Svolt Energy''s Thailand plant sees 1st battery pack roll off line

Svolt Energy''s first battery pack produced in Thailand is expected to be available in volume in the first quarter of 2024, and will first be fitted to the Thai version of the Good Cat

Get Price

Thailand Approves Sunwoda to Invest More Than

Sunwoda''s battery cell manufacturing facilities in Thailand will be its first EV-related battery cell factory in the ASEAN region.

Get Price

Amita Technology''s Gigafactory: Thailand''s Homegrown EV Battery

3 days ago· Amita Technology, a local Thai company and the first lithium-ion battery gigafactory in ASEAN, is committed to completing Thailand''s electric vehicle (EV) ecosystem by

Get Price

SVOLT Thailand factory hits 10,000th EV battery pack milestone

Shanghai (Gasgoo)- On June 30, 2025, Chinese battery manufacturer SVOLT, in partnership with Thailand''s Banpu, celebrated a significant milestone at their joint venture

Get Price

Top Lithium Ion Battery Manufacturers in Thailand

As the global shift toward clean energy accelerates, Thailand is emerging as a key player in the lithium-ion battery market, driven by its strategic position in

Get Price

Gotion''s Thailand JV sees 1st battery pack roll off line

The battery pack, based on lithium iron phosphate chemistry, has a capacity of 38 kWh, which can allow an electric vehicle (EV) to achieve a

Get Price

Best lithium ion battery suppliers | lithium ion battery

We only adoption the A grade battery cells. Existing customized solutions and products for lithium batteries are widely used in industrial energy storage,

Get Price

SVOLT Thailand and Banpu NEXT Celebrates Its First Battery

The successful launch of the first battery pack marks a new stage of cooperation between the two parties. In the future, they will continue to expand Thailand and Southeast

Get Price

BSLBATT Industrial Lithium Batteries

At BSLBATT, we put the quality and safety of our products first. Partnering with CATL, REPT, EVE and other top battery manufacturers, we focus only on premium lithium iron phosphate

Get Price

First Battery Pack From Svolt''s Thai Plant Rolls Off

LCPT battery packs are cheaper and have higher production efficiency and energy density, so that they can meet the needs of A-class

Get Price

Battery Maker Svolt Energy Inaugurates Production Line in Thailand

Battery maker Svolt Energy just inaugurated its first battery pack production line at its Thailand plant. The pack is Svolt Energy''s LCTP battery pack with a capacity of 60 kWh, providing a

Get Price

Panasonic Energy Co., Ltd.

Panasonic Energy Begins Mass Production at New Automotive Lithium-ion Battery Factory in Kansas, Aiming for Annual Capacity of 32 GWh to Accelerate U.S. Local Production

Get Price

Amita''s Lithium Ion Battery Gigafactory in Thailand

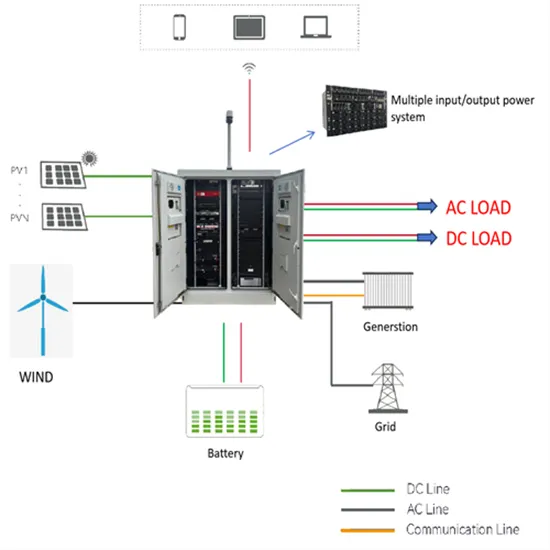

Battery Energy Storage System (ESS) the Critical Link of Power Network Higher Penetration of VRE Higher Electricity Demand of EV Thailand New era of Advance Technology for Battery

