Are battery packs Lithium?

Not all battery packs are lithium-based, but the vast majority of modern battery packs use lithium technology, especially lithium-ion and lithium-polymer. These types of

Get Price

Characterization of in-situ material properties of pouch lithium-ion

The tensile strength of the jellyroll has a unique hardening controlled by the strength of various layers in the jellyroll cross-section. As the modeling techniques have further

Get Price

Tensile parameters of lithium-ion battery cell components.

Most literature on the mechanical properties of Lithium-ion battery cells is concerned with the mechanical behavior of jellyroll or Lithium-ion battery when the state of charge (SOC) is 0%....

Get Price

A review on electrical and mechanical performance parameters in lithium

A comprehensive review of the lithium-ion battery pack is presented to acknowledge the major factors that influence the structural performance and the electrical

Get Price

Mechanical Properties of Macromolecular Separators

According to the requirements of the United States Advanced Battery Consortium (USABC) for lithium-ion battery separators, the

Get Price

The Fundamentals of Battery/Module Pack Test

Battery module and pack testing is critical for evaluating the battery''s condition and performance. This includes measuring the state of charge (SoC), depth of discharge (DoD), direct current

Get Price

LITHIUM BATTERIES 101

Introduction A brief history and overview of advanced battery chemistry: The first lithium-ion battery prototype Popular lithium (ion) cell types: What are batteries made of? What are lead

Get Price

SEPARATOR PRODUCT PORTFOLIO

SEPARATOR PRODUCT PORTFOLIO ENTEK Membranes LLC ofers a broad portfolio of separators for Li-primary, Li-metal, and Li-ion battery manufacturers, as well as a customised

Get Price

No.i245 Piercing and Tensile Testing

isplacement value is about the same. From the above, it can be assumed that at 60 °C, there is no decrease in strength of the lithium-ion battery separator, despite the apparent Fig. 2 Test

Get Price

Cell Component Mechanical Tests

Tensile test on a 6 µm copper foil with the most advanced non-contacting video extensometer without the need of marking (and potentially damaging) the sample. We posted

Get Price

General overview on test standards for Li-ion batteries, part 1

Electric and Hybrid Vehicle Propulsion Battery System Safety Standard - Lithium-based Rechargeable Cells.

Get Price

General overview on test standards for Li-ion batteries, part 1

Test specifications for packs and systems - High-power applications. Test specifications for packs and systems - High-energy applications. Test specification for lithium-ion traction battery packs

Get Price

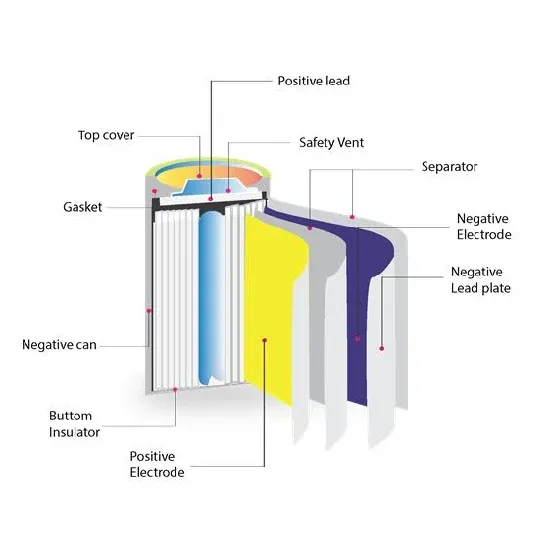

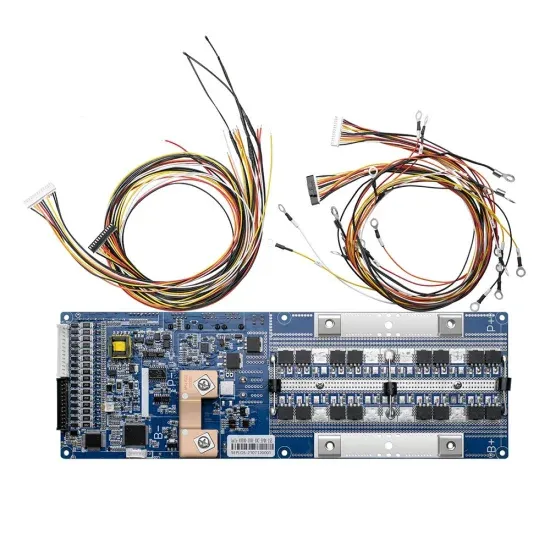

What Are Battery Cells, Battery Modules, And Battery

The process of assembling lithium battery cells into groups is called PACK, which can be a single battery or a battery module connected in

Get Price

Tensile, Puncture, and Peel Testing of Lithium-Ion Batteries

In this article, we will take a look at the solutions ideal for tensile, puncture, and peel testing of lithium-ion batteries.

