2024 World''s Top 20 Silicon Material/Wafer Manufacturers

On the first day of the conference, PVBL''s annual ranking of the Top 20 Global Silicon Material/Wafer Manufacturers was announced. Most of the companies in the above list

Get Price

Top 20 Solar Panel Manufacturers in the World

In this article, we will provide a comprehensive list of the top 20 solar panel manufacturers in the world, aiding in informed choices for a

Get Price

The current state of U.S. polysilicon production – pv

U.S. solar module manufacturing has grown fivefold since supportive legislation passed in 2022. Over that time, 70 new solar and

Get Price

2024 World''s Top 20 Silicon Material/Wafer

On the first day of the conference, PVBL''s annual ranking of the Top 20 Global Silicon Material/Wafer Manufacturers was announced. Most of

Get Price

Solar panel manufacturers in the United States

A current list of U.S. solar panel manufacturers that produce solar panels for the traditional American residential, commercial and utility-scale markets.

Get Price

Solar Photovoltaic Manufacturing Basics

While some concentrating solar-thermal manufacturing exists, most solar manufacturing in the United States is related to photovoltaic (PV) systems. Those systems are comprised of PV

Get Price

Top 20 Solar Power System Manufacturers in the USA (2025)

Discover the leading 20 U.S. solar manufacturers driving clean energy in 2025. Explore company info, specialties, and contact details.

Get Price

The current state of U.S. polysilicon production – pv magazine

U.S. solar module manufacturing has grown fivefold since supportive legislation passed in 2022. Over that time, 70 new solar and energy storage manufacturing facilities have

Get Price

PowerFilm Solar

We design and manufacture custom solar cells, panels, and power solutions using proprietary thin-film or high-efficiency crystalline PV technology.

Get Price

Top 20 Solar Panel Manufacturers in the World

In this article, we will provide a comprehensive list of the top 20 solar panel manufacturers in the world, aiding in informed choices for a sustainable future.

Get Price

Top 5 American Solar Panel Manufacturers In 2025

Top 5 American solar panel manufacturers in 2025: A list of top U.S. solar panel manufacturers. Find the best companies that produce high-quality, American-made solar

Get Price

11 Best Solar Panel Manufacturers

Compare top solar panels for 2024: JinkoSolar, JA Solar, and more. Assess efficiency, warranty, and price to choose the best.

Get Price

Solar panel manufacturers in the United States

A current list of U.S. solar panel manufacturers that produce solar panels for the traditional American residential, commercial and utility-scale

Get Price

Manufacturing Technologies

With our cutting-edge manufacturing capabilities, we can produce resilient and high-quality, single-crystal ingots that serve as the foundation for top-tier solar

Get Price

PV Module Certifications: A Guide to IEC & UL

Navigate the world of PV module manufacturing standards. Our guide covers key IEC and UL certifications required for product quality, safety,

Get Price

Which companies are making solar panels in the United States?

As it stands today, U.S. solar panel manufacturing consists only of module assembly in the crystalline silicon space, but the promised credits could rebuild the domestic

Get Price

BIPV Supplier | Photovoltaic (BIPV) Solutions | Gain

BIPV Photovoltaic BIPV Solution As a BIPV manufacturer, we offer Building Integrated Photovoltaic (BIPV) solutions that integrate photovoltaic elements

Get Price

List of photovoltaics companies

Photovoltaics companies include PV capital equipment producers, cell manufacturers, panel manufacturers and installers. The list does not include silicon manufacturing companies.

Get Price

Solar Panel Types Explained: Mono, Poly, & Thin-Film Tech

The solar panel market has seen tremendous growth in recent years, with an increased variety of panel types and manufacturers now available to choose from. In this

Get Price

The current state of U.S. polysilicon production – pv

Despite rising tariffs on imports and a looming U.S. Department of Commerce investigation, American solar-grade polysilicon production is

Get Price

What is the Manufacturing Process of Solar Panels?

The manufacturing process of solar panels primarily involves silicon cell production, panel assembly, and quality assurance. Starting from silicon crystals, the process

Get Price

Oxford PV

Oxford PV - Solar that takes you further. Oxford PV is a leading innovator and manufacturer in the field of Perovskite-based PV, with over a decade of

Get Price

Solar Photovoltaic Manufacturing Basics

While some concentrating solar-thermal manufacturing exists, most solar manufacturing in the United States is related to photovoltaic (PV) systems.

Get Price

The Solar Panel Manufacturing Process

Discover the intricate processes in solar panel manufacturing, from silicon purification to the final assembly and testing.

Get Price

Executive summary – Solar PV Global Supply Chains

Today, China''s share in all the manufacturing stages of solar panels (such as polysilicon, ingots, wafers, cells and modules) exceeds 80%. This is more than

Get Price

6 FAQs about [Photovoltaic silicon panel manufacturer]

How are silicon solar panels made?

