The Safety Cabinet Warehouse

The Safety Cabinet Warehouse – for safe storage of Flammable and Hazardous Materials, Chemical Goods, and Dangerous Goods at wholesale prices.

Get Price

Inspection Checklist for Your Lithium-ion Battery

In our checklist, we''ve put together suggested regular checks that will help you detect any potential problems with the way your battery charging

Get Price

Quality Assurance – Electrios Consultants

Electrios provides factory inspections, based on client requirements and product specifications. Inspections impart confidence in the quality of production and reliability of products.

Get Price

Mitsubishi Electric Power Products, Inc. BC7 Battery Cabinet

Installation, Operation, & Maintenance Manual Built for Mitsubishi Electric Power Products, Inc. by

Get Price

Battery Charger and Rectifier Test Procedure

The above value must be tolerable with the limits given by Manufacturer Battery Charger Test Procedure Standard: Tests according to IEC Standard 61951-1 1- Mandatory Condition: The

Get Price

Battery Inspection Checklist

This checklist, which includes both visual and technical inspections, assists in identifying difficulties with mounting, cables, electrolyte

Get Price

Battery Inspection Checklist

This checklist, which includes both visual and technical inspections, assists in identifying difficulties with mounting, cables, electrolyte levels, & voltage to ensure proper

Get Price

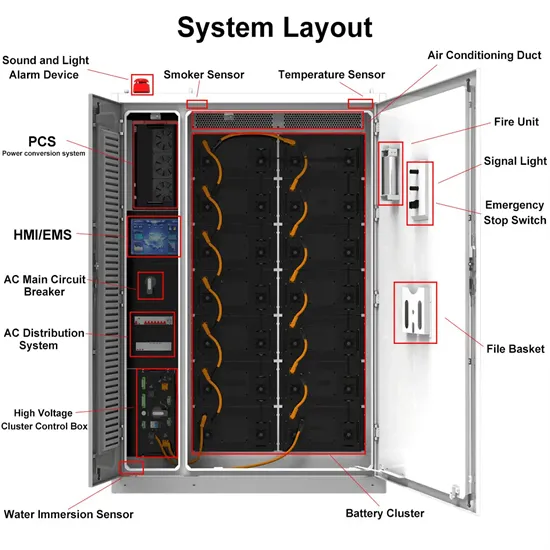

Battery Cabinet

Since our establishment in 1994, we are dedicated to serve our partner with whole solution of power system, professional technical solution, quality

Get Price

Battery Cabinet Inspection Checklist | We Group E-Site

As modular battery architectures dominate new installations, perhaps we''ll see inspection intervals tighten from months to minutes. The real question remains: How soon will your team

Get Price

Battery FAT vs SAT Testing Explained | Factory vs Site

Energy storage battery systems require similar "pre-purchase inspection" and "post-delivery verification"—this is where FAT (Factory Acceptance Testing) and SAT (Site Acceptance

Get Price

Battery Inspection Checklist: Section A

The document is a battery inspection checklist used by the U.S. Army Corps of Engineers (COE) for inspecting batteries. It collects information about the customer, equipment, and facility

Get Price

Ten Point Weekly Generator Inspection Checklist

Battery Check: Verify that the battery is charged and corrosion-free. This prepares it for a seamless start-up. It can be nice to have a battery

Get Price

Inspection Checklist for Your Lithium-ion Battery Charging Cabinet

In our checklist, we''ve put together suggested regular checks that will help you detect any potential problems with the way your battery charging cabinet or store has been

Get Price

A documented safety inspection provides increased safety

By hiring asecos certified service technicians for annual safety inspections, you will receive a correctly performed inspection according to the manufacturer''s recommen-dation, receive test

Get Price

Energy storage container factory inspection report

Energy Storage Inspection 2024: Fronius nuovamente tra i migliori Fronius GEN24 Plus e BYD Battery-Box Premium: i due conquistano la Top 3 dell''''Energy Storage Inspection anche nel

Get Price

Inspection Checklist for Your Lithium-ion Battery

Inspection Checklist Creating an inspection checklist for your Storemasta battery charging and storage cabinet will help you maintain safety.

Get Price

版本说明书

WORKING ENVIRONMENT REQUIREMENTS Install and operate the Battery Cabinet in accordance with environmental specifications contained in this manual and avoid exposure to

Get Price

Battery Storage and Charging Area Inspection Checklist

Use this battery inspection checklist to ensure your battery storage and charging areas are in compliance with OSHA battery storage standards.

Get Price

Battery Inspection Checklist: Section A

The document is a battery inspection checklist used by the U.S. Army Corps of Engineers (COE) for inspecting batteries. It collects information about the

Get Price

2018 Title Contents

Even if a company installs a NEBS-certified battery rack in a site, the building inspector can still require the rack to be certified to IBC or any other building code that city or state has adopted.

