Unraveling the Silver Learning Curve for Photovoltaics

The widely used p-type PERC cells consume 14.4-15.7 mg of silver per watt, while next-generation, high-efficiency n-type TOPCon and SHJ cells have higher silver

Get Price

Amount of silver needed in solar cells to be more than halved by

The authors also predict cell output will grow from 4.7 W now to 6 W by 2030, contributing to a 10.5 mg reduction in silver use per Watt, the report notes.

Get Price

How many grams of silver and silicon does a photovoltaic

Silver plays a vital role in producing solar power,with the average panel containing about 20 gramsof silver and utilizing between 3.2 to 8 grams per square meter. How is Silver

Get Price

How much silver is needed for the solar panel industry?

Current panel efficiency levels range between 15% and 20%, making silver a necessary factor for energy production expansion. Professionals expect

Get Price

How is silver used in solar energy

This fact makes potential silver substitutes like copper and nickel phosphide inferior to silver in solar panels. Without silver, solar panels could not be as efficient in turning sunlight into

Get Price

How Much Energy to Make a Solar Panel?

If a solar panel is 100 watts and gets 10 hours of direct sunlight each day, it produces 1000 watts (or 1 kilowatt-hour) of energy per day. That''s

Get Price

Is there a silver bullet for precious metal use in n-type

The two-pronged attack of growing solar capacity and the shift to n-type has made silver a pressure point for future solar manufacturing.

Get Price

Solar Panel Calculator: How Many Do You Need?

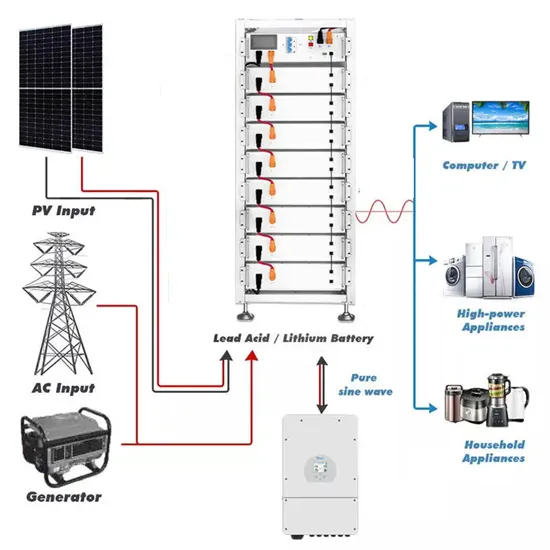

Determining the Electrical Load: What Devices? The point of a solar system is to power your things. Calculating your solar panel needs starts with figuring out how much total

Get Price

Silver Consumption in Solar PV

There are some competing sources for the amount of silver used per Watt of solar capacity. The sources I''ve found use milligrams per Watt (mg/W) to describe the amount of

Get Price

Copper and Silver: The Electrical Metals | SilverSeek

A 2020 Saxo Bank report stated that "potential substitute metals cannot match silver in terms of energy output per solar panel." Despite not

Get Price

How Many Solar Panels Do I Need To Power a House

An easy guide to finding out how many solar panels you need to install to fully offset your electricity usage.

Get Price

Solar Photovoltaic System Cost Benchmarks

The U.S. Department of Energy''s solar office and its national laboratory partners analyze cost data for U.S. solar photovoltaic systems to develop cost

Get Price

Silver Consumption in Solar PV

There are some competing sources for the amount of silver used per Watt of solar capacity. The sources I''ve found use milligrams per Watt

Get Price

Silver Demand Grows as Solar Leads Renewables

Using BloombergNEF''s estimate of 12 tonnes of silver demand per gigawatt of solar capacity, silver demand for solar panels could increase by almost 169% by 2030 to

Get Price

The world''s appetite for solar panels is squeezing silver supply

While PERC cells need about 10 milligrams of silver per watt, TOPCon cells require 13 milligrams and heterojunction 22 milligrams. At the same time, supply is starting to look

Get Price

Solar Installed System Cost Analysis

Solar Installed System Cost Analysis NREL analyzes the total costs associated with installing photovoltaic (PV) systems for residential rooftop, commercial rooftop, and utility-scale

Get Price

Demand for solar panels is squeezing silver supply

While PERC cells need about 10 milligrams of silver per watt, the latter require 13 milligrams and 22 milligrams, respectively. At the same time,

Get Price

The world''s appetite for solar panels is squeezing

While PERC cells need about 10 milligrams of silver per watt, TOPCon cells require 13 milligrams and heterojunction 22 milligrams. At the

Get Price

Solar Energy''s Demand: How Much Silver Is Needed for Panels?

