Closed-Loop Communication: What is it, and why it is

Why is Closed-Loop Communication Important to Off-Grid Solar Battery System? Closed-Loop communication between the BMSs and

Get Price

Bad, Better, Best: Battery-Inverter Communications

In this article, we will compare basic and advanced battery communication, discuss the challenge of ''good'' inverter-battery

Get Price

Pytes Communication Cable 3.5 meter for battery to

Pytes Communication Cable 3.5 meter for battery to inverter SKU Pytes Communication Cable Be the first to review this product

Get Price

Battery Communication: Closed vs. Open-Loop Communications

A lithium battery in closed-loop communication with a compatible inverter/charger can take full advantage of available capacity with fewer moving parts and a simplified

Get Price

Bad, Better, Best: Battery-Inverter Communications & Compatibility

In this article, we will compare basic and advanced battery communication, discuss the challenge of ''good'' inverter-battery communication, and what happens when it''s

Get Price

Hybrid Inverter and Lithium Batteries: Setup Guide

In this guide, we will take you through the step-by-step process of setting up communication between lithium batteries and a hybrid inverter. We will delve

Get Price

Understanding BMS and its Integration with Solar

System Optimization: The communication between the BMS and the solar inverter allows for system optimization. With access to real-time data

Get Price

How Does an Inverter Communicate with a Battery?

How Does an Inverter Communicate with a Battery? An inverter communicates with a battery through a series of electrical signals and protocols that manage the flow of energy.

Get Price

How Does an Inverter Communicate with a Battery?

An inverter communicates with a battery through a series of electrical signals and protocols that manage the flow of energy. This communication ensures that the inverter can

Get Price

Inverter to battery communication? Important or nice to have?

We get a ton of battery communication and battery-inverter compatibility questions and have turned those into a blog series that''s intended to be a resource for installers,

Get Price

Battery and Inverter communication

Depends on the inverter you use I have seen inverters that only utilize CAN or RS485 but others that can use both. Would you mind clarifying

Get Price

Battery-Inverter Communications Watch the video and

Battery-Inverter Communications🔗 🎬Watch the video and see how to establish BMS communication between Anern''s lithium battery and the inverter! If you want to know anything else, feel free

Get Price

Felicity Lithium Battery BMS Communication Guide

Felicity Solar Lithium battery pairing with Deye/SunSynk, Growatt SPF Series and Voltronic Power (Kodak/RCT/Mecer) Axpert and InfiniSolar

Get Price

Practical Guide to Cross-Brand Inverter and Lithium Battery BMS

In this article, we''ll guide you step by step on how to connect a Sunflx battery to an inverter to make sure the BMS communicates correctly.

Get Price

Why lithium ion battery need communications

However, unlike gel or AGM batteries, lithium-ion and LiFePO4 batteries require communication with the inverter for optimal performance. But why is this communication

Get Price

5. Communication wiring

Communication cables between multiple inverters or inverter/charger units to create a parallel and/or 3-phase system. Communication cables to control equipment, for example, between a

Get Price

Pytes Battery-to-Inverter Communication Cable 3.5m

Founded in 2003, Inverters R Us is one of the largest Victron suppliers in the world. We are known for our system designs, technical/pre & post sales

Get Price

How Do Inverters Communicate — EASUN POWER Official Store

Inverters communicate through a variety of methods to optimize energy management across different settings. This discussion explores the key communication

Get Price

Why lithium ion battery need communications

However, unlike gel or AGM batteries, lithium-ion and LiFePO4 batteries require communication with the inverter for optimal performance. But

Get Price

RS485 Communications Troubleshooting Guide

485 wires between each two devices in the chain. Repeat this un inverter, while inverters 2 and 3 are followers. RS485 is wired to B, A, and Then three new wires connected in the same B, A,

Get Price

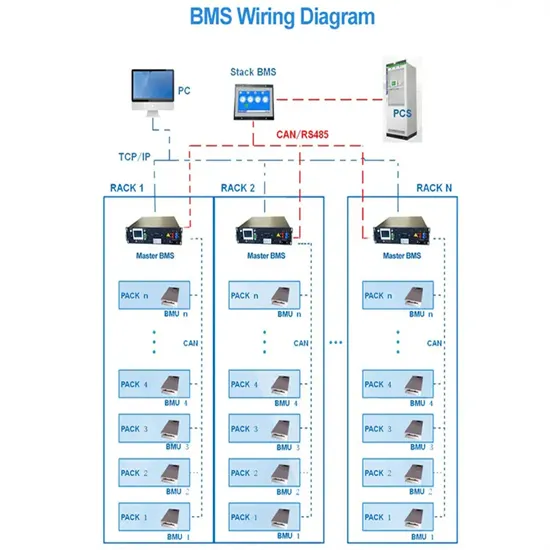

A Guide to BMS Communication Protocols

Communication protocols enable real-time monitoring, control, and optimization of battery performance. These BMS communication protocols

Get Price

What is BMS Communication? Do You Need it?

