Pre-assembled energy storage battery production and assembly

Energy Storage Battery Production: A Comprehensive Overview In this article, we provide a detailed insight into the manufacturing process of energy storage batteries, highlighting key

Get Price

Lithium Battery Pack Assembly: A Comprehensive Guide

As the world transitions towards sustainable energy solutions, the demand for high-performance lithium battery packs continues to soar. At the

Get Price

Pre-fabricated Battery Energy Storage Systems

Pre-fabricated BESS are fully assembled energy storage solutions that come ready to integrate with existing power systems. They typically

Get Price

Pre-assembled Battery Pack

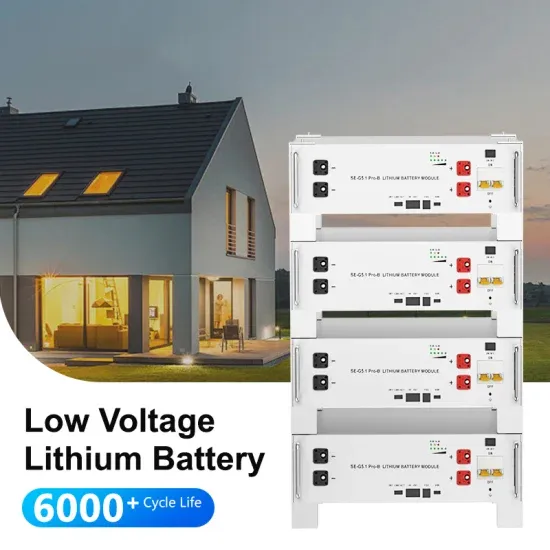

Completed with 12V,24V,48V Lifepo4 battery pack,custom lithium ion battery suppliers,large power for 15kwh,16kwh battery energy storage system with fantastic prices

Get Price

Rethink Manufacturing of Battery Energy Storage Systems

Bright Machines configured a microfactory with thirteen robotic cells which performed all the assembly steps including testing and sorting of individual battery cells, placing the cells into

Get Price

A Deep Dive into Lithium-Ion Battery (LIB) Manufacturing

Lithium-ion battery manufacturing is the method of producing lithium-ion batteries that employ lithium ions as their main source of energy. The manufacturing

Get Price

(Infographics #3) Battery Making at a Glance

(Infographics #3) Battery Making at a Glance The manufacturing process of lithium-ion batteries consists largely of 4 big steps of electrode

Get Price

Li-Ion battery assembly lines for energy storage systems

BM-Rosendahl offers tailor-made assembly lines designed to streamline the production of ESS batteries. Our solutions are adaptable to various cell types—including cylindrical, prismatic,

Get Price

How Are Lithium Batteries Manufactured? A Step-by-Step

How are lithium batteries made step by step? Lithium batteries are manufactured through a multi-stage process: raw material preparation, electrode production, cell assembly, electrolyte

Get Price

Innovating battery assembly

We have outlined a complete battery assembly process for prismatic cells – from the single cell to the finished battery pack. We help our customers develop unique joining processes and select

Get Price

Turnkey lines for battery pack technologies

We offer modular and flexible solutions to cover many fields, such as energy storage systems of research and development machines, as well as complete

Get Price

Cell Final Assembly and Finishing

There are 4 steps in the final assembly battery cell manufacture: Filling, Formation and Sealing. Ageing, Final Control Checks.

Get Price

Li-Ion battery assembly lines for energy storage systems

BM-Rosendahl offers tailor-made assembly lines designed to streamline the production of ESS batteries. Our solutions are adaptable to various cell

Get Price

Assembly line for battery modules and battery packs

For cell/module pack assembly, PIA Automation offers flexible and highly automated systems for the efficient production of battery cells, modules, and battery packs. These systems are

Get Price

Electric vehicle battery production process

Our electric vehicle battery assembly, joining and inspection technologies drive productivity, quality, and performance of your electric vehicle batteries

Get Price

Key Points of Lithium Battery PACK Manufacturing

Dive into the detailed process behind these essential energy storage solutions! From selecting and matching battery cells to assembling,

Get Price

BATTERY MODULE AND PACK ASSEMBLY PROCESS

Based on the brochure "Lithium-ion battery cell production process", this brochure schematically illustrates the further processing of the cell into battery modules and finally into a battery pack.

