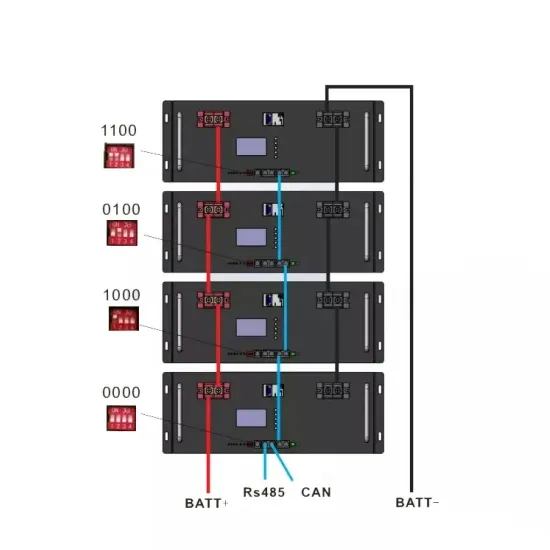

Lithium Series, Parallel and Series and Parallel

Lithium Series, Parallel and Series and Parallel Connections Introduction Lithium battery banks using batteries with built-in Battery Management Systems (BMS) are created by connecting

Get Price

Number of 18650 Cells Needed to Make A 12v Battery

Three 18650 cells are needed to make 12 volts in the most common configuration. In some cases, 4 cells can be used, but just not fully charged. Neither configuration is ideal

Get Price

how many 12v batteries are needed to power a house?

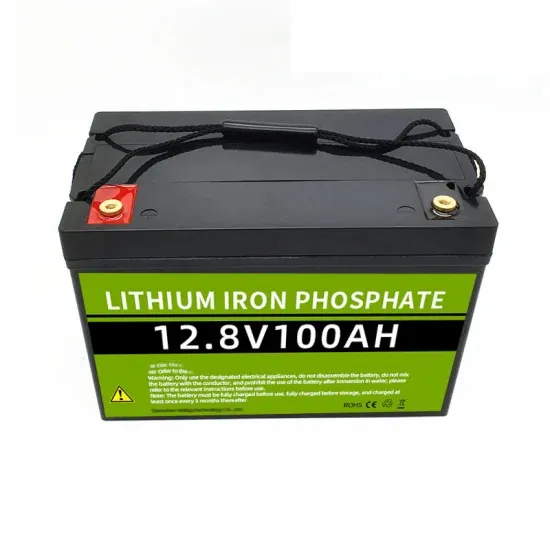

After estimating the daily power demand, you need to determine how many kilowatt-hours a 12V battery can provide, for example, a 12V 100Ah lithium iron phosphate

Get Price

How to Calculate the Number of Cells in a Battery

For example, let''s say we have a 12V battery with a capacity of 100Ah. We would divide 12 by 1.2 to get 10 cells. However, this is just an approximation – the actual number of

Get Price

18650 Battery Pack Calculator

To calculate an 18650 battery pack configuration: Determine required voltage: Divide target voltage by cell voltage (3.7V) to get cells in series. Calculate capacity needs: Divide desired

Get Price

Amazon : 12 Volt Lithium Ion Battery Pack

1-48 of over 10,000 results for "12 volt lithium ion battery pack" Results Check each product page for other buying options.

Get Price

How Many Lithium Cells Are Needed to Create a 12V Battery

How Many Lithium Cells Are Needed to Create a 12V Battery To create a 12V lithium battery, 3-4 lithium cells are typically connected in series. Lithium-ion cells have a

Get Price

How Many Lithium Cells Does It Take to Make a 12V Battery?

Configuration for 12V Batteries: To construct a 12V battery, we generally use 4 lithium cells in series. Each cell, providing around 3.7V, collectively produces the necessary

Get Price

Number of 18650 Cells Needed to Make A 12v Battery

Configuration for 12V Batteries: To construct a 12V battery, we generally use 4 lithium cells in series. Each cell, providing around 3.7V, collectively produces the necessary

Get Price

Lithium Battery Cartridge for REVEAL Trail Cameras

The REVEAL Lithium Cartridge can replace up to 1,000 AA batteries, keeping your camera on longer. This rechargeable pack can be charged through the

Get Price

Here is how to arrange the cells to make a battery

A 4S pack of LFP is the most common replacement for a 12V Lead-Acid battery pack (4P X 3.2V = 12.8V nominal). That being said, NCA/NCM in the 18650

Get Price

How Many Cells in a Lithium Battery Pack? A Complete Guide to

Most commonly, a 12V lithium battery pack is made up of four lithium-ion cells, each with a nominal voltage of 3.7V. This configuration allows the pack to reach a total

Get Price

Building 12V Battery Packs with 18650 Cells: A Guide

To build a 12V battery pack with 18650 cells, connect four cells in series (3.7V each) to achieve approximately 14.8V nominal. Use appropriate battery management systems (BMS)

Get Price

How Many Lithium Batteries Do I Need for a 36V Golf Cart? A

To power a 36V golf cart with lithium batteries, you typically need three 12V lithium batteries connected in series or a single 36V lithium battery if available. The choice depends

Get Price

Determine How Many Cells In A Battery Pack

You''re need to know the math behind building battery packs. I''ll demonstrate how to determine how many cells in a battery for your project.

