Every Thing You Should Know About Optical Crystal

Optical crystal processing involves precision cutting, polishing and coating of crystal materials to meet the high requirements for precision and surface quality of optical components.

Get Price

Reversible single crystal-to-single crystal double [2+2]

Here, the authors report an electroactive framework that exhibits a reversible single crystal-to-single crystal double [2+2] photocyclisation, leading to property changes.

Get Price

Watch Crystals, Domed, Double Domed and Atomic Structure

We hear lots of people talk about the crystal, whether it is domed, double domed or just flat. But then there is the added complication of the material the crystal is made from.

Get Price

Stacked high-resistance layer induced dual-focal liquid crystal

As a wide-bandgap semiconductor, ZnO offers high resistivity, enabling effective electric field control in liquid crystal devices, which is critical for achieving uniform liquid crystal

Get Price

Single-Crystal Fibers

Single-crystal fibers are a fascinating and innovative component in the field of photonics, offering unique properties for various optical applications. This blog

Get Price

Watch Crystals, Domed, Double Domed and Atomic Structure

There are a number of real benefits of a double domed crystal and that is why they are particularly popular on many high end and luxury watches. Just for clarity though, let''s take

Get Price

Watch Crystals: ''Clearly'' an Interesting Subject.

Double-domed crystals are also domed on the underside, and while they look identical to the single-domed crystal, they produce little

Get Price

Watch Crystals, Domed, Double Domed and Atomic Structure

At the core of these developments lie single-crystal silicon solar panels, renowned for their exceptional energy conversion rates. These panels are made from a single continuous

Get Price

An In-depth Analysis of Optical Crystals: Single Crystal vs

Growing a large, flawless single crystal requires specialized equipment, controlled environments, and often, rare raw materials. This makes the production of single crystals a cost-intensive

Get Price

Single Crystal Casting: Advancing Durability in High

Discover the advantages of single crystal casting for high-performance superalloy components. Learn about the manufacturing process, typical materials,

Get Price

twin crystal ultrasonic probes?

electronic components and industrial products; as well as for a wide range of applications, such as automotive inspection, aerospace / space, 3D metal printing and

Get Price

A comprehensive review on polymer single crystals—From

Polymer single crystals and correlated crystalline structures are reviewed by emphasizing the last 10–20 years of research on fundamental concepts, single crystal

Get Price

An In-depth Analysis of Optical Crystals: Single

Growing a large, flawless single crystal requires specialized equipment, controlled environments, and often, rare raw materials. This makes the production of

Get Price

Advances in Single-Crystal Films: Synergistic Insights from

Semiconductor single-crystal thin films are crucial for the advancement of high-performance optoelectronic devices. Despite significant progress in fabricating perovskite and

Get Price

Monatomic glass formation through competing order balance

2 days ago· These findings clarify the role of local icosahedral order in glass formation, crystallisation, and quasi-crystallisation of monatomic metals, with potential extrapolation to

Get Price

Crystal

Crystal - Structure, Lattice, Symmetry: Crystals can be grown under moderate conditions from all 92 naturally occurring elements except helium,

Get Price

How many watts can a single crystal double glass hard plate

At the core of these developments lie single-crystal silicon solar panels, renowned for their exceptional energy conversion rates. These panels are made from a single continuous

Get Price

Introduction To Single Crystal,polycrystalline,and Amorphous

For example, in the field of optics, single crystal materials are used to produce high-precision optical lenses and laser devices. In addition, single crystal alloys are widely used in

Get Price

A universal strategy toward two-component organic-inorganic

In this work, we developed a universal strategy toward two- component OIMH glass, which can expand the material systems of OIMH glasses.

Get Price

Nanostructure formation of double-clad Cr4+:YAG crystal fiber

The microstructures of double-clad Cr 4+:YAG crystal fibers grown using a co-drawing laser-heated pedestal growth method were studied by high-resolution transmission

Get Price

A universal strategy toward two-component organic-inorganic

The development of melt- quenched organic- inorganic metal halide (OIMH) glasses is hampered by the scarcity of suitable organic molten salts and low luminescence

Get Price

Single crystal

The field of photodriven transformation can also be involved with single crystals with something called single-crystal-to-single-crystal (SCSC) transformations.

Get Price

Giant single-crystal-to-single-crystal transformations associated

However, the development of single crystals with super-adaptive crystal lattices capable of huge and reversible structural change remains a great challenge.

Get Price

The Power of One: Single crystals provide clarity

Optical float-zone technique uses focused, high-intensity light to create single crystals, particularly those containing metal oxides. According to associate scientist Yong Liu,

Get Price

Advances in Single-Crystal Fibers and Thin Rods Grown by

Abstract: Single-crystal fibers are an intermediate between laser crystals and doped glass fibers. They have the advantages of both guiding laser light and matching the efficiencies found in

Get Price

Single Crystal Casting: Advancing Durability in High-Temperature

Discover the advantages of single crystal casting for high-performance superalloy components. Learn about the manufacturing process, typical materials, prototyping methods, testing

Get Price

Education

A mineral glass watch crystal is hardened glass (Seiko name – Hardlex), which is much more scratch resistant than acrylic, but significantly less than sapphire.

Get Price

6 FAQs about [High crystal components and single crystal double glass]

What is a single domed crystal?

