et al: "Grid stabilizing control systems for battery storage in inverter-dominated island and public electricity grids", 13th ETG/GMA-Symposium on Energy Transition in Power

Get Price

Designing an Efficient Power Inverter Circuit

Learn how to build a power inverter circuit diagram to convert DC power into AC power for various applications. Step-by-step guide and circuit diagram.

Get Price

How to Design a SAFE, EFFICIENT, and COMPACT Inverter

In this comprehensive article, we will explore the key considerations and best practices for designing an inverter that meets these essential criteria. An inverter is a power electronic

Get Price

800VA Pure Sine Wave Inverter''s Reference Design

Power inverter is a device that converts electrical power from DC form to AC form using electronic circuits. It is typical application is to convert battery voltage into conventional household AC

Get Price

How to Design and Construct an Inverter System

Due to its efficiency and green house friendly, most people are switching from generator use to inverter use. Engineers, Electronics enthusiast, hobbyist and Technologist all over the globe

Get Price

Overview of power inverter topologies and control structures for

In grid-connected photovoltaic systems, a key consideration in the design and operation of inverters is how to achieve high efficiency with power output for different power

Get Price

What is a power inverter? | Tech | Matsusada Precision

Basic Technical Explanation of inverter - Power Inverter circuit and power inverter device, Frequency and Rotation Speed, Device configuration,

Get Price

Three-Phase Inverter Design | Tutorials on Electronics | Next

The most common three-phase inverter topology is the Voltage Source Inverter (VSI), where a fixed DC voltage is converted into a variable AC output. The VSI employs six power switches

Get Price

A technical review of modern traction inverter systems used in

This article presents a comprehensive review of modern traction inverter systems, their possible control strategies, and various modulation techniques

Get Price

Fundamentals of Electric Vehicle Powertrain Design

Description This NOS unit is about preparing for the fast evolving field of electric vehicle powertrain and its universal design for alternative fuel mobility. This NOS unit is about

Get Price

Designing the Perfect Solar Inverter: A Comprehensive Guide

Discover how to design the perfect solar inverter with our comprehensive guide. Learn about the components, features and benefits of a successful solar inverter system, as

Get Price

Inverter types and classification | AE 868: Commercial Solar

Before these strings are connected to the utility grid, a power conditioning unit is required as an interface between the array and the grid. Designers can use one central inverter as illustrated

Get Price

A short primer on traction inverter design for EVs

In many traction inverter designs, the key components are often separate and discretely packaged and, while this is a perfectly valid approach,

Get Price

Design and Construction of An Inverter | PDF | Power

This document outlines the design and construction of a DC-AC inverter. It begins with an introduction that defines an inverter and describes

Get Price

A High Frequency Variable Load Inverter Architecture

The inverter architecture consists of two constituent inverters, one connected directly through the load and the other connected through an immittance converter, which acts as a lossless power

Get Price

How to Design and Construct an Inverter System

Due to its efficiency and green house friendly, most people are switching from generator use to inverter use. Engineers, Electronics enthusiast, hobbyist and

Get Price

Design and Construction of An Inverter | PDF | Power Inverter

This document outlines the design and construction of a DC-AC inverter. It begins with an introduction that defines an inverter and describes its uses in powering small

Get Price

Optimal Structures for Voltage Controllers in Inverters

In this paper, we study the optimal structure of voltage controllers for ac inverter systems. In deriving the controller, we present a system-atic design framework for designing multivariable

Get Price

Three-Phase Inverter Design | Tutorials on Electronics | Next

1. Fundamentals of Three-Phase Inverters, 2. Components and Circuit Design, 3. Modulation Techniques for Three-Phase Inverters, 4. Control Strategies and Feedback Systems, 5.

Get Price

6 FAQs about [Inverter power unit structure design]

What is a power inverter?

All trademarks are the property of their respective owners. Power inverter is a device that converts electrical power from DC form to AC form using electronic circuits. It is typical application is to convert battery voltage into conventional household AC voltage allowing you to use electronic devices when an AC power is not available.

What are the components of a power inverter circuit diagram?

The main components of a power inverter circuit diagram include the battery, DC input, inverter circuit, transformer, output AC voltage, and protection circuits. The battery provides the DC power source, which is connected to the inverter circuit.

How to design a power inverter circuit?

When designing a power inverter circuit, it is important to consider the power requirements of the load that the circuit will be powering. The power rating of the inverter circuit and the transformer should be chosen accordingly to ensure that the circuit can handle the load’s power demands.

What does an inverter do?

An inverter is a power electronic device that converts direct current (DC) to alternating current (AC). The primary function of an inverter is to transform the voltage and current characteristics of the input DC power to match the requirements of the AC load.

How to design a high voltage inverter?

For higher voltage inverters this supply must be appropriately stepped down to 12V for the IC supply pins. From the above examples, it becomes quite evident that the most basic forms of inverters could be designed by simply coupling a BJT + transformer power stage with an oscillator stage.

What is a constituent inverter model?

The con-stituent inverter model that was created as part of the controller was modi ed to extract predicted e ciency data, loss breakdowns, and the load range of the proto-type before physical testing. e ciency of the prototype and collection of switching waveforms.

More related information

-

Power supply design of solar water pump inverter

Power supply design of solar water pump inverter

-

Photovoltaic power generation unit for communication base station inverter

Photovoltaic power generation unit for communication base station inverter

-

Design of single-phase inverter with output power of 6kva

Design of single-phase inverter with output power of 6kva

-

Photovoltaic panel power generation unit structure

Photovoltaic panel power generation unit structure

-

Huawei outdoor power supply structure design

Huawei outdoor power supply structure design

-

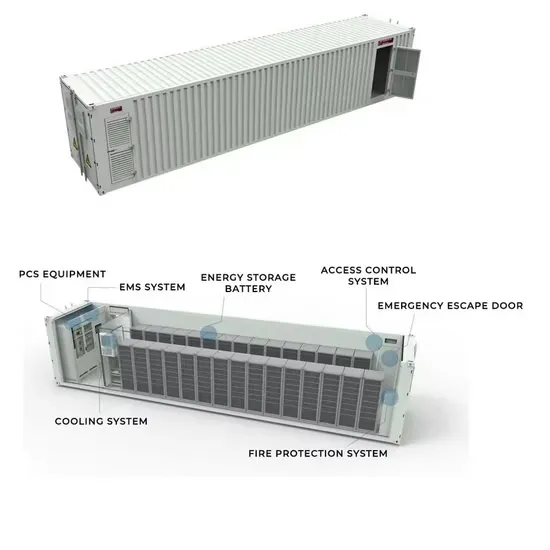

Energy Storage Power Station Planning and Design

Energy Storage Power Station Planning and Design

-

Pure sine wave inverter high power 12v to 220v

Pure sine wave inverter high power 12v to 220v

-

Inverter in photovoltaic power generation

Inverter in photovoltaic power generation

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.