As global solar PV demand skyrockets, discover how much silver is essential for solar panels and the forecast for silver''s role in the expanding PV market.

Get Price

How Much Silver is in a Solar Panel?

This Answer explores the silver content of solar panels, how they are made, and some of the implications of industrial silver use.

Get Price

How Much Silver is in a Typical Solar Panel? – Jeannie Blog

On average, a typical solar panel contains about 20 grams of silver. While this may not seem like a lot, when scaled across millions of solar panels produced each year, it

Get Price

How Much Silver is in a Typical Solar Panel? –

On average, a typical solar panel contains about 20 grams of silver. While this may not seem like a lot, when scaled across millions of solar

Get Price

Solar Panel Wattage Explained: How Many Watts Do

Confused about solar panel wattage? Learn how many watts you need, how solar output works, and how to calculate the right solar setup for

Get Price

Silver Demand Grows as Solar Leads Renewables

Using BloombergNEF''s estimate of 12 tonnes of silver demand per gigawatt of solar capacity, silver demand for solar panels could increase by

Get Price

How much silver is needed for the solar panel industry?

Current panel efficiency levels range between 15% and 20%, making silver a necessary factor for energy production expansion. Professionals expect technological advancements to increase

Get Price

How to Calculate Solar Panel KWp (KWh Vs. KWp + Meanings)

To calculate the KWp (kilowatt-peak) of a solar panel system, you need to determine the total solar panel area and the solar panel yield, expressed as a percentage.

Get Price

How Many kWh Does A Solar Panel Produce Per Day?

Solar Panel Size (Wattage). Most common solar panel sizes include 100-watt, 300-watt, and 400-watt solar panels, for example. The biggest the rated wattage of a solar panel, the more kWh

Get Price

How Much Silver Is Used in Solar Panels?

Because of silver''s high conductivity, it maximally converts sunlight into electricity. A recent market trend report conducted by London-based consultancy CRU explored the

Get Price

Unraveling the Silver Learning Curve for Photovoltaics

Silver consumption in solar cells is largely determined by the choice of solar cell technology. The widely used p-type PERC cells consume 14.4-15.7 mg of silver per watt, while

Get Price

Amount of silver needed in solar cells to be more than

The authors also predict cell output will grow from 4.7 W now to 6 W by 2030, contributing to a 10.5 mg reduction in silver use per Watt, the report

Get Price

6 FAQs about [How much silver is needed per watt of solar energy ]

How much silver does a solar panel use?

Silver is so crucial that it can equate up to 6 percent of the total cost of building each unit of the panel. The average panel of approximately 2 square meters can use up to 20 grams of silver. There’s a silver paste in the solar photovoltaic (PV) cells that collects the electrons generated when the sunlight hits the panel.

Why is silver important for solar energy production?

Current panel efficiency levels range between 15% and 20%, making silver a necessary factor for energy production expansion. Professionals expect technological advancements to increase the panels’ electricity outputs. Increasing efficiency while reducing silver usage requires PV research.

How much silver is used in solar cells?

The report's authors explain the amount of silver used in solar cell manufacturing has already decreased to a much larger extent, from 400 to 130 mg between 2007 and 2016. The authors also predict cell output will grow from 4.7 W now to 6 W by 2030, contributing to a 10.5 mg reduction in silver use per Watt, the report notes.

Is silver a good material for solar panels?

Silver is a significant PV panel material. Solar companies turn silver into a paste, loading it into each silicon wafer. When sunlight reaches a panel, silicon sets electrons free. Silver carries electricity through a current, reaching a building or battery for storage. Recently, manufacturers limited the quantity of silver in each panel.

How much silver is in the solar industry?

In the early 2000s, silver demand from the solar sector barely registered, making up less than a percent of silver demand. In 2019, the photovoltaic sector accounted for 10% of total silver demand, comprising 98.7 million ounces within total demand of 991.8 million ounces, according to Metals Focus data.

How much silver does PV use a year?

The CRU study predicts that the PV sector will consume about 81 million ounces of silver per year over the next decade. Much more silver was used in 2019 in making PV cells (100 million ounces). This anticipated drop implies that the market demand may have peaked in the previous year.

