CHAPTER 2

2.2 Voltage Control in Single - Phase Inverters The schematic of inverter system is as shown in Figure 2.1, in which the battery or rectifier provides the dc supply to the inverter. The inverter is

Get Price

Inverter Power Calculator, Formula,Inverter Calculation

The inverter utilizes electronic circuits to convert the DC input voltage and current into AC output voltage and current. The AC output voltage and current are at the appropriate frequency (e.g.,

Get Price

Project design > Grid-connected system definition > Inverter / Array sizing

The inverter power sizing is a delicate and debated problem. Many inverter providers recommend (or require) a PNom array limit or a fixed Pnom (inverter / array) ratio, usually of the order of

Get Price

Solar inverters and clipping: What DC/AC inverter

The DC to AC ratio (also known as the Inverter Load Ratio, or "ILR") is an important parameter when designing a solar project. For example,

Get Price

Why is my PV Module rating larger than my Inverter rating?

The DC: AC ratio is the relationship between PV module power rating and inverter power. Every PV system has a DC:AC ratio regardless of architecture. Many inverters have DC:AC ratio

Get Price

Sharp® 1.1 Cu. Ft. Stainless Steel Flatbed Countertop Microwave

2 days ago· Product Overview The Sharp® SMC1174KS, Mid-Size, 1.1 cu. ft., 1100 Watt Flatbed Microwave Oven in Stainless Steel is exceptional when you want big value in small spaces!

Get Price

Understanding DC/AC Ratio

The only time the max AC of the inverter is important is if the DC power x efficiency is bigger than the max AC. In this case the maximum output produced is limited to the max AC power.

Get Price

EG4 FlexBOSS21 Inverter | 16kW | Hybrid | 48V

EG4 FlexBOSS21 16kW Inverter: 48V split-phase, 21kW PV input, 3 MPPTs, GridBOSS compatible, and supports remote monitoring.

Get Price

Hitachi Grid Tied Solar Inverters_Booklet 2.cdr

Hitachi Solar Inverter is a potent example, which being at the heart of Solar power generating system is bringing Social Innovation in the Indian power sector by providing the critical

Get Price

Understanding DC/AC Ratio

Because the PV array rarely produces power to its STC capacity, it is common practice and often economically advantageous to size the inverter to be less than the PV array. This ratio of PV

Get Price

Project design > Grid-connected system definition >

The inverter power sizing is a delicate and debated problem. Many inverter providers recommend (or require) a PNom array limit or a fixed Pnom (inverter

Get Price

Single Phase Half Bridge Inverter Explained

The output frequency of this type of inverter may be controlled by controlling the switch ON and switching OFF time of thyristors. Figure below

Get Price

AC-coupling and the Factor 1.0 rule

Frequency shifting is used to regulate the output power of a Grid-tie PV Inverter, or Grid-tie Wind inverter, by changing the frequency of the AC. The MultiPlus (or Quattro) will

Get Price

Solar inverters and clipping: What DC/AC inverter load ratio is

The DC to AC ratio (also known as the Inverter Load Ratio, or "ILR") is an important parameter when designing a solar project. For example, a 6-kW DC array combined

Get Price

Troubleshooting for 10-20kUE Three-Phase Inverter

If there are several inverters in parallel, and the inverter shows "AC V Outrange" after the inverter feed to grid working for a while, perhaps the grid impedance is too high, please record the AC

Get Price

What DC to AC inverter load ratio is ideal for your

The DC to AC inverter ratio (also known as the Inverter Load Ratio, or "ILR") is an important parameter when designing a solar project.

Get Price

What is an acceptable DC/AC ratio ? : r/solar

The only time the max AC of the inverter is important is if the DC power x efficiency is bigger than the max AC. In this case the maximum output produced is limited to

Get Price

Inverter Capacity Calculator

The result is the total power requirement, which should be less than or equal to the inverter''s capacity. What is an Inverter Capacity? Inverter

Get Price

SolarEdge Inverters, Power Control Options — Application Note

AC output power limit – limits the inverter''s output power to a certain percentage of its rated power with the range of 0 to 100 (% of nominal active power).

Get Price

Inverter Sizing-Determining The Perfect DC:AC Ratio!

The three pieces of information needed to determine the optimal balance are 1) the relationship between production output and the DC:AC ratio, 2) the cost of adding solar panel

Get Price

What DC to AC inverter load ratio is ideal for your application?

