Pyrolysis-based separation mechanism for waste

Heating treatment is the mainstream method to separate the modules in the waste photovoltaic (PV) module recycling process, which has

Get Price

A Review of End-of-Life Silicon Solar Photovoltaic Modules

Silicon photovoltaics dominate the solar PV market and consti-tute over 90% of the global market.[5,14] Despite developments made in alternative photovoltaic technologies, it is

Get Price

Photovoltaic panel wafer separation

This paper offers a comprehensive overview of the separation processes for silicon PV modules and summarizes the attempts to design easily recyclable modules for

Get Price

Photovoltaic panel silicon wafer glass separation method

The method adopts a combined method of heat treatment technology and chemical method to realize waste crystalline silicon solar panel frame, glass recovery and silicon wafer separation,

Get Price

Separation of photovoltaic panel glass and silicon wafer

How to reclaim silicon (Si) wafer from end-of-life photovoltaic module? A sustainable method for reclaiming silicon (Si) wafer from an end-of-life photovoltaic module is examined in this paper.

Get Price

Investigation of Ferrosilicon Produced with Si Recovered from

The recycled silicon was obtained by crushing and sorting to recover silicon from the end-of-life PV panels. The PV panels were crushed using an industrial crushing tool and

Get Price

Enhanced separation of different layers in photovoltaic panel by

With the rapid increase of photovoltaic (PV) system production and installation, the recycling of end-of-life PV modules has become a grave issue. In this paper, a new method of

Get Price

Eco-friendly method for reclaimed silicon wafer from

A sustainable method for reclaiming silicon (Si) wafer from an end-of-life photovoltaic module is examined in this paper. A thermal process was employed to remove ethylene vinyl acetate

Get Price

Thermal delamination of end-of-life crystalline silicon photovoltaic

Thermal delamination – meaning the removal of polymers from the module structure by a thermal process – as a first step in the recycling of crystalline silicon (c-Si)

Get Price

Review of silicon recovery in the photovoltaic industry

The photovoltaic industry is developing rapidly to support the net-zero energy transition. Among various photovoltaic technologies, silicon-based technology is the most

Get Price

Silicon Extraction Methods from Recycled Solar Cells

Discover techniques for extracting silicon from recycled solar cells, promoting sustainability and advancing renewable energy solutions.

Get Price

Pyrolysis-based separation mechanism for waste crystalline

Heating treatment is the mainstream method to separate the modules in the waste photovoltaic (PV) module recycling process, which has not been studied thoroughly. In the present study, a

Get Price

An eco-friendly method for reclaimed silicon wafers

A sustainable method for reclaiming silicon (Si) wafers from an end-of-life photovoltaic module is examined in this paper. A thermal process was

Get Price

Environmentally Sustainable Recycling of Photovoltaic Panels

1 day ago· This article presents an innovative and highly sustainable method for recycling photovoltaic (PV) panels laminated with very soft polydimethylsiloxane (PDMS) gels. This

Get Price

Experimental Methodology for the Separation

As the use of photovoltaic installations becomes extensive, it is necessary to look for recycling processes that mitigate the environmental impact of damaged or

Get Price

Research and development priorities for silicon photovoltaic

The increasing deployment of photovoltaic modules poses the challenge of waste management. Heath et al. review the status of end-of of-life management of silicon solar

Get Price

Thermal–Mechanical Delamination for Recovery of

This paper presents a sustainable recycling process for the separation and recovery of tempered glass from end-of-life photovoltaic (PV)

Get Price

Assessing the Feasibility of Integrating a Thermal

The recovered silicon wafers and tempered glass sheets were utilized to fabricate new PV panels using lamination technology. The applied

Get Price

A method to recycle silicon wafer from end-of-life photovoltaic

We investigated a new method for reclaiming Si wafers from EoL PV modules by applying etching paste and for the manufacture of Pb-free solar panels. Ag and Al metal

Get Price

Unlocking silver from end-of-life photovoltaic panels: A concise

The long-term viability of solar cells significantly relies on the sustainable availability of these critical raw materials. Recycling end-of-life solar panels is a beneficial practice that

Get Price

Introduction to solar photovoltaic panel separator

Its main function is to separate the photovoltaic panels from the silicon wafers. The equipment achieves an efficient and environmentally friendly separation process by precisely controlling

Get Price

Experimental Methodology for the Separation Materials in the

There is no single path for recycling silicon panels, some works focus on recovering the reusable silicon wafers, others recover the silicon and metals contained in the

Get Price

Solar Wafers: The Building Blocks of Photovoltaic Technology

Key Takeaways Solar panels mainly use monocrystalline or polycrystalline silicon for today''s photovoltaic technology. Monocrystalline silicon wafers show excellent

Get Price

Experimental Methodology for the Separation Materials in the

As the use of photovoltaic installations becomes extensive, it is necessary to look for recycling processes that mitigate the environmental impact of damaged or end-of-life photovoltaic panels.

Get Price

6 FAQs about [Photovoltaic panel silicon wafer solar panel separation]

How to reclaim silicon (Si) wafer from end-of-life photovoltaic module?