This is the process used in most mass produced watches. Single domed crystals are generally flat on the base (closest to the watch face) and domed on top. Depending on how the exact geometry is implemented it can distort the view of the watch face. This can be used to good effect to magnify the view and can be useful in dive watches.

What is a high-purity single crystal?

A high-purity (99.999 %) tantalum single crystal, made by the floating zone process, some single crystalline fragments of tantalum, and a high-purity (99.99% = 4N) 1 cm 3 tantalum cube for comparison. Monocrystalline silicon used in the fabrication of semiconductors and photovoltaics is the greatest use of single-crystal technology today.

What is the internal structure of single crystal optical crystals?

That’s what the internal structure of single crystal optical crystals resembles. In these materials, the crystal lattice, which is the repetitive pattern of atoms, extends uniformly across the entire specimen. There are no grain boundaries, which are typically areas where different crystal structures meet, interrupting this orderly array.

What is a single crystal optical crystal?

However, when delved deeper into their characteristics and use-cases, the distinction becomes much clearer, underscoring the importance of making an informed choice based on specific requirements. Single crystal optical crystals, as the name suggests, are an epitome of orderliness at the atomic level.

Which optical crystal is best for microscopy?

The unique attributes of both single and polycrystalline optical crystals make them suited for specific applications. Single crystal optical crystals, with their unparalleled clarity and consistency, are the top choice for: High-resolution microscopy: Precision and clarity are of the essence here.

What is a single crystal?

In materials science, a single crystal (or single-crystal solid or monocrystalline solid) is a material in which the crystal lattice of the entire sample is continuous and unbroken to the edges of the sample, with no grain boundaries.

More related information

-

Heat resistance of single crystal double glass photovoltaic panels

Heat resistance of single crystal double glass photovoltaic panels

-

Fireproof double glass components

Fireproof double glass components

-

Single crystal perc72 panel type components

Single crystal perc72 panel type components

-

Photovoltaic panels with high efficiency and single crystal

Photovoltaic panels with high efficiency and single crystal

-

What is a single crystal PERC module

What is a single crystal PERC module

-

Single glass photovoltaic module price

Single glass photovoltaic module price

-

Photovoltaic panel single crystal size

Photovoltaic panel single crystal size

-

Guinea single glass photovoltaic curtain wall customization

Guinea single glass photovoltaic curtain wall customization

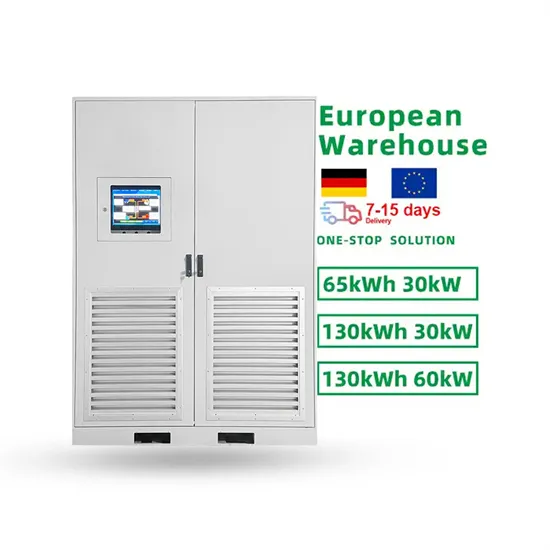

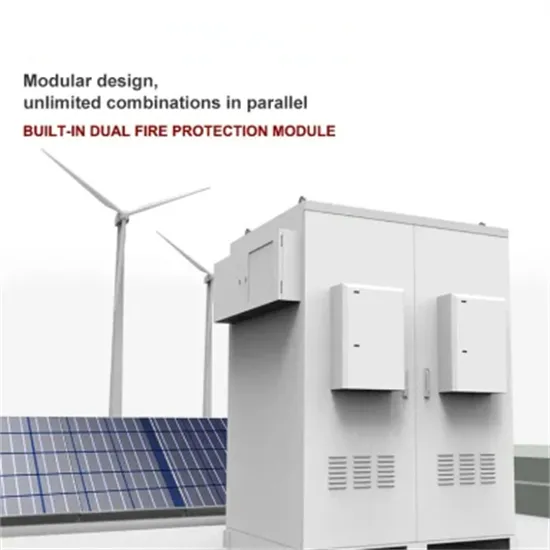

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

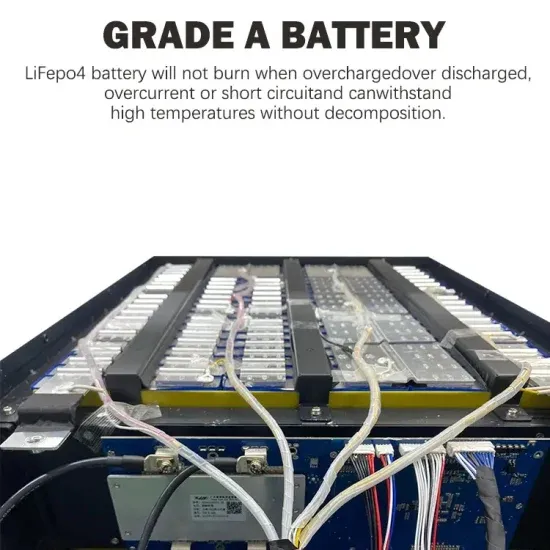

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.