Get Price

Separator Film Testing for Electric Vehicle Batteries

Tensile and coefficient of friction testing are critical for ensuring the separator film can withstand manufacturing of the battery, while puncture resistance is a

Get Price

Tensile parameters of lithium-ion battery cell

Most literature on the mechanical properties of Lithium-ion battery cells is concerned with the mechanical behavior of jellyroll or Lithium-ion battery when

Get Price

Laser wobble welding of steel to Aluminium busbar joints for Li-ion

In this work, Laser wobble welding of Steel to Aluminium busbar joints was investigated for Li-ion battery pack applications. The effect of wobble amplitude on the

Get Price

UL 2612 – Battery Pack Retention Strength Testing

Battery pack retention strength testing, as specified in UL 2612, involves subjecting the battery pack to various environmental and mechanical stressors. The goal is to evaluate its ability to

Get Price

A review on electrical and mechanical performance parameters in

A comprehensive review of the lithium-ion battery pack is presented to acknowledge the major factors that influence the structural performance and the electrical

Get Price

Characterization of in-situ material properties of pouch lithium-ion

As a result, their tensile strength is much smaller than their compressive strength. Therefore, the homogenized response of the cell will be different in three principal directions of

Get Price

The Ultimate Guide to 18650 Battery Packs: Design,

The 18650 battery pack is a modular energy storage system built from 18650 cylindrical lithium-ion cells, each measuring 18mm in diameter and 65mm in

Get Price

The strength of a constrained lithium layer

The high strength of the bonding between lithium and quartz in the compression testing was confirmed by performing a tensile test on the sandwiched lithium layer immediately

Get Price

CHARACTERIZATION OF ALUMINIUM-TO-ALUMINIUM

The increasing number of electric vehicles (EV) introduces a need for advancements in battery technology, particularly in the welding of battery pack assemblies. The aim of this bachelor''s

Get Price

Products | Avocet Electrofoils (AEF)

High Tensile Battery Foil Battery foil with higher mechanical strength, allowing for thicker and heavier slurry coatings ensuring maximum cell performance.

Get Price

Standardizing mechanical tests on li-ion batteries to develop a

Here, through our test data and simulation results, we reveal that many existing types of cell-level mechanical tests can only result in a narrow stress state and thus could not

Get Price

6 FAQs about [What is the reasonable tensile strength of a pack lithium battery ]

What are the most common test types for lithium-ion battery testing?

In this article, we will go through the grip recommendations to the most common tests types within lithium-ion battery testing. These are tension, puncture, and peel.

Do vibration and temperature influence performance in lithium-ion batteries?

However, there has been limited research that combines both, vibration and temperature, to assess the overall performance. The presented review aims to summarise all the past published research which describes the parameters that influence performance in lithium-ion batteries.

Can a lithium-ion battery pack be vibration tested?

However, previous research acknowledges that different vibration tests proposed in standards and regulations for lithium-ion battery packs vary substantially in the levels of energy and frequency range (Kjell and Lang, 2014) so there is still a big challenge to emulate a test that represents the real working condition of electric vehicles.

How to test a lithium ion battery?

In this article, we will take a look at the solutions ideal for tension, puncture, and peel testing of those batteries. A test solution for the lithium-ion battery industry would typically consist of material testing machine, fitted with a high accuracy load cell, analytical software and grips suitable for securing the battery during the test.

Why are there no standards for mechanical tests on battery cells?

First, there are still no widely-accepted standards for mechanical tests on battery cells. Second, no general agreements have been made on which model (s) should be used to describe the mechanical behavior. These two gaps are inherently interconnected because tests should serve as the calibration of models and models can explain the tests.

Why is mechanical characterization of Li-ion batteries important?

In a narrow range of stress state, various models have nearly identical performance. Mechanical characterization of Li-ion battery cells is becoming increasingly important as the community becomes more aware that the underlying mechanisms of battery failure and degradation involve the complex interplay between electrochemistry and mechanics.