A traditional silicon solar panel requires polysilicon, which is then shaped into silicon ingots, which are then cut into silicon wafers, which turn into silicon solar cells that are finally assembled into silicon solar panels.

Where are the top ten polysilicon & solar module manufacturers?

According to EnergyTrend, the 2011 global top ten polysilicon, solar cell and solar module manufacturers by capacity were found in countries including People's Republic of China, United States, Taiwan, Germany, Japan, and Korea.

Is Panasonic a good company to buy solar panels?

While Panasonic is well-known for manufacturing electronic devices like smartphones, cameras, and air-conditioners, it is also a producer of solar panels. The PV modules from Panasonic are recognized for their exceptional reliability. Among their best series is the 330N HIT, consisting of 96 solar cells and boasting a 19.7% efficiency rate.

Will US solar-grade polysilicon production keep pace with domestic PV supply chain?

Despite rising tariffs on imports and a looming U.S. Department of Commerce investigation, American solar-grade polysilicon production is expected to keep pace with the growth of the domestic PV supply chain. From pv magazine 03/25 U.S. solar module manufacturing has grown fivefold since supportive legislation passed in 2022.

Are solar panels a sustainable solution for commercial trucking?

Solar power is emerging as a transformative solution, offering a sustainable way to address these challenges across various systems within a truck. This blog overviews five key areas where solar panels make a tangible impact—offering savings, reliability, and efficiency. What's The Return on Investment for a Commercial Trucking Solar Solution?

Will US polysilicon be a'made in America' Solar System?

Module assembly from imported cells has been the initial focus, but fully “made in America” solar would require U.S. polysilicon. The nation has only two operational polysilicon sites today, but President Donald Trump’s willingness to use tariffs, plus anticipated rising demand for PV, could make polysilicon production an attractive proposition.

More related information

-

Photovoltaic silicon solar panel manufacturer

Photovoltaic silicon solar panel manufacturer

-

Photovoltaic silicon panel manufacturer

Photovoltaic silicon panel manufacturer

-

Photovoltaic crystalline silicon panel manufacturer

Photovoltaic crystalline silicon panel manufacturer

-

Polycrystalline silicon photovoltaic panel manufacturer

Polycrystalline silicon photovoltaic panel manufacturer

-

Central Asia Photovoltaic Panel Manufacturer

Central Asia Photovoltaic Panel Manufacturer

-

Polish rooftop photovoltaic panel manufacturer

Polish rooftop photovoltaic panel manufacturer

-

Mali s new photovoltaic panel manufacturer

Mali s new photovoltaic panel manufacturer

-

Mexico balcony solar photovoltaic panel manufacturer

Mexico balcony solar photovoltaic panel manufacturer

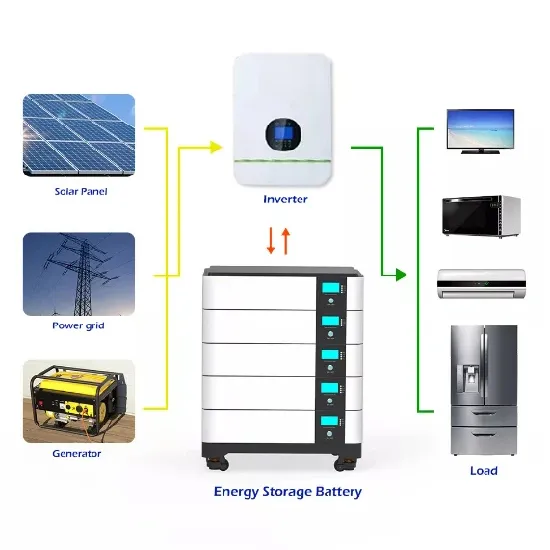

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

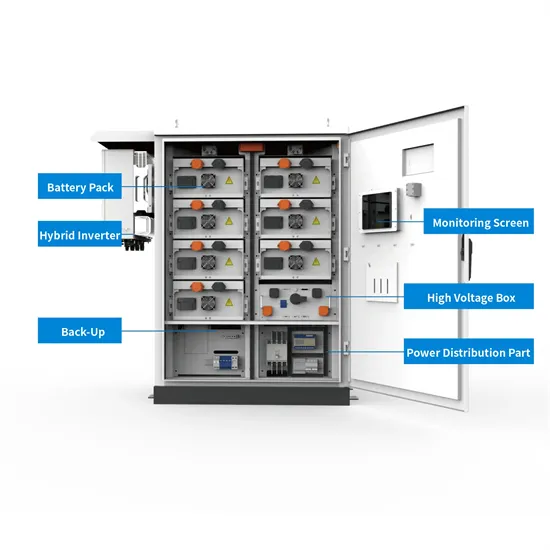

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.