Get Price

How many lithium cells in series are needed for a 12 V battery?

To create a 12V lithium battery, you typically need four lithium cells connected in series. Each lithium-ion cell has a nominal voltage of approximately 3.2 to 3.7 volts. By

Get Price

How Many Cells in a Lithium Battery Pack? A Complete Guide to 12V

Most commonly, a 12V lithium battery pack is made up of four lithium-ion cells, each with a nominal voltage of 3.7V. This configuration allows the pack to reach a total

Get Price

How Many Lithium Cells Are Needed to Build a 12V

In conclusion, the number of lithium cells required to build a 12V battery is typically 4, based on the nominal voltage of 3.7V per cell. However,

Get Price

How to Calculate the Number of Cells in a Battery

For example, let''s say we have a 12V battery with a capacity of 100Ah. We would divide 12 by 1.2 to get 10 cells. However, this is just an

Get Price

How Many Lithium Cells Are Needed to Build a 12V Battery

In conclusion, the number of lithium cells required to build a 12V battery is typically 4, based on the nominal voltage of 3.7V per cell. However, depending on your power needs,

Get Price

How many lithium cells for 12V?

To create a 12V lithium battery pack, you need four lithium cells connected in series. Each cell typically has a nominal voltage of 3.2V to 3.7V. This configuration allows the

Get Price

How Many Cells Are In A 12V LiFePO4 Battery Pack? A Guide To

How Many Cells Are Typically Found in a 12V LiFePO4 Battery Pack? A typical 12V LiFePO4 (Lithium Iron Phosphate) battery pack usually consists of 4 cells in series. Each

Get Price

What to Know Before Buying NiMH Battery Pack

Don''t buy NiMH battery packs without knowing these essential facts! Discover what to look for and make confident purchases now.

Get Price

Lithium (LiFePO4) Battery Runtime Calculator

Calculating battery runtime on a load can be confusing for some folks. We created a lithium battery runtime/life calculator for your ease.

Get Price

How Many Cells are in a 12V Lithium-Ion Battery?

Each cell typically provides around 3.7V, so to achieve a total of 12V, several cells need to be combined. The number of cells in a 12V battery can vary depending on the specific design and

Get Price

Building an 18650 battery pack! | EEPower

It''s generally not recommended to use 18650 cells to build a 12V battery, as they are typically designed for use in 3.7V or 3.6V lithium-ion battery packs. If you want to build a

Get Price

6 FAQs about [How many lithium battery packs are needed for 12v battery]

What is a 12V lithium battery pack?

Most commonly, a 12V lithium battery pack is made up of four lithium-ion cells, each with a nominal voltage of 3.7V. This configuration allows the pack to reach a total nominal voltage of approximately 14.8V when fully charged and around 12V when discharged.

How many cells are in a 12V battery pack?

Some packs may include additional cells for higher energy capacity or specific voltage requirements, but the standard configuration for a 12V battery is four cells. For example, a small electric vehicle or a solar power storage system commonly uses a 12V lithium battery pack with four cells.

How many cells are needed for a lithium battery?

To find the number of cells needed, divide the desired voltage by the voltage of a single cell. If a typical lithium cell operates at 3.7 volts, then for 48 volts, you would need 48V / 3.7V = approximately 13 cells in series. Assess capacity requirements: The capacity of cells is measured in ampere-hours (Ah).

How many volts can a lithium battery produce?

To achieve 12 volts, you can either use multiple cells connected in series or choose lithium cells with higher nominal voltages (such as 3.7V). For example, four lithium cells with a nominal voltage of 3.7V each would add up to 14.8 volts when connected in series.

How to calculate lithium cell count in a battery pack?

To calculate lithium cell count in a battery pack, use the formula: Total Voltage = Number of Cells x Nominal Voltage of Each Cell. 1. Understanding nominal voltage of lithium cells. 2. Identifying required total voltage for the application. 3. Considering parallel connections for capacity. 4.

What is a 12 volt battery?

It is essentially a measure of how long the battery can last before it needs to be recharged. When choosing lithium cells for a 12V battery, you need to consider both voltage and amp hours. To achieve 12 volts, you can either use multiple cells connected in series or choose lithium cells with higher nominal voltages (such as 3.7V).

More related information

-

How many 60v lithium battery packs are needed in Pakistan

How many 60v lithium battery packs are needed in Pakistan

-

How many strings of 24V lithium battery packs are needed

How many strings of 24V lithium battery packs are needed

-

How big an inverter should I use for a 12v 50A lithium battery

How big an inverter should I use for a 12v 50A lithium battery

-

How many lithium battery packs can be connected in parallel

How many lithium battery packs can be connected in parallel

-

How much does a 1100 degree 12v energy storage lithium iron phosphate battery cost

How much does a 1100 degree 12v energy storage lithium iron phosphate battery cost

-

How much is the lithium battery needed for 5G base stations worth

How much is the lithium battery needed for 5G base stations worth

-

How much electricity can a 12v 90A lithium battery store

How much electricity can a 12v 90A lithium battery store

-

5 sets of 12v lithium battery packs

5 sets of 12v lithium battery packs

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.