Offshore wind farms critical comms TETRA Semco Maritime

In addition to the need to ensure workers'' safety, reliable communications are required due to the way in which operations are highly weather dependent – according to

Get Price

How digitalization and private wireless are increasing wind farm safety

Each base station provides secure, high bandwidth connectivity, which can reliably interact with turbines, workers and vessels many miles away. This ensures that the entire wind

Get Price

Wind Solar Hybrid Power System for the Communication Base Station

In conclusion, it''s more eco-friendly and economic to construct a wind solar hybrid power system for the communication base station cause solar and wind is sufficient here.

Get Price

Wind turbine safety precautions for wind energy workers

In the dynamic and ever-evolving realm of renewable energy, wind turbines stand as colossal icons of progress towards a more electrified and carbon-free society. Harnessing

Get Price

Research on Offshore Wind Power Communication System

Result After the completion of the 5G communication system based on PTN+ integrated small base station, IP transmission based on optical transmission, supporting

Get Price

Enhancing Communication Tower Safety NAVIS Anemometers

Learn how NAVIS wind anemometers ensure safety on communication towers by providing real-time wind data during maintenance and construction.

Get Price

Offshore wind farms critical comms TETRA Semco

MoWhile critical communications deployments in the public safety sector are often driven by a combination of technology change and existing

Get Price

Critical Communication Solutions for Offshore wind

Working in the offshore wind industry means working in an extreme environment with large assets spread over a wide area. In order to meet high HSE requirements, warn and localize workers

Get Price

5G Communication Base Stations Participating in Demand

However, pumped storage power stations and grid-side energy storage facilities, which are flexible peak-shaving resources, have relatively high investment and operation

Get Price

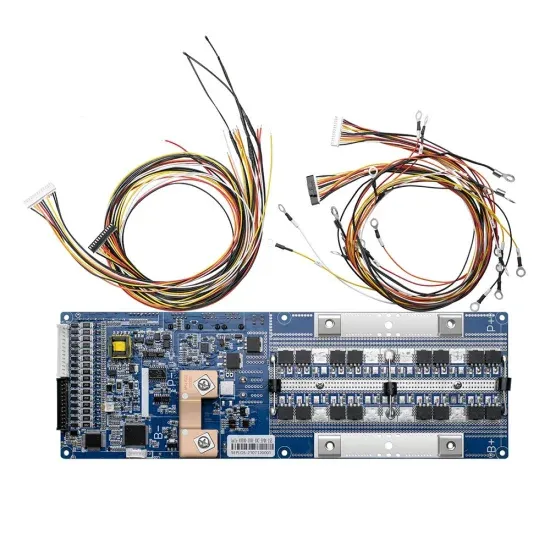

Communication Base Station Backup Power LiFePO4 Supplier

Why LiFePO4 battery as a backup power supply for the communications industry? 1.The new requirements in the field of communications storage. For a long period of time,

Get Price

(PDF) Small windturbines for telecom base stations

The presentation will give attention to the requirements on using windenergy as an energy source for powering mobile phone base stations.

Get Price

Research on Offshore Wind Power Communication System

In view of the special needs of the communication system, a communication system scheme for offshore wind farms based on 5G technology is proposed.

Get Price

Post-earthquake functional state assessment of communication base

The method considers the dependence between the equipment and its hosting building structure, and the impact of power outages. This model produces seismic functional

Get Price

Offshore wind farms critical comms TETRA Semco

In addition to the need to ensure workers'' safety, reliable communications are required due to the way in which operations are highly

Get Price

Low-Carbon Sustainable Development of 5G Base Stations in China

As 5G serves as the foundation for the construction of new infrastructure, China, as the world leader in 5G base station construction, has already built over 1.4 million 5G base

Get Price

Offshore wind Offshore wind: Communication

We establish a reliable and redundant TETRA connection between all vessels, turbines, the offshore substation, the onshore office and helicopters to enable direct calls.

Get Price

3 Comms Considerations for Offshore Wind Farms

This blog focuses on 3 comms considerations for offshore wind farms, from wind turbines to O&M and VHF marine vessels. Find out more.

Get Price

Risk assessment and management in the offshore wind power

The G+ 2021 incident data report, published by G+ Global Offshore Wind Health and Safety Organization (2021), identifies lifting operations as the primary cause of incidents

Get Price

Wind-turbine construction safety tips | Wind Systems Magazine

In conclusion, wind-turbine construction and demolition are inherently hazardous operations that require a high level of safety and caution. By following these 10 tips, employers

Get Price

Offshore Wind Electrical Safety Standards Harmonization

As such, BSEE created a comparison of U.S. versus international electrical safety standards to assist BSEE/BOEM engineers in performing a comprehensive assessment of project electrical

Get Price

Wind-turbine construction safety tips | Wind Systems

In conclusion, wind-turbine construction and demolition are inherently hazardous operations that require a high level of safety and caution.

Get Price

Title

In Poland, where the maximum permissible power density value is 0.1 W/m 2 at relevant base station frequencies, measurements of electromagnetic fields (EMF) in the surrounds of 20

Get Price

(PDF) Small windturbines for telecom base stations

The presentation will give attention to the requirements on using windenergy as an energy source for powering mobile phone base stations.

