STANDARDIZATION/INDIGENIZATION OF ELECTRICAL

Need for standardization comes in as the world over, variant technologies are being used for the MRTS/LRT/High speed rails all of whom are equally reliable and meet required safety

Get Price

IEEE DC Power System Design Recommended Practice

IEEE Recommended Practice for DC power system design in stationary applications. Covers batteries, chargers, distribution, and protection. Technical standard.

Get Price

Two-Way Communication Systems for Rescue

Code compliant two-way communication systems for rescue assistance require a central control point where the call boxes call for emergency assistance. The

Get Price

EV Charging Station Connector Requirements: ISO 15118

The ISO 15118 standard defines the power and communication interface between a battery-powered electric vehicle (BEV) or plug-in hybrid electric vehicle (PHEV) and the

Get Price

1910.269

Power generation, transmission, and distribution installations, including related equipment for the purpose of communication or metering that are accessible only to qualified employees; NOTE

Get Price

Standards and Practices for Communications Environments

This document provides guidelines and standards required for all design, installation, testing, modification, and removal of telecommunications cabling infrastructure in buildings where

Get Price

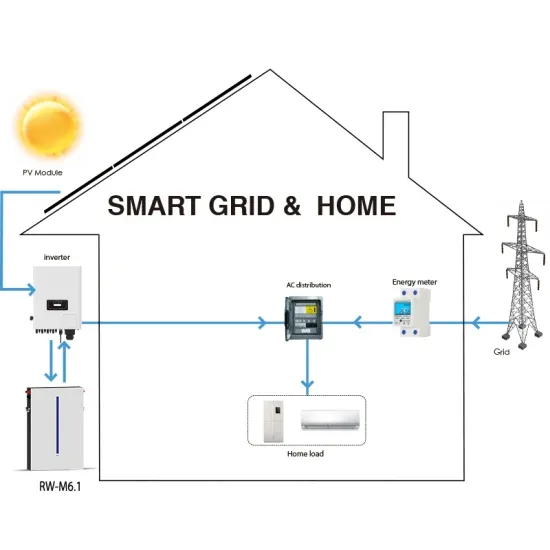

TECHNICAL SPECIFICATIONS OF ON-GRID SOLAR PV

3. Definition electronics, which feeds generated AC power to the Grid. Other than PV Modules and Inverter/Inverters, the system consists of Module Mounting Structures, appropriate DC

Get Price

946-2020

Abstract: Recommended practices for the design of dc power systems for stationary applications are provided in this document. The components of the dc power system

Get Price

Rack Mount DC Distribution Panel | 12V DC | 24V DC | 48V DC

The DST is a high density Telecom Rackmount DC Distribution Panel designed to accommodate virtually any 48V, 24V or 12V DC power distribution requirement. Its flexibility makes it ideal for

Get Price

IEEE DC Power System Design Recommended

IEEE Recommended Practice for DC power system design in stationary applications. Covers batteries, chargers, distribution, and protection. Technical

Get Price

Technical literature

Technical literature DC Distribution Box and AC Distribution Box Solar ACDB ACDB is an important part of SPV system. It gives extra protection to the system in case of failures on load

Get Price

TECHNICAL SPECIFICATION FOR

The electrical station systems shall be required to provide the voltage class indicated in Table-1.1 for operation of various plant equipment, operating mechanisms, plants, and control &

Get Price

Direct Current in Buildings

The National Electrical Manufacturers Association (NEMA) conducted a survey with vendors, technical experts, research laboratories, standards development organizations, and other

Get Price

Substation Primary Design Standard

1. Introduction The substation design responsibilities are broadly divided into primary and secondary systems. The primary systems are the high voltage, civil and structural and building

Get Price

Rack Mount DC Distribution Panel | 12V DC | 24V DC

The DST is a high density Telecom Rackmount DC Distribution Panel designed to accommodate virtually any 48V, 24V or 12V DC power distribution

Get Price

Standards and Practices for Communications Environments

This guide is for anyone who will install, test, modify, or remove District government owned or operated communications infrastructure or who is responsible for overseeing these tasks, such