Get Price

LISHEN | LISEHN Battery | Lithium Battery | Li-ion

LISHEN is a leading lithium battery manufacturer and supplier for EV power and energy storage solutions. LISHEN specializes in the electric

Get Price

Sino-Thai EV battery plant starts operations

Thailand''s first domestic electric vehicle battery pack production plant went into operation on Thursday. The plant, run jointly by Chinese battery cell manufacturer Gotion High-tech and

Get Price

Top Lithium Ion Battery Manufacturers in Thailand

As the global shift toward clean energy accelerates, Thailand is emerging as a key player in the lithium-ion battery market, driven by its strategic position in Southeast Asia''s electric vehicle

Get Price

Amita Technology''s Gigafactory: Thailand''s

3 days ago· Amita Technology, a local Thai company and the first lithium-ion battery gigafactory in ASEAN, is committed to completing Thailand''s electric

Get Price

Sino-Thai EV battery plant starts operations

Thailand''s first domestic electric vehicle battery pack production plant went into operation on Thursday. The plant, run jointly by Chinese battery cell

Get Price

ROYPOW® Official

Dedicated to the lithium-ion battery systems as one-stop solutions to achieve enegy innovation and build world-renowned renewable energy brand. At present, ROYPOW products cover all

Get Price

SVOLT Thailand Joint Venture Hits 10000 Battery Pack Milestone

SVOLT celebrates 10,000 EV battery packs milestone at Thailand joint venture factory, showcasing advanced battery tech and sustainable energy expansion in Southeast Asia.

Get Price

Battery Maker Svolt Energy Inaugurates Production Line in Thailand

Svolt Energy''s first battery pack produced in Thailand is expected to be available in volume in the first quarter of 2024, and will first be fitted to the Thai version of the Good Cat model of Great

Get Price

Svolt Energy''s Thailand plant sees 1st battery pack

Svolt Energy''s first battery pack produced in Thailand is expected to be available in volume in the first quarter of 2024, and will first be fitted to

Get Price

First Battery Pack From Svolt''s Thai Plant Rolls Off Production Line

LCPT battery packs are cheaper and have higher production efficiency and energy density, so that they can meet the needs of A-class vehicles in the Thai market. They will be

Get Price

SVOLT Thailand and Banpu NEXT Celebrates Its First Battery Pack

After the series production of the EV battery pack in the next February, we will continue to focus on our integrated energy storage production line and develop our light power

Get Price

GPSC To Build Battery Plant In Thailand For 24M

GPSC To Build Battery Plant In Thailand For 24M Semi-Solid Tech High-energy density lithium-ion batteries with 24M SemiSolid technology to be produced in

Get Price

SVOLT shows off first Thai-made lithium battery pack

SVOLT Energy Technology has produced its first EV battery pack in Thailand, which will be supplied for the locally-assembled GWM ORA Good Cat scheduled for next year.

Get Price

Lithium-Ion Batteries | Lithium-Ion Battery Supplier & Battery Pack

Voltaplex Energy offers industry-leading energy storage solutions by supplying wholesale lithium-ion batteries and battery pack manufacturing. As one of the most trusted lithium-ion battery

Get Price

6 FAQs about [Thailand new energy lithium battery pack]

Why is Thailand a key player in the lithium-ion battery market?

As the global shift toward clean energy accelerates, Thailand is emerging as a key player in the lithium-ion battery market, driven by its strategic position in Southeast Asia’s electric vehicle (EV) and renewable energy boom.

Who is Thai storage battery?

Overview: Thai Storage Battery is one of the oldest battery manufacturers in Thailand, known for its strong presence in the automotive and industrial sectors. TSB is transitioning into lithium-ion but remains a key player in traditional batteries. Established Time: 2023

Are battery manufacturers eligible for tax incentives in Thailand?