The DC to AC inverter ratio (also known as the Inverter Load Ratio, or "ILR") is an important parameter when designing a solar project.

Get Price

ESV112N02YXB Lenze AC Tech | VFD Drive Inverter

Buy Lenze VFD Drive Inverter ESV112N02YXB. 1.5 HP (1.1 kW) rated power, 240VAC 1 (3)/N Phase input, 6.0A @ 0-500 Hz output, NEMA Type 1,

Get Price

AC-coupling and the Factor 1.0 rule

Frequency shifting is used to regulate the output power of a Grid-tie PV Inverter, or Grid-tie Wind inverter, by changing the frequency of the AC.

Get Price

6 FAQs about [Inverter AC 1 1 times output]

Can an inverter output more than rated AC power?

Inverters will generally never output more than their max-rated AC power. During times when the DC input power is too high, the inverter will raise the operating voltage of the modules to pull the array off of its max power point and reduce the DC power. Why a 20% DC/AC ratio results in minimal clipping losses

What is DC to AC inverter ratio?

The DC to AC inverter ratio (also known as the Inverter Load Ratio, or “ILR”) is an important parameter when designing a solar project.

What is a good DC/AC ratio for a solar inverter?

Because the PV array rarely produces power to its STC capacity, it is common practice and often economically advantageous to size the inverter to be less than the PV array. This ratio of PV to inverter power is measured as the DC/AC ratio. A healthy design will typically have a DC/AC ratio of 1.25.

Why do inverters lose power if DC/AC ratio is too high?

The key driver here is the “clipping loss”: when the DC power feeding an inverter is more than the inverter can handle, the resulting power is “clipped” and lost. We at Folsom Labs have found that many designers are overly conservative when thinking about DC/AC ratios.

Should a 9 kW PV array be paired with an AC inverter?

Thus a 9 kW PV array paired with a 7.6 kW AC inverter would have an ideal DC/AC ratio with minimal power loss. When the DC/AC ratio of a solar system is too high, the likelihood of the PV array producing more power than the inverter can handle is increases.

Can a module rated power be bigger than an inverter rated?

We all know that the module rated power can be larger than the inverter rated power (within reason—inverters do have a max input current). But far fewer designers and engineers understand what are the practical limits. The DC to AC ratio (also known as the Inverter Load Ratio, or “ILR”) is an important parameter when designing a solar project.

