Guide to Battery Cabinets for Lithium-Ion Batteries: 6

3. Safe Charging Mechanism for Lithium-Ion Batteries If the cabinet will be used for charging lithium-ion batteries, ensure it''s specifically

Get Price

battery cabinet production, protect the batteries

Dear friend, this video has show how to produce the battery cabinet. more step are control by computer, it can ensure the correct size for the battery cabinet. if you has any question about

Get Price

Lithium battery energy storage cabinet production tutorial

This article discusses cell production of post-lithium-ion batteries by examining the industrial-scale manufacturing of Li ion batteries, sodium ion batteries, lithium sulfur...

Get Price

How AZE Systems Manufactures BESS Battery Energy Storage Cabinets

Manufacturing a BESS cabinet requires a combination of advanced engineering, precise manufacturing, and rigorous testing. By following the steps outlined above, you can

Get Price

Battery Energy Storage Cabinet Construction Process: From

Let''s be real - when most people hear "battery energy storage cabinet construction process," they picture workers bolting together metal panels like IKEA furniture on steroids. But here''s the

Get Price

Battery cabinet production workshop process flow

production of a cabinet part for LG Electronics. The process involves 14 steps: 1) receiving materials, 2) incoming inspection, 3) storage, 4) three press steps including forming, punching

Get Price

A road map for battery energy storage system execution

Integration of energy storage products begins at the cell level and manufacturers have adopted different approaches toward modular design of

Get Price

Battery Cabinets Manufacturer

OGS Power production high quality "Battery Cabinets Manufacturer" by affordable prices besides free technical service and installation.

Get Price

Complete Guide for Battery Enclosure

Everyone wants a safe, durable, high quality and secure battery enclosure. However, finding the right information about these battery boxes or cabinet is always a

Get Price

Energy storage battery cabinet battery cluster production line

As a professional manufacturer in China, produces both energy storage cabinets and battery cell in-house, ensuring full quality control across the entire production process.

Get Price

Battery Plant Design | Architecture and Engineering Firm

We provide full-service planning, design, and engineering solutions for every moment of the battery manufacturing lifecycle. Our interdisciplinary team rises

Get Price

How AZE Systems Manufactures BESS Battery Energy Storage

Manufacturing a BESS cabinet requires a combination of advanced engineering, precise manufacturing, and rigorous testing. By following the steps outlined above, you can

Get Price

Explosion-proof measures for battery cabinets during production

EV Battery Cleanrooms & Equipment for New Facility Builds Explosion-proof, fire-rated components & workstations ; EV Battery Manufacturing Solutions Cleanrooms & Dry Rooms

Get Price

Battery Cabinets vs. Battery Racks

On battery cabinets, the disconnect switch should be mounted in the door to allow the battery to be disconnected from the UPS before the door

Get Price

Planning your U.S. Battery Manufacturing Plant

SSOE''s experience extends throughout the battery lifecycle, from raw materials to recycling and includes work at some of the world''s largest battery manufacturing facilities.

Get Price

Production Flow Chart of Energy Storage Battery Cabinets: A

Production Flow Chart of Energy Storage Battery Cabinets: A Step-by-Step Guide for Manufacturers

Get Price

Battery Enclosures

Find here Battery Enclosures, Battery Cabinet manufacturers, suppliers & exporters in India. Get contact details & address of companies manufacturing

Get Price

ESTEL Outdoor Battery Cabinets What You Need to Know

Choose the best outdoor battery cabinet with weatherproof design, security features, and climate control to protect your batteries and ensure reliable performance.

Get Price

Clean/Dry Rooms for Lithium Ion Battery Manufacturing

In a lithium-ion battery, you''ll find pressurized containers that house a coil of metal and a flammable, lithium-containing liquid. The manufacturing process creates tiny pieces of metal

Get Price

Lithium Ion Battery Charging Cabinets

Justrite''s Lithium-Ion battery Charging Safety Cabinet is engineered to charge and store lithium batteries safely. Made with a proprietary 9-layer

Get Price

National Blueprint for Lithium Batteries 2021-2030

This National Blueprint for Lithium Batteries, developed by the Federal Consortium for Advanced Batteries will help guide investments to develop a domestic lithium-battery manufacturing

Get Price

Battery cabinet production cost accounting

The OmniPower stackable battery cabinets are strong, locally-manufactured powder-coated steel units that ensure your battery bank is safely enclosed while adding great aesthetic appeal to

Get Price

A road map for battery energy storage system execution

Integration of energy storage products begins at the cell level and manufacturers have adopted different approaches toward modular design of internal systems, all with the goal

Get Price

Battery Manufacturing Process: Materials, Production & Test

The battery manufacturing process is a complex sequence of steps transforming raw materials into functional, reliable energy storage units. This guide covers the entire process,

Get Price

Battery Plant Design Do''s and Don''ts

Establishing an EV battery manufacturing facility during this industrial and economic shift poses unique challenges that require careful consideration and strategic thinking.