6 days ago· BMS communication enables lithium batteries to share real-time data about themselves with other devices in an off-grid or backup power

Get Price

Sol-Ark Low Voltage Battery Integration Guide

805 S. Central Expressway Allen, TX 75013 (972) 575- 8875 Tech Support Mon-Fri: 7am-8pm CST Sat-Sun: 9am-5pm CST

Get Price

Battery Communication: Closed vs. Open-Loop

A lithium battery in closed-loop communication with a compatible inverter/charger can take full advantage of available capacity with fewer

Get Price

Hybrid Inverter and Lithium Batteries: Setup Guide and Best

In this guide, we will take you through the step-by-step process of setting up communication between lithium batteries and a hybrid inverter. We will delve into the technical intricacies,

Get Price

Are BMS RS485 & CAN communications generic or battery/inverter

Many BMS and Inverters provide for selection (programmable) of a common protocol. Just review your inverter manual for the battery type and communication settings.

Get Price

What is BMS Communication? Do You Need it?

6 days ago· BMS communication enables lithium batteries to share real-time data about themselves with other devices in an off-grid or backup power system. The most common use

Get Price

Lithium battery BMS communication

Effective BMS communication ensures that the inverter adjusts its charging and discharging rate based on the battery''s current state. When these systems work in tandem, it leads to better

Get Price

6 FAQs about [Battery Inverter Communication]

How does a battery-inverter system work?

In a power system with closed-loop communication, the inverter, solar charge controllers, and other components do not control the battery. Instead, the battery informs the decisions made by everything else in the system. The performance of any battery-inverter combination depends on how effectively the battery can fulfill this role.

How to connect a battery to an inverter?

Power Cables: Use appropriately sized power cables to connect the battery to the inverter. The cable size should be chosen based on the current rating of the system to minimize power loss and avoid overheating. Communication Cables: For communication, use the cables specified by the manufacturers.

What makes a good battery-inverter combination?

The performance of any battery-inverter combination depends on how effectively the battery can fulfill this role. For the battery to receive what it needs and for the system to operate at peak performance, these control messages must be accurate and well-understood by the rest of the system. As you will see, this is not always a given.

Are hybrid inverters compatible with lithium batteries?

Compatibility is the first and foremost consideration when setting up communication between a lithium battery and a hybrid inverter. Not all inverters are compatible with all lithium batteries. Therefore, it is crucial to ensure that the inverter you choose is designed to work with the specific type of lithium battery you plan to use.

How does a hybrid inverter work?

The efficient operation of a hybrid inverter relies heavily on seamless communication with lithium batteries. Properly establishing this communication ensures that your energy storage system performs optimally, maximizes battery life, and maintains system reliability.

Are budget battery companies compatible with inverters?

Most budget battery companies don’t have support from the inverter companies they claim compatibility with. Rather, they reverse-engineer communication protocols established by officially supported brands or simply buy and incorporate their BMS boards.

More related information

-

Huawei communication base station inverter battery

Huawei communication base station inverter battery

-

Is the battery of the communication base station inverter harmful

Is the battery of the communication base station inverter harmful

-

Battery Portable Inverter

Battery Portable Inverter

-

Specialized battery for communication base stations

Specialized battery for communication base stations

-

Flow battery construction for communication base stations in Switzerland

Flow battery construction for communication base stations in Switzerland

-

Kazakhstan lithium battery inverter

Kazakhstan lithium battery inverter

-

Communication base station flow battery commissioning quota

Communication base station flow battery commissioning quota

-

Is there power in the negative electrode of the energy storage battery of the communication base station

Is there power in the negative electrode of the energy storage battery of the communication base station

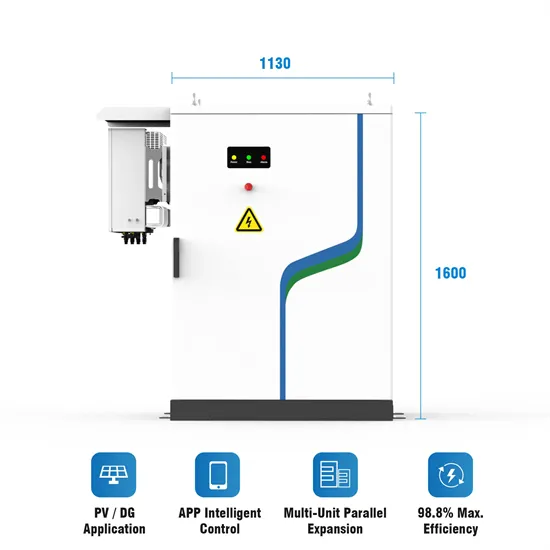

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.