A sustainable method for reclaiming silicon (Si) wafer from an end-of-life photovoltaic module is examined in this paper. A thermal process was employed to remove ethylene vinyl acetate and the back-sheet. We found that a ramp-up rate of 15 °C/min and an annealing temperature of 480 °C enabled recovery of the undamaged wafer from the module.

How to recover silicon (Si) wafer from solar panels?

This paper details an innovative recycling process to recover silicon (Si) wafer from solar panels. Using these recycled wafers, we fabricated Pb-free solar panels. The first step to recover Si wafer is to dissolve silver (Ag) and aluminium (Al) via nitric acid (HNO3) and potassium hydroxide (KOH), respectively.

Can silicon wafers be recovered from end-of-life solar panels?

A method for recovering silicon wafers from end-of-life solar panels was investigated. The properties of recycled wafers are almost identical to those of commercial virgin wafers. The conversion efficiency of the remanufactured solar cells fell in the range of 15.0–16.0%. Solar modules, which contain these cells, show good stability.

Why is it important to separate different layers of PV panels?

It is very important to realize the rapid and efficient separation between the different layers of the PV panels. After the separation of different layers, valuable materials such as silver wires, silver paste electrodes, and Cu/Sn ribbons be exposed which is necessary for the extraction the valuable materials.

How does a silicon wafer affect the microwave absorbing rate?

The anti-reflection layer on the surface of the silicon wafer played a key role on the microwave absorbing. The separation rate reaches 100% in 2 h. With the rapid increase of photovoltaic (PV) system production and installation, the recycling of end-of-life PV modules has become a grave issue.

How to determine the degree of separation of PV panels?

In order to evaluate the degree of separation of PV panels, the separation rate of PV panels was introduced in this paper and it was determined by Eq. (1): (1) Separation rate ( %) = ( 1 − M b M a) × 100 where Mb is the mass of unseparated PV panels and Ma is the total mass of the PV panels placed in the reactor.

More related information

-

Photovoltaic silicon solar panel manufacturer

Photovoltaic silicon solar panel manufacturer

-

Columbia Transparent Series Photovoltaic Solar Panel Crystalline Silicon

Columbia Transparent Series Photovoltaic Solar Panel Crystalline Silicon

-

Solar photovoltaic panel 340w polycrystalline silicon

Solar photovoltaic panel 340w polycrystalline silicon

-

Vatican solar photovoltaic panel manufacturer

Vatican solar photovoltaic panel manufacturer

-

Monocrystalline silicon and polycrystalline silicon photovoltaic panel installation

Monocrystalline silicon and polycrystalline silicon photovoltaic panel installation

-

Solar photovoltaic panel trends

Solar photovoltaic panel trends

-

Huawei power generation solar panel photovoltaic curtain wall advantages

Huawei power generation solar panel photovoltaic curtain wall advantages

-

Tanzania photovoltaic solar panel batteries

Tanzania photovoltaic solar panel batteries

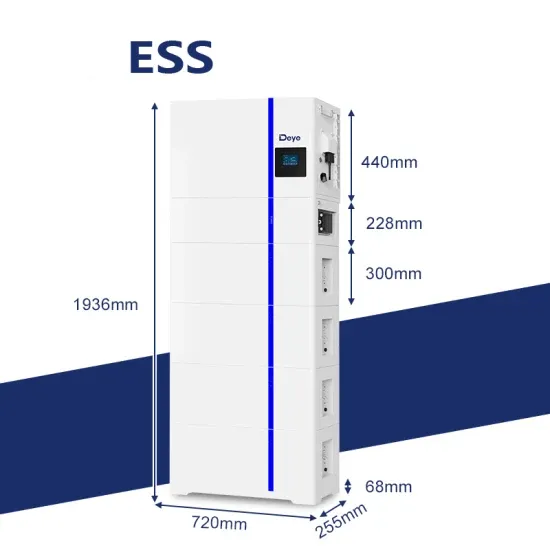

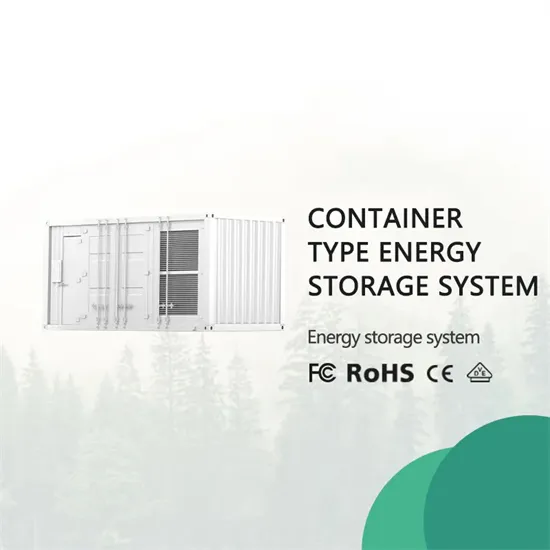

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.