More related information

-

What is the normal voltage of Angola lithium battery pack

What is the normal voltage of Angola lithium battery pack

-

What is the charging voltage of a 74v lithium battery pack

What is the charging voltage of a 74v lithium battery pack

-

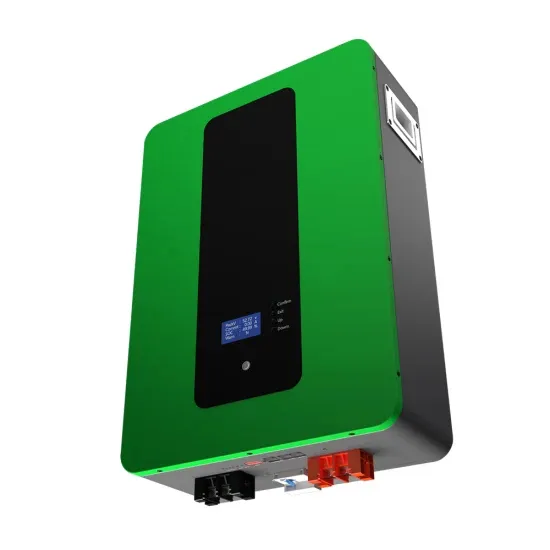

What does the lithium battery pack assembly include

What does the lithium battery pack assembly include

-

Armenia lithium iron phosphate battery pack for sale

Armenia lithium iron phosphate battery pack for sale

-

Pakistan 12v lithium battery pack

Pakistan 12v lithium battery pack

-

Lithium battery 7 2v battery pack

Lithium battery 7 2v battery pack

-

Multifunctional lithium battery pack

Multifunctional lithium battery pack

-

Turkmenistan large-cell lithium battery pack

Turkmenistan large-cell lithium battery pack

Commercial & Industrial Solar Storage Market Growth

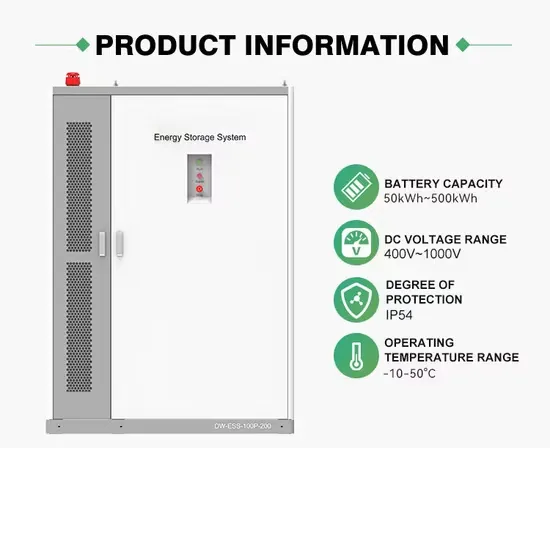

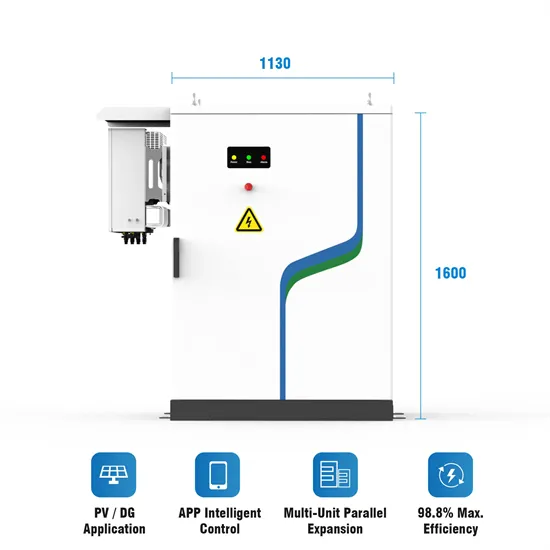

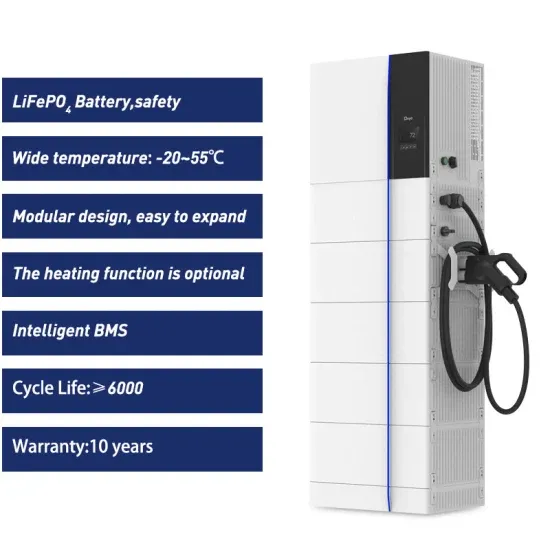

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.