The development of a techno-economic model for the

After determining the size and capacities of different components, we developed the cost functions for individual pieces of equipment to determine techno-economic performance

Get Price

Flywheel energy storage system price per KW

The steel rotor flywheel has a lower capital cost and levelized cost of storage. The costs of composite and steel rotor flywheels are $190 and $146/MWh,respectively. Flywheel energy

Get Price

Enhancing vehicular performance with flywheel energy storage

Flywheel Energy Storage Systems (FESS) are a pivotal innovation in vehicular technology, offering significant advancements in enhancing performance in vehicular

Get Price

REVIEW OF FLYWHEEL ENERGY STORAGE SYSTEM

And main factors like total energy losses, safety, cost control are discussed. Finally, application area of FES technology is presented including energy storage and attitude control in satellite,

Get Price

Flywheel Energy Storage System

Flywheel Energy Storage System (FESS) An introduction to mechanical flywheel technology for dispatchable generation in the renewable energy market Russell Hanna

Get Price

RotorVault Energy Storage Cost Analysis and Flywheel Price

Explore RotorVault''s cost-competitiveness and scalability. A comparative cost analysis with Battery and Flywheel Energy Storage Systems.

Get Price

Critical Review of Flywheel Energy Storage System

This review presents a detailed summary of the latest technologies used in flywheel energy storage systems (FESS). This paper covers the types

Get Price

Cost-Benefit Analysis of Flywheel Energy Storage in context of

Conducting detailed cost-benefit analyses for specific FES applications, such as frequency regulation or renewable energy integration. Investigating the impact of FES on grid

Get Price

How much does a flywheel energy storage system cost?

When evaluating the financial implications of flywheel energy storage, one must delve into various cost components involved in both the

Get Price

A Review of Flywheel Energy Storage System Technologies

Using energy storage technology can improve the stability and quality of the power grid. One such technology is flywheel energy storage systems (FESSs).

Get Price

How much does a flywheel energy storage system cost?

When evaluating the financial implications of flywheel energy storage, one must delve into various cost components involved in both the upfront investment and long-term

Get Price

Flywheel Energy Storage Costs Decoded: A 2024 Price Analysis

Industry experts predict 18-22% cost reductions by 2027 as 3D-printed rotors enter mass production. Imagine printing a Ferrari engine in your garage - that''s the level of disruption

Get Price

Flywheel Energy Storage for Residential Use: A Cost-Effective

Explore a cost-effective flywheel energy storage system (FESS) for homes. Design, materials, integration, and safety considerations are discussed.

Get Price

The Flywheel Energy Storage System: An Effective Solution to

Today the role of electricity is very important because it must meet the need for continuous power supply for all manufacturing industries and human social life. Moreover, the current production

Get Price

A review of flywheel energy storage systems: state of the art

The ex-isting energy storage systems use various technologies, including hydro-electricity, batteries, supercapacitors, thermal storage, energy storage flywheels,[2] and

Get Price

Flywheel energy storage systems: A critical review on

In this article, an overview of the FESS has been discussed concerning its background theory, structure with its associated components, characteristics, applications,

Get Price

$200 Million For Renewables-Friendly Flywheel Energy Storage

1 day ago· $200 Million For Advanced Energy Storage Torus Energy is among the flywheel innovators ready to push their technology into the market here and now.

Get Price

Flywheel energy storage cost calculation scheme

FES system. And main factors like total energy losses, safety, cost control are discussed. Finally, application area of FES technology is presented including energy storage and attitude control

Get Price

Flywheel Energy Storage Study

The core of this particular FES System technology involves the development of a lower-cost steel flywheel, which will reduce the first cost of the energy storage device, while delivering the

Get Price

Flywheel energy storage systems: A critical review on

In this article, an overview of the FESS has been discussed concerning its background theory, structure with its associated components,

Get Price

The Status and Future of Flywheel Energy Storage

Flywheels, one of the earliest forms of energy storage, could play a significant role in the transformation of the electrical power system into one that is fully sustainable yet low

Get Price

Flywheel Energy Storage System: What Is It and How

Wind and solar energy have brought us powerful and almost eternal energy. How to flexibly store, control and use this energy has become the key. This article

Get Price

Overview of Flywheel Systems for Renewable Energy

Energy can be stored through various forms, such as ultra-capacitors, electrochemical batteries, kinetic flywheels, hydro-electric power or compressed air. Their comparison in terms of specific

Get Price

The Status and Future of Flywheel Energy Storage

Outline Flywheels, one of the earliest forms of energy storage, could play a significant role in the transformation of the electri-cal power system into one that is fully sustainable yet low cost.