Get Price

Battery Enclosure Inspection Checklist for Battery Builder

This checklist is typically used by battery builders or technicians who are responsible for assembling and inspecting battery enclosures. It helps them to systematically go through each

Get Price

Quality Assurance – Electrios Consultants

Electrios provides factory inspections, based on client requirements and product specifications. Inspections impart confidence in the quality of production and

Get Price

Factory Acceptance Test report

4 Visual Inspection In order to assess the quality of the manufactured control equipment/enclosure a visual inspection will be carried out. Each control equipment/enclosure

Get Price

Battery FAT vs SAT Testing Explained | Factory vs

Energy storage battery systems require similar "pre-purchase inspection" and "post-delivery verification"—this is where FAT (Factory Acceptance Testing)

Get Price

Liebert® EXS External Battery Cabinet Installer/User Guide

This manual contains important instructions that should be followed during installation of your VertivTM Liebert® EXS Battery Cabinet and accessories. Read this manual thoroughly, paying

Get Price

Uninterruptible Power Supply (UPS) Backup Battery

Battery Cabinets Arimon designs and manufactures custom uninterruptible power supply (UPS) backup battery cabinets, battery racks and accessories for the

Get Price

Battery Pack Assembly Line Vision Inspection Systems

Implementing Vision Inspection Systems: Key Considerations for Battery Production Integrating vision inspection into battery pack assembly requires careful planning to maximize

Get Price

5 FAQs about [Battery cabinet factory inspection]

What is a battery inspection checklist?

Regular battery inspections assist to ensure optimal performance & safety. Following this checklist makes sure that all important components are evaluated and any necessary steps are performed to keep the system operational. This detailed Battery Inspection Checklist ensures battery performance and safety.

What is a battery inspection?

The first level of inspection involves a thorough visual examination of the battery’s physical condition. This step checks for any mechanical or structural faults that could hinder performance. Mark “OK,” “Not OK,” or “N/A” in the appropriate boxes for each point.

How do you test a battery?

Battery Load Test: Perform a load test by providing a 200A load for 10-15 seconds. The voltage per battery should not fall below 9.6 V DC. Open/Short Circuit Check: Make sure the battery system has no open or short circuits. According to the inspection results, follow these recommendations:

How do you check a battery in a washing machine?

Unit Number: Write down the machine unit number in which the battery is placed. Note the machine’s model. Last Fitment Date: Mention the date that the battery was last installed in the machine. The first level of inspection involves a thorough visual examination of the battery’s physical condition.

How do I know if my battery is bad?

Make sure the battery is properly placed and that the bracket is not damaged or corroded. Check the battery box (also known as the battery case) for fractures, distortion, or damage. Check that the battery guard cover is intact and appropriately covering the battery. Ensure that the poles are in good shape, with no excessive wear or corrosion.

More related information

-

Chile Energy Storage Cabinet Battery Factory

Chile Energy Storage Cabinet Battery Factory

-

Latvian Photovoltaic Energy Storage Cabinet Battery Factory

Latvian Photovoltaic Energy Storage Cabinet Battery Factory

-

Where can I find a battery cabinet wholesale factory in Sierra Leone

Where can I find a battery cabinet wholesale factory in Sierra Leone

-

Cambodia Energy Storage Cabinet Battery Factory

Cambodia Energy Storage Cabinet Battery Factory

-

Djibouti Outdoor Communication Battery Cabinet Factory

Djibouti Outdoor Communication Battery Cabinet Factory

-

Is there a battery cabinet factory in the capital

Is there a battery cabinet factory in the capital

-

Domestic battery cabinet processing factory

Domestic battery cabinet processing factory

-

Hungary battery cabinet factory system

Hungary battery cabinet factory system

Commercial & Industrial Solar Storage Market Growth

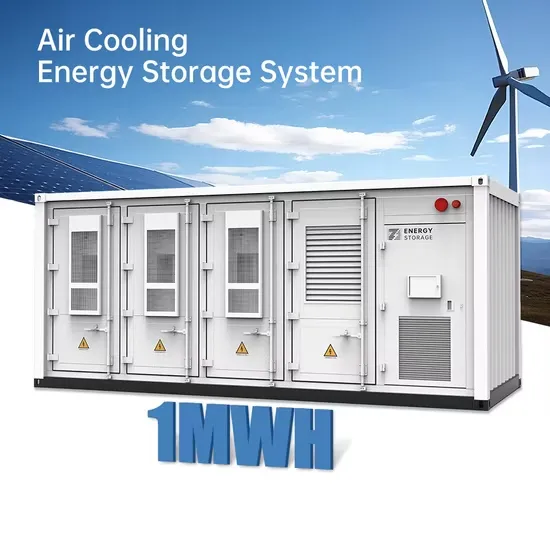

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.