Storage battery requirements

The batteries associated with UPS systems represent an unusual hazard. Remember that lead-acid batteries are devices that store incredible

Get Price

Safe Operations Near Roof Cellular Base Stations

What is a rooftop cellular base station? You have more than likely seen the cellular antennas attached to some rooftops in your district.

Get Price

46 CFR Part 111 Subpart 111.15 -

(c) Batteries must not evolve hydrogen at a rate exceeding that of a similar size lead-acid battery under similar charging condition. (d) Batteries must be constructed to take into account the

Get Price

Lead-Acid vs. Lithium-Ion Batteries for Telecom Base Stations

Conclusion: While lead-acid batteries remain a cost-effective option, lithium-ion batteries are gaining popularity due to their longer lifespan, reduced maintenance, and higher

Get Price

Battery Room Design Requirements – PAKTECHPOINT

It does not cover maintenance free or computer room type batteries and battery cabinets. Main keywords for this article are Battery Room Design

Get Price

Lithium-ion Battery For Communication Energy Storage System

Lithium-ion Battery For Communication Energy Storage System The lithium-ion battery is becoming more and more common in our daily lives. This new type of battery can

Get Price

Base Station Batteries

REVOV''s lithium iron phosphate (LiFePO4) batteries are ideal telecom base station batteries. These batteries offer reliable, cost-effective backup power for communication networks. They

Get Price

Use of Batteries in the Telecommunications Industry

The Alliance for Telecommunications Industry Solutions is an organization that develops standards and solutions for the ICT (Information and Communications Technology) industry.

Get Price

CHAPTER 12 ENERGY SYSTEMS

Not required for lead-acid and nickel-cadmium batteries at facilities under the exclusive control of communications utilities that comply with NFPA 76 and operate at less than 50 VAC and 60 VDC.

Get Price

Designing Ventilation For Battery Rooms | 2018-05-07

Typical battery SSBS are composed of batteries of the flooded lead-acid batteries, Valve Regulated Lead-Acid (VRLA), or nickel-Cadmium

Get Price

1910.268

Electrolyte (acid or base, and distilled water) for battery cells shall be mixed in a well ventilated room. Acid or base shall be poured gradually, while stirring, into the water. Water shall never

Get Price

Battery Room Design Requirements – PAKTECHPOINT

For flooded lead-acid, flooded Ni-Cd, and VRLA batteries, the ventilation system shall be designed to limit the maximum concentration of

Get Price

Tech Note | Battery Room Ventilation Requirements

Learn about hydrogen mitigation in battery systems. Understand the importance of preventing hydrogen buildup and relevant safety codes.

Get Price

Comprehensive Guide to Battery Room Protection: NFPA Codes

However, they also pose significant fire risks due to the chemical nature of batteries, particularly lithium-ion (Li-ion) and lead-acid batteries. To mitigate these risks, the

Get Price

IFC Design Provisions for DC Battery Systems in Electrical

IFC 2015 and previous versions This code has historically included provisions for battery systems in Chapter 6 as part of the Buildings Services and Systems. The code sets minimum threshold

Get Price

Chapter 12 Energy Systems: California Fire Code

Lead-acid and nickel-cadmium battery systems installed in Group U buildings and structures less than 1500 ft. (140 m) under the exclusive control of

Get Price

CHAPTER 12 ENERGY SYSTEMS

Not required for lead-acid and nickel-cadmium batteries at facilities under the exclusive control of communications utilities that comply with NFPA 76 and

Get Price

Designing Industrial Battery Rooms: Fundamentals and Standards

Industrial battery rooms require careful design to ensure safety, compliance, and operational efficiency. This article covers key design considerations and relevant standards.

Get Price

Battery Room Design Requirements – PAKTECHPOINT

In prefabricated substation and rack buildings, a stainless steel acid shield shall be provided below and behind each battery rack. The floor shield shall extend a minimum of 150 mm

Get Price

EngineeredSystems May 2018: Designing Ventilation For Battery

The International Fire Code (IFC) requirements are such that when the battery storage system contains more than 50 gallons of electrolyte for flooded lead-acid, nickel

Get Price

Storage battery requirements

For flooded lead-acid, flooded Ni-Cd, and VRLA batteries, the ventilation system shall be designed to limit the maximum concentration of hydrogen to 1% of the total volume of

Get Price

Optimization of Communication Base Station Battery

In the communication power supply field, base station interruptions may occur due to sudden natural disasters or unstable power supplies. This work studies the optimization of

Get Price

Maintaining Compliance in the VRLA Battery Room

Learn the requirements for VRLA batteries and how to be compliant with current regulation. Also learn the various rack compliance requirements and best practices including IBC, UBC, NEBS,

Get Price

6 FAQs about [Minimum distance between lead-acid batteries in communication base stations and buildings]

Do vented lead acid batteries need a separate battery room?

Vented lead acid batteries installed in medium voltage main substation buildings and unit substations, electrical equipment rooms and control system rack rooms shall not require a separate, dedicated battery room and shall be in accordance with SES E14-S02. The battery room and installation shall comply with IEEE 484, NFPA 70 and OSHA 29 CFR.

What are the safety requirements related to batteries & Battery rooms?

Employers must consider exposure to these hazards when developing safe work practices and selecting personal protective equipment (PPE). That is where Article 320, Safety Requirements Related to Batteries and Battery Rooms comes in.