More related information

-

How many degrees is 1 watt of solar energy

How many degrees is 1 watt of solar energy

-

How many kilowatt-hours of electricity does one watt of solar energy generate

How many kilowatt-hours of electricity does one watt of solar energy generate

-

How many watts of photovoltaic solar energy are needed for home use

How many watts of photovoltaic solar energy are needed for home use

-

How many panels are needed for 5 kilowatts of solar energy

How many panels are needed for 5 kilowatts of solar energy

-

How many watts of solar energy are needed for 40 square meters

How many watts of solar energy are needed for 40 square meters

-

How many watts of solar energy are needed for 300 square meters

How many watts of solar energy are needed for 300 square meters

-

How many kilowatts of solar energy are needed for a villa

How many kilowatts of solar energy are needed for a villa

-

How many watts of solar energy does your home use

How many watts of solar energy does your home use

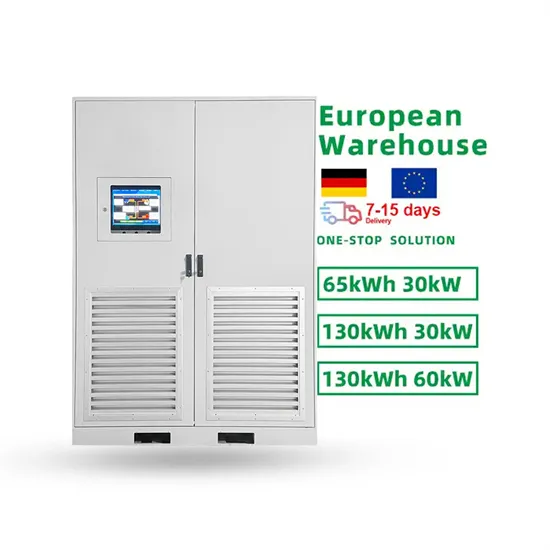

Commercial & Industrial Solar Storage Market Growth

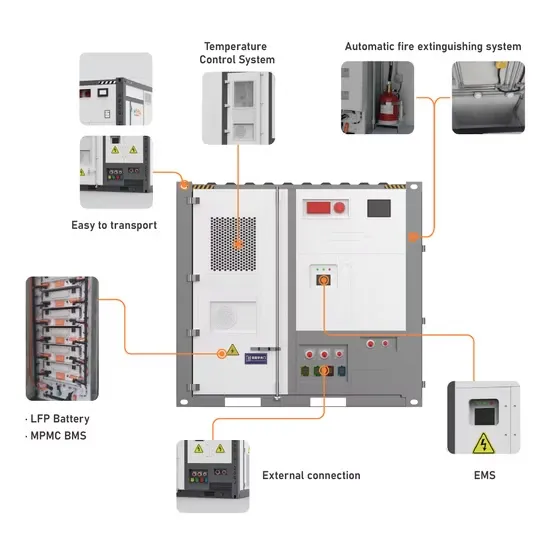

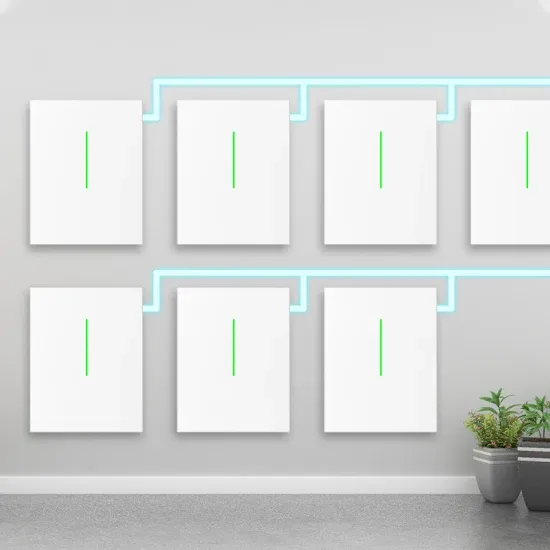

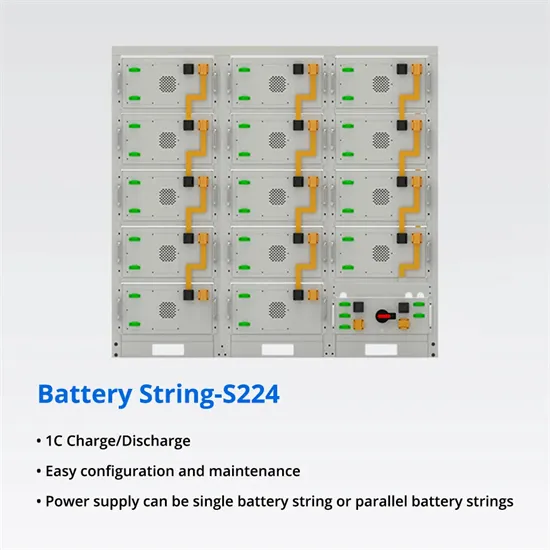

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.