More related information

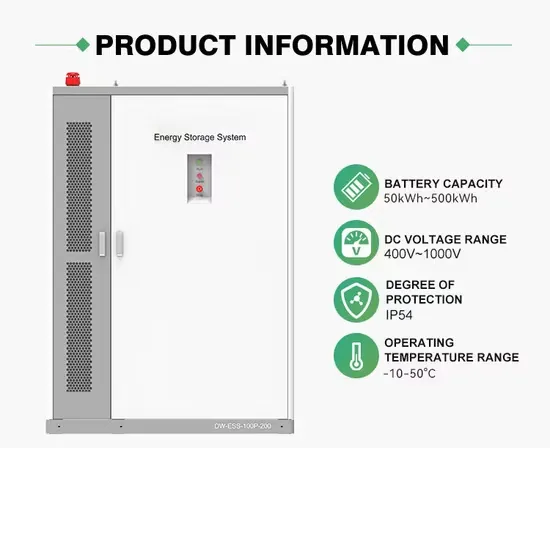

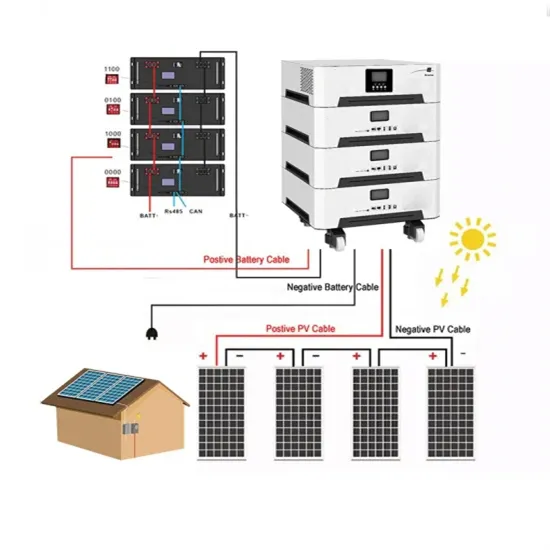

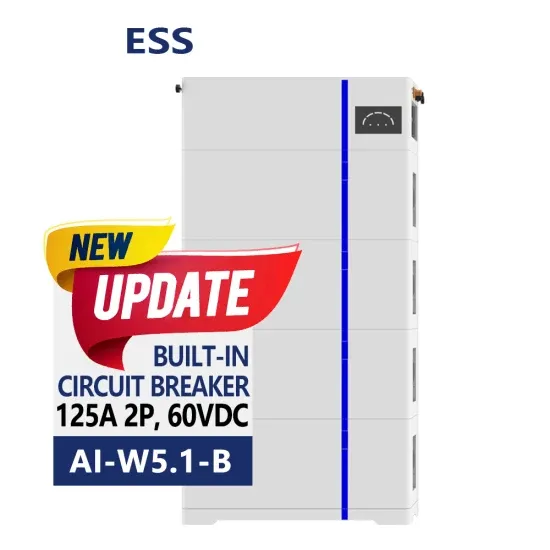

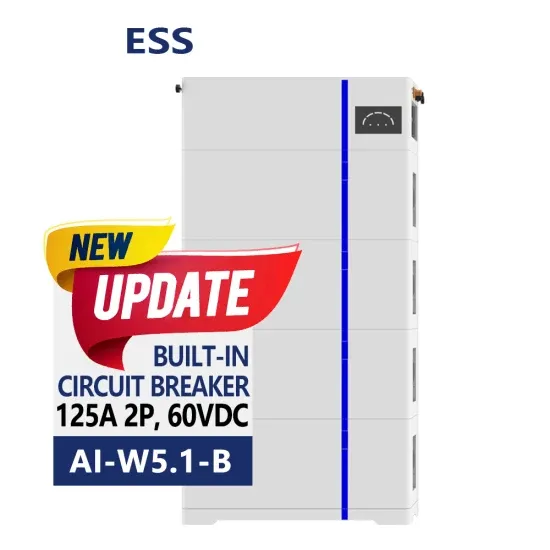

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

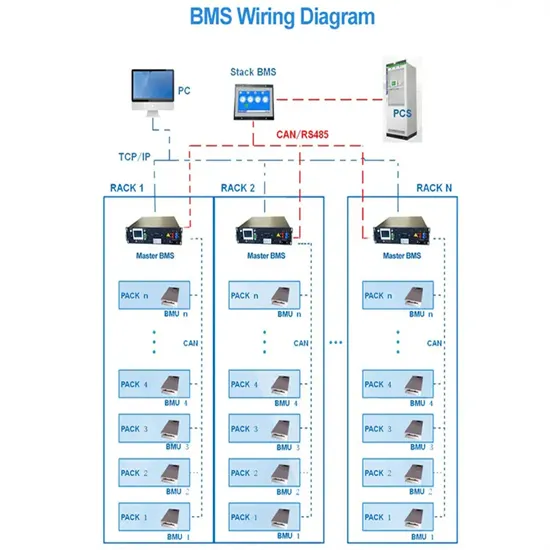

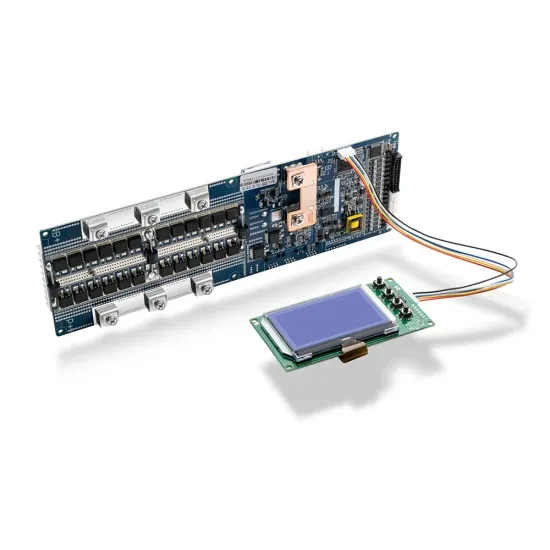

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.

300kW inverter AC output

300kW inverter AC output

AC 110V output energy storage inverter

AC 110V output energy storage inverter

12v inverter turns into 220 volts AC

12v inverter turns into 220 volts AC

Inverter output voltage through

Inverter output voltage through

The role of AC inverter

The role of AC inverter

Suifa photovoltaic inverter AC side

Suifa photovoltaic inverter AC side