The Science Behind Lithium Battery Capacity Loss

Understanding what causes capacity loss of lithium battery packs is essential for optimizing performance and extending service life in business-critical applications. You

Get Price

Cell Inconsistency in Lithium Batteries: Root Causes and

Q1: Can inconsistent cells be "repaired" in existing packs? No – but active balancing can mitigate 80% of capacity loss. Prevention starts at cell selection. Q2: Why are LiFePO₄

Get Price

Understanding Lithium Ion Battery Capacity

However, over time, these batteries experience a decline in performance, often referred to as capacity degradation. This article explores

Get Price

Capacity and impedance characteristics of the lithium-ion battery

The rapid development of hybrid electric vehicles and electric vehicles increases the popularity of lithium-ion batteries [1]. As a key component of these vehicles, the lithium-ion battery largely

Get Price

Capacity evaluation and degradation analysis of lithium-ion

Accurately calculating the capacity of battery packs is of great significance to battery fault diagnosis, health evaluation, residual value assessment, and predictive

Get Price

Degradation in parallel-connected lithium-ion battery packs under

Practical lithium-ion battery systems require parallelisation of tens to hundreds of cells, however understanding of how pack-level thermal gradients influence lifetime

Get Price

How Are Lithium Batteries Made?

Learn how lithium batteries are made with LiFePO4 chemistry, 72-hour aging tests, and 99.9% defect-free production. Design your pack today.

Get Price

What Are the Primary Causes of Capacity Degradation in Lithium

Deep discharging your lithium-ion battery can lead to diminished capacity over time. Why This Matters: Lithium-ion batteries prefer to be kept within a certain charge range. Regularly

Get Price

Bad Battery Cell Symptoms, Causes & Fixes | Lithium-Ion Battery

In this guide, you''ll learn how to spot the symptoms of a bad battery cell, understand what causes battery failure, and explore the right ways to test, dispose of, and maintain your batteries to

Get Price

Introduction: What Is a Lithium-Ion Battery Pack?

Lithium-ion battery packs are essential power sources used in medical equipment, drones, robots, and countless other devices. These packs are made of multiple Li-ion cells

Get Price

How to Choose the Right Ah for 48V Li-ion Battery Pack?

Part 1. Key components Before we talk about capacity, let''s quickly understand what makes up a 48V Li-ion battery pack. A standard battery pack includes: Lithium-ion Cells:

Get Price

Understanding Lithium Ion Battery Capacity Degradation: Causes

However, over time, these batteries experience a decline in performance, often referred to as capacity degradation. This article explores the causes of lithium-ion battery

Get Price

How to Recondition Lithium-Ion Batteries

Can You Recondition Lithium-Ion Batteries? Yes, you can recondition lithium-ion batteries once they stop performing at full capacity.

Get Price

Consistency evaluation and cluster analysis for lithium-ion battery

Consistency is an essential factor affecting the operation of lithium-ion battery packs. Pack consistency evaluation is of considerable significance to the usage of batteries.

Get Price

Capacity evaluation and degradation analysis of lithium-ion battery

Accurately calculating the capacity of battery packs is of great significance to battery fault diagnosis, health evaluation, residual value assessment, and predictive

Get Price

How to Find Bad Cells in a Battery Pack? A Step-by-Step Guide

Several factors can cause a cell to go bad: Age: Over time, battery cells lose their capacity to hold a charge. Overcharging or Deep Discharge: Charging a cell past its limit or

Get Price

Causes Of Lithium Battery Pack Failure

In summary, the top causes of lithium-ion battery failure include charger issues, cell short circuits, punctures and leakage, battery pack swelling, and overheating. Proper charger usage, quality

Get Price

What Causes a Battery to Lose Capacity?

Simply put, battery capacity indicates how much charge a battery can store at a given time, determining how long it can supply power. But over

Get Price

BU-802: What Causes Capacity Loss?

Lithium- and nickel-based batteries deliver between 300 and 500 full discharge/charge cycles before the capacity drops below 80 percent.