Battery manufacturers will receive significant tax incentives in Thailand. They are eligible for a 90% reduction in import duty for materials used in production and a full import duty exemption for research materials. Additionally, those with investment privileges will receive subsidies for investment, research, and personnel training.

How many gigawatts a year can a lithium ion battery produce?

Focused on the import, assembly and distribution of battery modules and battery packs for energy storage systems and EVs, the plant will deliver high-quality lithium ion batteries with an initial production capacity of 2 gigawatt-hours per year.

Are EVs a new start in Thailand?

"This is a new start in Thailand with great vitality, as a revolution is now coming strongly with the energy storage of solar and wind power as a key role," he said, adding that the EV market in Thailand has great potential, as EVs currently constitute only a tiny portion of the country's total vehicle number.

Why should you invest in EVs in Thailand?

Additionally, those with investment privileges will receive subsidies for investment, research, and personnel training. Amita Technology, a local Thai company and the first lithium-ion battery gigafactory in ASEAN, is committed to completing Thailand's electric vehicle (EV) ecosystem by developing battery manufacturing from upstream to downstream.

More related information

-

Cook Islands new energy storage lithium battery pack

Cook Islands new energy storage lithium battery pack

-

New energy new lithium battery pack

New energy new lithium battery pack

-

Which lithium battery pack is best in Thailand

Which lithium battery pack is best in Thailand

-

Australian home energy storage lithium battery pack

Australian home energy storage lithium battery pack

-

New lithium iron phosphate battery pack factory in St Lucia

New lithium iron phosphate battery pack factory in St Lucia

-

New Zealand energy storage low temperature lithium battery

New Zealand energy storage low temperature lithium battery

-

Benin New Energy Lithium Battery BMS Standard

Benin New Energy Lithium Battery BMS Standard

-

Lithium battery pack for energy storage

Lithium battery pack for energy storage

Commercial & Industrial Solar Storage Market Growth

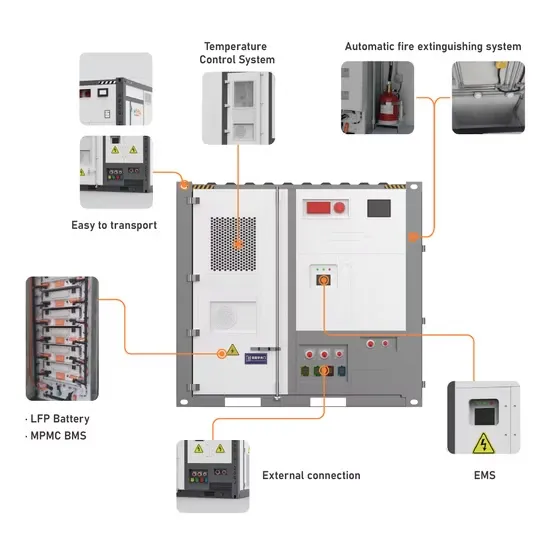

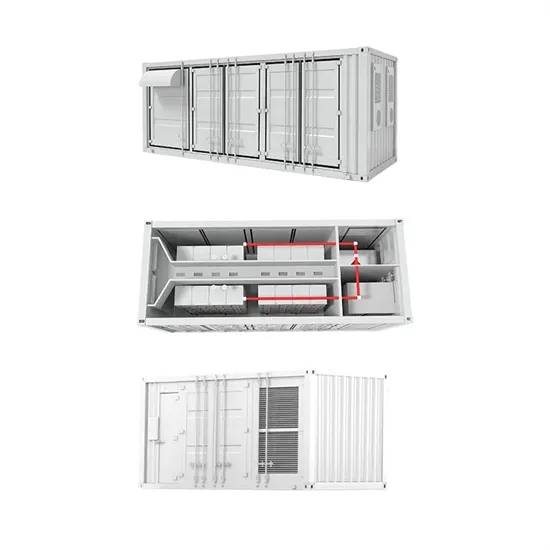

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.