What are the requirements for a battery installation?

1. Space Planning and Layout 900mm min Battery Room Layout 1200mm Primary Access End Access 1000mm Battery Racks Industrial battery installations require adequate spacing for maintenance, ventilation, and safety. The layout should accommodate: 2. Structural Requirements

Do I need a permit for a lead-acid battery system?

Operational permits shall not be required for lead-acid and nickel-cadmium battery systems at facilities under the exclusive control of communications utilities that comply with NFPA 76 and operate at less than 50 voltage alternating current (VAC) and 60 voltage direct current (VDC).

What are the requirements for a battery handling facility?

Floors shall be of acid resistant construction unless protected from acid accumulations. Face shields, aprons, and rubber gloves shall be provided for workers handling acids or batteries. Facilities for quick drenching of the eyes and body shall be provided within 25 feet (7.62 m) of battery handling areas.

Do you need documentation before entering a battery room?

It is a requirement to have all the documentation in place prior to authorized personnel entering a battery room to perform a specific work task on a battery system under normal operating conditions. However, it is likely the employee will need to enter the battery room to deal with a battery system that is not operating normally.

More related information

-

What are the lead-acid batteries for Sudan border communication base stations

What are the lead-acid batteries for Sudan border communication base stations

-

Do lead-acid batteries in communication base stations affect wind power generation networks

Do lead-acid batteries in communication base stations affect wind power generation networks

-

Safe distance of hybrid energy batteries for communication base stations

Safe distance of hybrid energy batteries for communication base stations

-

Optimization of lead-acid batteries for communication base stations by the end of the year

Optimization of lead-acid batteries for communication base stations by the end of the year

-

What are the lead-acid batteries for communication base stations in Sao Tome and Principe

What are the lead-acid batteries for communication base stations in Sao Tome and Principe

-

Which manufacturers produce lead-acid batteries for communication base stations in Colombia

Which manufacturers produce lead-acid batteries for communication base stations in Colombia

-

Tax rate for lead-acid batteries for communication base stations

Tax rate for lead-acid batteries for communication base stations

-

6 9MWh of batteries for major communication base stations in Asia

6 9MWh of batteries for major communication base stations in Asia

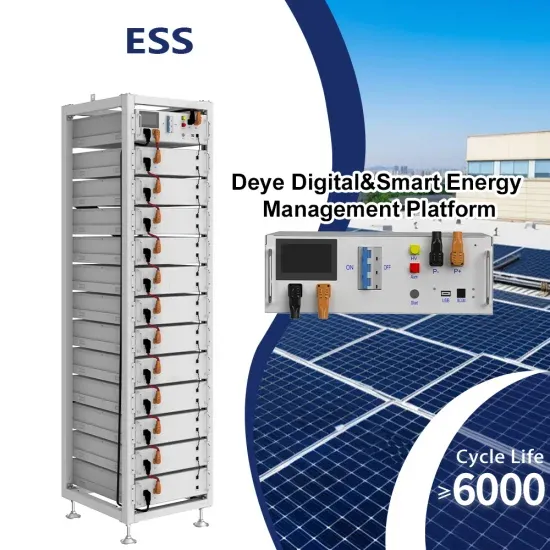

Commercial & Industrial Solar Storage Market Growth

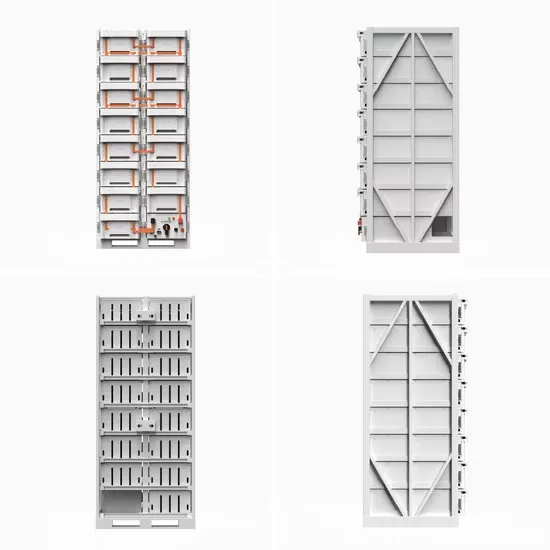

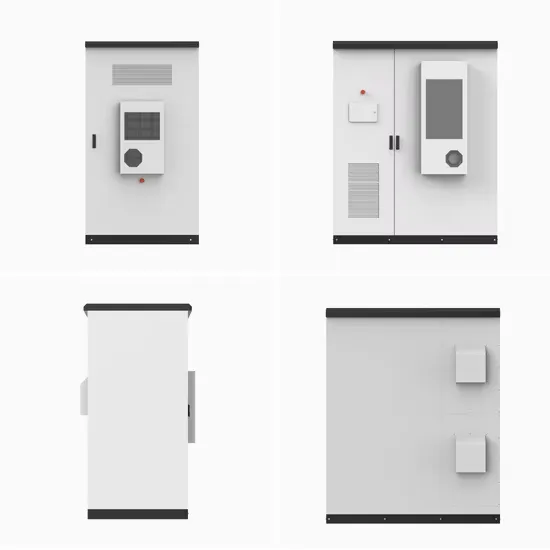

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.