Get Price

Flywheel Energy Storage Costs: Breaking Down the Economics

Notice how per-unit costs decrease with scale - the 10 MW Jinan project achieved 18% lower per-MW pricing than smaller installations. This scaling effect mirrors what we''ve seen in solar PV

Get Price

Flywheel Energy Storage for Residential Use: A Cost

Explore a cost-effective flywheel energy storage system (FESS) for homes. Design, materials, integration, and safety considerations are discussed.

Get Price

Cost-Benefit Analysis of Flywheel Energy Storage in context of flywheel

Conducting detailed cost-benefit analyses for specific FES applications, such as frequency regulation or renewable energy integration. Investigating the impact of FES on grid

Get Price

Flywheel Storage Systems | SpringerLink

The components of a flywheel energy storage systems are shown schematically in Fig. 5.4. The main component is a rotating mass that is held via magnetic bearings and

Get Price

6 FAQs about [Cost Control of Flywheel Energy Storage Construction]

Are flywheel energy storage systems economically feasible?

Equipment cost distribution for the flywheel energy storage systems. FESSs are used for short-duration power applications. Therefore, power capital cost ($/kW) could be a useful parameter to compare the economic feasibility of energy storage systems for similar power applications.

Does a flywheel storage system need a bottom-up research?

However, almost no bottom-up research has been done, i.e., research that considers the technical parameters to size the components of a flywheel storage system, estimate cost parameters based on the design, and provide a probable distribution of the total investment cost and levelized cost of storage.

How can flywheels be more competitive to batteries?

The use of new materials and compact designs will increase the specific energy and energy density to make flywheels more competitive to batteries. Other opportunities are new applications in energy harvest, hybrid energy systems, and flywheel’s secondary functionality apart from energy storage.

What is the power rating of a flywheel energy storage system?

Utility-scale energy storage systems for stationary applications typically have power ratings of 1 MW or more . The largest flywheel energy storage is in New York, USA by Beacon Power with a power rating of 20 MW and 15 min discharge duration .

How much does a steel rotor flywheel cost?

The steel rotor flywheel has a lower capital cost and levelized cost of storage. The costs of composite and steel rotor flywheels are $190 and $146/MWh, respectively. Flywheel energy storage systems are increasingly being considered as a promising alternative to electro-chemical batteries for short-duration utility applications.

Do flywheels perform well in large-scale applications?

There is a scarcity of research that evaluates the techno-economic performance of flywheels for large-scale applications. Evaluating the capital cost, levelized cost of storage, and scale factor is crucial to make an informed decision in future development and deployment of the technology.

More related information

-

How much does flywheel energy storage wind power cost

How much does flywheel energy storage wind power cost

-

Flywheel energy storage equipment construction

Flywheel energy storage equipment construction

-

Progress of flywheel energy storage construction in Vanuatu

Progress of flywheel energy storage construction in Vanuatu

-

Afghanistan Energy Storage Project Cost Control

Afghanistan Energy Storage Project Cost Control

-

Cost Estimation of Flywheel Energy Storage

Cost Estimation of Flywheel Energy Storage

-

Energy storage construction cost per kilowatt-hour

Energy storage construction cost per kilowatt-hour

-

Construction cost of energy storage system for communication base stations

Construction cost of energy storage system for communication base stations

-

Bangladesh flywheel energy storage construction costs

Bangladesh flywheel energy storage construction costs

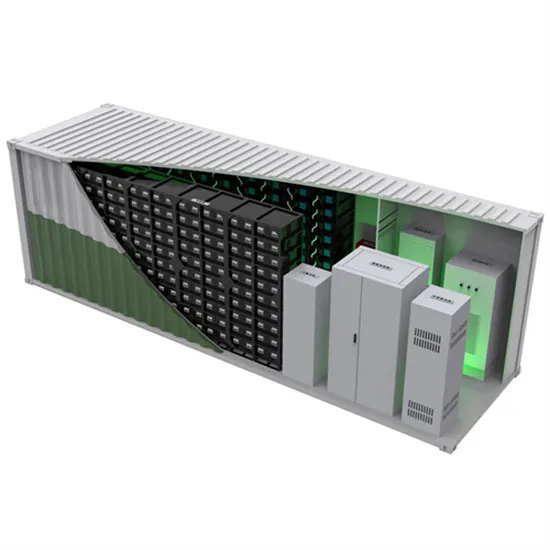

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.