Get Price

What Are the 9 Operating Costs of Lithium Ion Battery

Discover the nine key operating costs in lithium-ion battery production. Get actionable insights to optimize expenses and boost efficiency.

Get Price

More related information

-

Site Energy Battery Cabinet Promotion Strategy Plan

Site Energy Battery Cabinet Promotion Strategy Plan

-

Outdoor battery cabinet foundation production ESS power base station

Outdoor battery cabinet foundation production ESS power base station

-

Energy storage cabinet battery production emergency power supply site

Energy storage cabinet battery production emergency power supply site

-

Ranking of Armenian outdoor communication battery cabinet production companies

Ranking of Armenian outdoor communication battery cabinet production companies

-

5g Network Battery Cabinet Production

5g Network Battery Cabinet Production

-

How much does battery cabinet production equipment cost

How much does battery cabinet production equipment cost

-

Battery cabinet frame production integrated system

Battery cabinet frame production integrated system

-

Latvian energy storage cabinet battery production base

Latvian energy storage cabinet battery production base

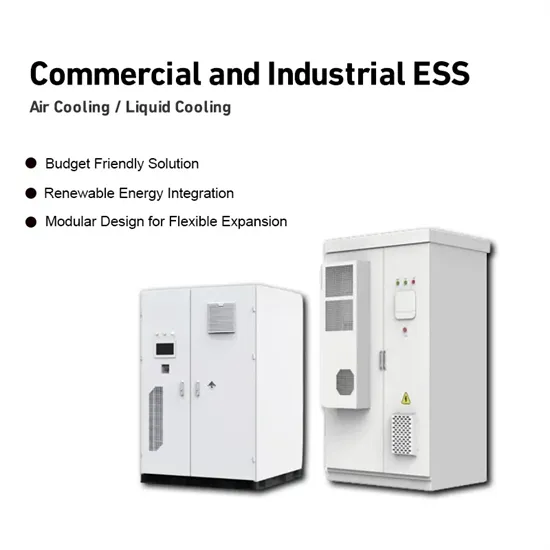

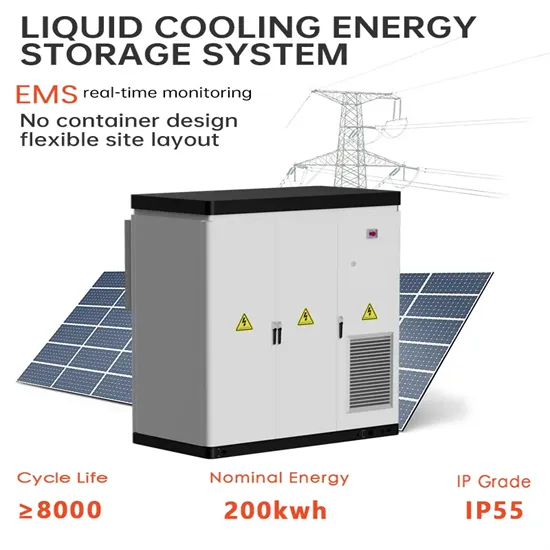

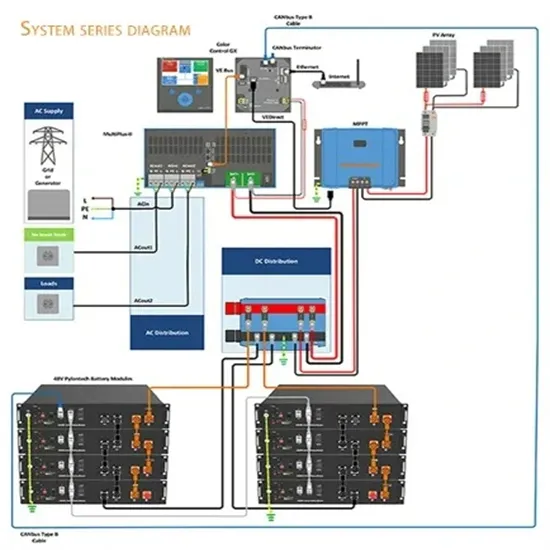

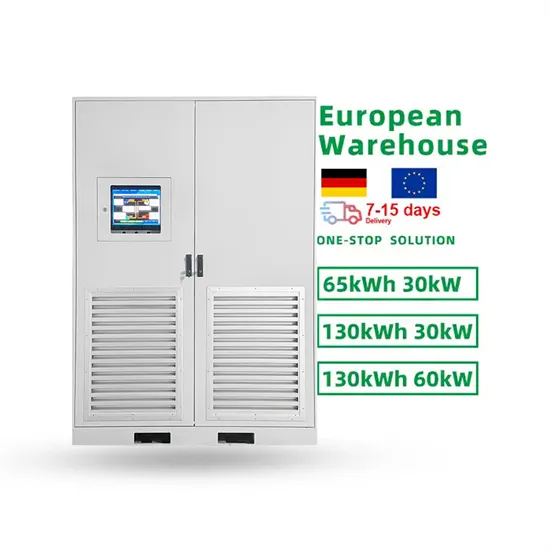

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.