Get Price

Identifying and Avoiding Radio Frequency Interference for

This paper describes how these problems can be identified and avoided during the design and site selection of the wind power facilities through analysis and measurement methods used

Get Price

WINDExchange: Wind Energy Projects and Safety

Wind Energy Projects and Safety As a source of abundant energy, wind energy offers many advantages. However, as with any energy generation facility,

Get Price

Cell Phone Tower Management and Base Station Safety

ABSTRACT In mobile communication base transceiver station plays important role. Each mobile communication base station consist of different units like power generation and distribution

Get Price

6 FAQs about [Safety of wind power construction projects for communication base stations]

Can wind energy be used to power mobile phone base stations?

Worldwide thousands of base stations provide relaying mobile phone signals. Every off-grid base station has a diesel generator up to 4 kW to provide electricity for the electronic equipment involved. The presentation will give attention to the requirements on using windenergy as an energy source for powering mobile phone base stations.

Are wind-turbine construction and demolition safe?

By regularly reviewing and updating safety procedures, employers can help identify and eliminate hazards and ensure workers are protected from harm. In conclusion, wind-turbine construction and demolition are inherently hazardous operations that require a high level of safety and caution.

Do wind turbine workers need safety training?

All workers involved in wind-turbine construction and demolition should be trained on the specific hazards of the job, including fall protection, electrical safety, and heavy-machinery operation. This training should be ongoing to ensure that workers are up-to-date on the latest safety guidelines and procedures.

Do you need a risk assessment before building a wind turbine?

Before beginning any construction or demolition of wind turbines, it is crucial to conduct a thorough risk assessment. Identify the potential hazards, such as falls, electrical hazards, and heavy machinery operation, and determine the likelihood and severity of injury or harm.

What is a hazard in wind-turbine construction & demolition?

Electricity is another major hazard in wind-turbine construction and demolition. To protect workers from electrical hazards, employers should ensure all electrical equipment is properly grounded, and electrical panels, switches, and wiring are in good working condition.

Why is personal protective equipment important in wind-turbine construction & demolition?

Personal protective equipment (PPE) is essential for protecting workers from a variety of hazards, including falls, falling objects, electrical hazards, and more. (Courtesy: Shutterstock) Electricity is another major hazard in wind-turbine construction and demolition.

More related information

-

Wind power construction of communication base stations in Côte d Ivoire

Wind power construction of communication base stations in Côte d Ivoire

-

Construction cost of wind power equipment for communication base stations

Construction cost of wind power equipment for communication base stations

-

What are the wind power projects for communication base stations in Sao Tome and Principe

What are the wind power projects for communication base stations in Sao Tome and Principe

-

Investment plan for wind power construction of communication base stations

Investment plan for wind power construction of communication base stations

-

Battery direction for wind power in communication base stations

Battery direction for wind power in communication base stations

-

The gap between China and the United States in wind and solar hybrid power supply for communication base stations

The gap between China and the United States in wind and solar hybrid power supply for communication base stations

-

Lithium batteries for communication base stations with wind power

Lithium batteries for communication base stations with wind power

-

What are the wind power expansion units for communication base stations

What are the wind power expansion units for communication base stations

Commercial & Industrial Solar Storage Market Growth

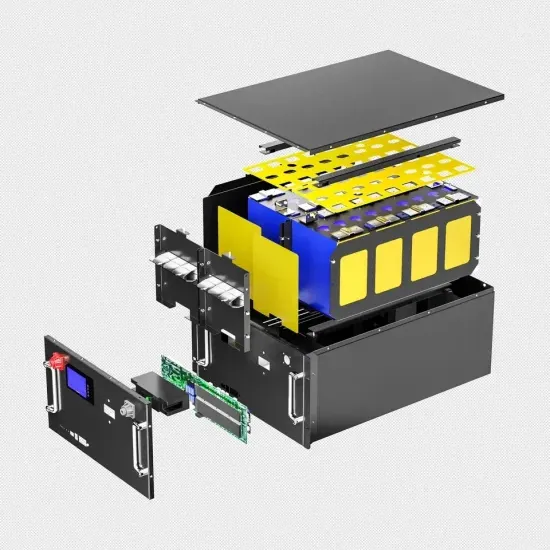

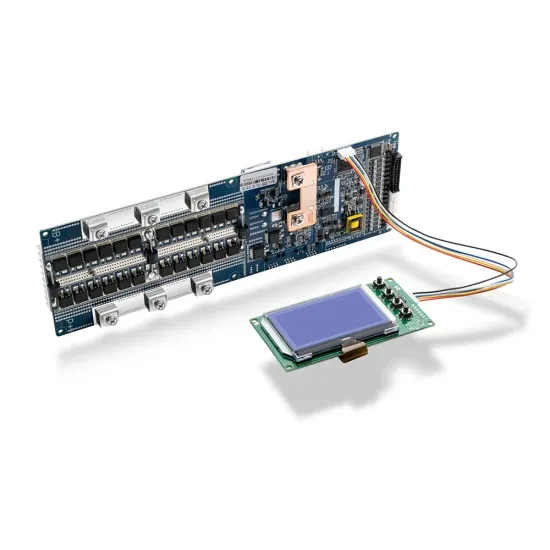

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.