Get Price

Communications Distribution System Requirements

The data racks are standard 19-inch racks x 7 feet high, floor and top-braced, with working clearance (3 feet front, back, and side) around the rack(s). The TR should conform to National

Get Price

3 Designs of DC Distribution Systems In Power Substations

The method of connection of the battery, battery charger, and DC distribution systems depends on the duty, the type or load, and whether the system needs to be

Get Price

Communications System Power Supply Designs

Voice-over-Internet-Protocol (VoIP), Digital Subscriber Line (DSL), and Third-generation (3G) base stations all necessitate varying degrees of complexity in power supply design. We

Get Price

SUB-STATION LIGHTING

There shall be provision for DC emergency lighting system in strategic locations including staircase, corridors, control rooms, battery charger room, LT switchgear room in control room

Get Price

1185-2019

Scope: This recommended practice provides guidance for wire and cable installation practices in generating stations and industrial facilities. It covers installation of

Get Price

1427-2020

This guide, covering three-phase ac systems from 1 kV to 800 kV, provides recommended electrical operating, safety clearances, and insulation levels in air-insulated electric supply

Get Price

Auxiliary DC Control Power System Design for Substations

Abstract—The most critical component of a protection, con-trol, and monitoring system is the auxiliary dc control power system. Failure of the dc control power can render fault detection

Get Price

IEEE Recommended Practice for the Design of DC Power

This recommended practice fulfils a need within the industry to provide common or standard practices for the design of dc power systems. The design features are applicable to all

Get Price

6 FAQs about [Standards for DC distribution boxes in communication base stations]

What is a Recommended Practice for a stationary DC power system?

Guidance in selecting the quantity and types of equipment, the equipment ratings, interconnections, instrumentation and protection is also provided. This recommendation is applicable for power generation, substation, and telecommunication applications. Scope: This recommended practice provides guidance for the design of stationary dc power systems.

What should be considered when designing a substation's de system?

Tn cases where the power consumption is relatively -48 V converters). In such cases, considerations for additional needs, such as required incremental power, voltage regulation, and high-frequency noise should be made when designing the main substation's de system. For additional guidance refer to IEEE Std 1818. and 12 V de.

What is a DC power system?

This introduction is not part of IEEE Std 946-2020, IEEE Recommended Practice for the Design of DC Power Systems for Stationary Applications. DC power systems continue to play a vital role in generating station, substation, and telecom controls and providing backup for emergencies.

What are the components of a DC power system?

The components of the dc power system addressed by this document include lead-acid and nickel-cadmium storage batteries, static battery chargers, and distribution equipment. Guidance in selecting the quantity and types of equipment, the equipment ratings, interconnections, instrumentation and protection is also provided.

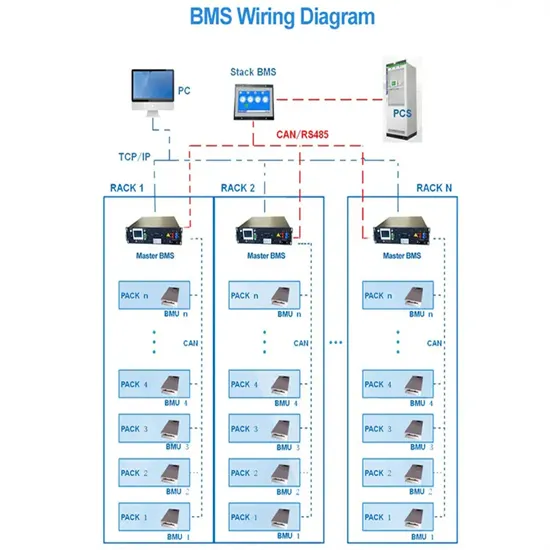

What is a bdcbb & PD Bay in a telecommunications system?

For additional guidance, refer to IEEE Std 1818. recharge the battery, and N+ I redundancy as a maintenance spare. The batte1y often consists of two or more of the telecommunications systems. The overcurrent protection (OCP) system is made up of pri1nary bays bays (BDCBB), power distributing (PD) bays, or similar tenns] (see Figure 4).

What is DC power distribution?