Get Price

Lithium battery pack bulge causes and treatment methods

Lithium battery science popularization, lithium battery pack bulge causes and treatment methods The development of lithium batteries was earlier, but due to fierce

Get Price

Common Issues With Lithium-Ion Batteries and How to Fix Them

Common problems with lithium-ion batteries include rapid discharge, failure to charge, unexpected shutdowns, and battery drain in idle devices. These issues can relate to energy

Get Price

Evaluation method for consistency of lithium-ion battery packs in

Lithium-ion batteries, used in EVs, have the advantages of cleanliness, high energy density, and low self-discharge rate [2]. The battery pack for EVs usually contains hundreds to

Get Price

Lithium-Ion Battery Packs | Electronic Components

Lithium-Ion Battery Packs A battery pack is a set of any number of battery cells connected and bound together to form a single unit with a specific

Get Price

Common Issues With Lithium-Ion Batteries and How

Common problems with lithium-ion batteries include rapid discharge, failure to charge, unexpected shutdowns, and battery drain in idle devices. These

Get Price

Advantages and disadvantages of lithium-ion batteries

Designing a battery system that encompasses specific volume requirements offers a prolonged life cycle and exhibits rapid charge and discharge characteristics necessitates

Get Price

Why Battery Capacity Decreases

The Chemistry Behind Battery Capacity Loss. Battery degradation isn''t just about usage – it''s fundamentally a chemical process. Lithium-ion batteries, which power most moder

Get Price

What Causes a Battery to Lose Capacity?

Simply put, battery capacity indicates how much charge a battery can store at a given time, determining how long it can supply power. But over time, you may notice your

Get Price

A review on electrical and mechanical performance parameters in lithium

It leaves aside a holistic and comprehensive study to evaluate performance in lithium-ion battery packs. This review paper presents more than ten performance parameters

Get Price

6 FAQs about [Poor capacity of lithium battery pack]

What are common problems with lithium-ion batteries?

These common issues with lithium batteries can disrupt our daily routines, compromise our safety, and decrease the lifespan of our beloved gadgets. Identifying common problems with lithium-ion batteries is key to preventing mishaps and ensuring your devices function efficiently. One frequent lithium-ion battery problem is rapid discharge.

Why does a lithium ion battery lose capacity?

Each time a lithium-ion battery goes through a discharge and charge cycle, it experiences physical and chemical changes that contribute to capacity loss. This can include the formation of solid electrolyte interphase (SEI) layers, which can hinder ion movement.

How does a lithium ion battery affect its capacity?

Electrolyte Decomposition: The electrolyte, a key player in a battery, is prone to decomposition over time, which affects battery capacity. Solid Electrolyte Interface (SEI) Layer Formation: Lithium-ion batteries often form an SEI layer over time, which reduces ion movement and thus, battery capacity.

What causes a bad battery pack?

It might not be your device that's the problem but the battery pack itself. Specifically, a bad cell or two inside the pack could be causing the issue. Don’t worry—finding and diagnosing bad cells in a battery pack is simpler than it sounds.

How does a lithium ion battery degrade?

Batteries degrade with use and age, leading to a phenomenon known as cycling degradation. Each time a lithium-ion battery goes through a discharge and charge cycle, it experiences physical and chemical changes that contribute to capacity loss.

Why do lithium-ion batteries overheat?

The answer lies in the design and chemistry of these batteries. When used excessively or charged improperly, lithium-ion batteries generate excessive heat. This heat can lead to thermal runaway, a rapid, uncontrolled chemical reaction that results in overheating. So, how can we prevent this from happening?

More related information

-

Capacity of lithium battery pack

Capacity of lithium battery pack

-

Niue large capacity lithium battery pack

Niue large capacity lithium battery pack

-

High capacity lithium battery pack customization

High capacity lithium battery pack customization

-

Large capacity lithium battery pack wholesale

Large capacity lithium battery pack wholesale

-

Lithium battery pack voltage and capacity

Lithium battery pack voltage and capacity

-

Large capacity 30a lithium battery pack

Large capacity 30a lithium battery pack

-

Ultra-large capacity 16 8v lithium battery pack

Ultra-large capacity 16 8v lithium battery pack

-

High capacity lithium battery pack supplier

High capacity lithium battery pack supplier

Commercial & Industrial Solar Storage Market Growth

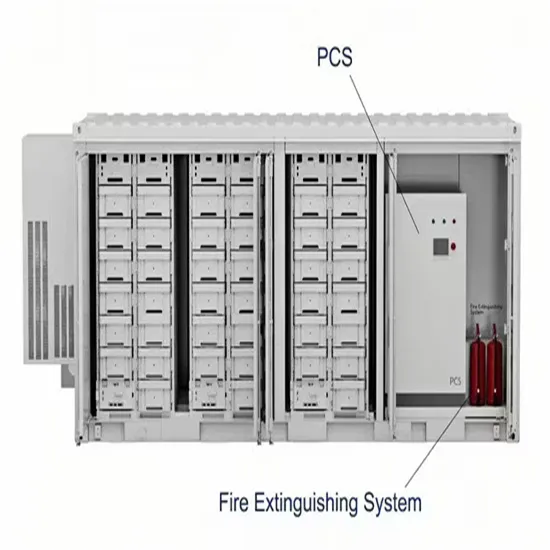

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.