Get Price

ES-10001000-EU | 1MW 1106kWh Energy Storage System

The system delivered >95% pre-assembled, having already been manufactured, assembled, commissioned, and tested at our production facilities, a proper plug-n-play containerized

Get Price

Current and future lithium-ion battery manufacturing

Figure 1 introduces the current state-of-the-art battery manufacturing process, which includes three major parts: electrode preparation, cell assembly, and battery

Get Price

Key Points of Lithium Battery PACK Manufacturing Process

Dive into the detailed process behind these essential energy storage solutions! From selecting and matching battery cells to assembling, testing, and packaging, discover the

Get Price

Lithium-ion Battery Module and Pack Production Line

At this stage, the battery module will be assembled into a complete energy storage battery pack, including the case, heat dissipation system, BMU

Get Price

Energy Storage Batteries Manufacture

1.3 Cell Assembly The electrodes, separators, and electrolytes are assembled into battery cells through: Stacking or Winding: Depending on battery type (prismatic, cylindrical, or pouch

Get Price

Pre-fabricated Battery Energy Storage Systems

Pre-fabricated BESS are fully assembled energy storage solutions that come ready to integrate with existing power systems. They typically include battery modules,

Get Price

EnerVenue Energy Rack includes pre-assembled

The stationary energy storage solution includes a nickel-hydrogen battery, the battery management system and cabling.

Get Price

Energy Storage Battery Manufacture

As the demand for energy storage batteries surges, LondianESS remains at the forefront with innovative, reliable, and eco-friendly manufacturing solutions. Whether for grid storage,

Get Price

A Collaborative Design and Modularized Assembly for

With the core objective of improving the long-term performance of cabin-type energy storages, this paper proposes a collaborative design and

Get Price

6 FAQs about [Pre-assembled energy storage battery production and assembly]

What does the battery production department do?

The battery production department focuses on battery production technology. Member companies supply machines, plants, machine components, tools and services in the entire process chain of battery production: From raw material preparation, electrode production and cell assembly to module and pack production.

What is the process chain of lithium-ion battery production?

Member companies supply machines, plants, machine components, tools and services in the entire process chain of battery production: From raw material preparation, electrode production and cell assembly to module and pack production. PEM of RWTH Aachen University has been active for many years in the area of lithium-ion battery production.

Why do batteries need to be reprogrammed?

Irregularities such as part tolerances, position deviations, or contaminations tend to complicate the process. Any error in this process step can damage the battery’s exterior, lead to weak joints, harm the sensitive cells, and lead to dangerous short circuits afecting the performance and the overall safety of the battery.

How does a battery tray assembly work?

The battery tray assembly consists of several production steps. Depending on the battery design and manufacturing processes, manual tightening with bolt positioning and process control, or flow drill fastening with K-Flow technology can bring the needed process quality, productivity and flexibility.

What are the different types of battery modules?

Comparison of battery modules Pouch cell battery module Cell Tensioning Gluing Bandage Pouch cell battery module Prismatic cell battery module

Why do batteries need to be sealed?

At the end of the battery manufacturing process, the critical areas of the battery need to be sealed to avoid corrosion. State-of-the-art battery designs have many surface breaks, trim edges and joints. For example, mechanical cover-to-tray joining can cause slight damage to the lid’s coating.

More related information

-

Mauritius energy storage battery production

Mauritius energy storage battery production

-

Tuvalu household energy storage battery assembly

Tuvalu household energy storage battery assembly

-

Heishan Energy Storage Battery Production

Heishan Energy Storage Battery Production

-

Jamaica Industrial Energy Storage Battery Assembly

Jamaica Industrial Energy Storage Battery Assembly

-

Energy Storage Battery Cabinet Assembly Cost Site

Energy Storage Battery Cabinet Assembly Cost Site

-

Belarusian energy storage cabinet battery production

Belarusian energy storage cabinet battery production

-

Energy storage battery warehouse production

Energy storage battery warehouse production

-

Indian energy storage battery assembly plant

Indian energy storage battery assembly plant

Commercial & Industrial Solar Storage Market Growth

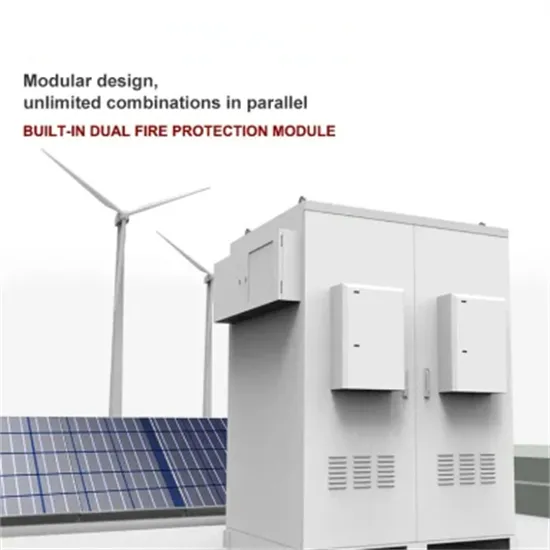

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.