DC power distribution consists of cabinets, or relay racks, usually by way of a second level of overcurrent protection (fuse panels) \Vithin bays. A microprocessor-based controller governs de plant operation and provides monitoring and alarm reporting. connected.

More related information

-

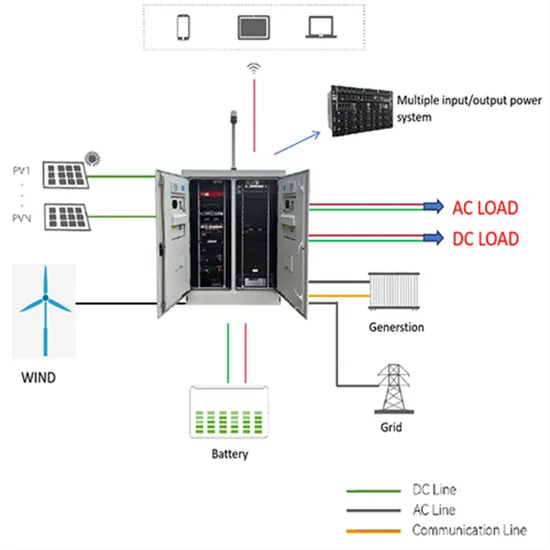

Distribution of inverters in Madagascar s communication base stations

Distribution of inverters in Madagascar s communication base stations

-

Which solar 12V DC power plant is best for communication base stations

Which solar 12V DC power plant is best for communication base stations

-

Energy efficiency rating standards for wind and photovoltaic power generation at communication base stations

Energy efficiency rating standards for wind and photovoltaic power generation at communication base stations

-

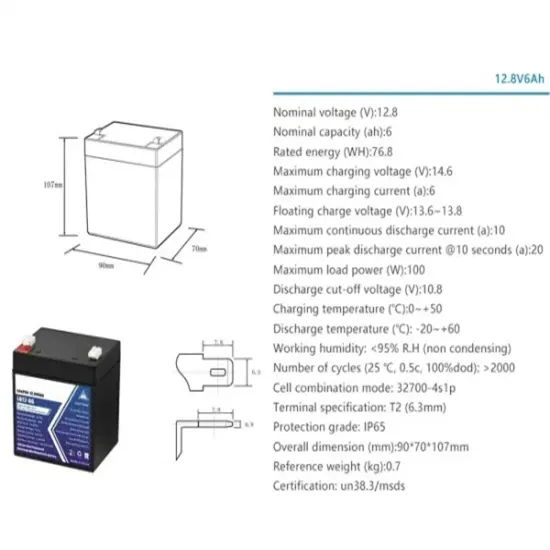

Battery pack configuration standards for communication base stations

Battery pack configuration standards for communication base stations

-

Safe distance of hybrid energy batteries for communication base stations

Safe distance of hybrid energy batteries for communication base stations

-

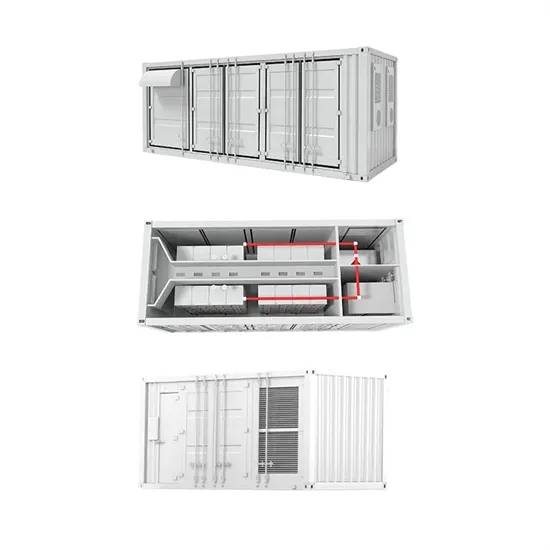

Design requirements for energy storage cabinets in communication base stations

Design requirements for energy storage cabinets in communication base stations

-

Notice of suspension of wind and solar hybrid work at communication base stations

Notice of suspension of wind and solar hybrid work at communication base stations

-

Residents disagree with the installation of hybrid energy for communication base stations

Residents disagree with the installation of hybrid energy for communication base stations

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.