(PDF) Six-phase Three-level Neutral Point Clamped Inverter for

In this paper, a six-phase three-level neutral point clamped (NPC) inverter is proposed to achieve active capacitor voltage balancing as well as common-mode voltage

Get Price

Analysis and Control of Neutral-Point Voltage for

The modulation strategy LMZVM (large, middle, and zero vector modulation) can be widely adopted in the three-level 7 photovoltaic (PV) inverter, because it reduces the

Get Price

Capacitor sizing of three‐level neutral point clamped voltage

A three-level neutral point clamped (3L-NPC) voltage source inverter (VSI) topology can be advantageous in electric vehicles with a high DC-link voltage and a high switching

Get Price

Neutral Point Shift | PDF | Electrical Impedance

The document discusses how medium voltage variable frequency drives (VFDs) can cause problems with motor neutral voltages due to neutral point shift. It

Get Price

Common Mode Voltage Reduction In Three Phase Neutral

The induction motor drive system consists of Neutral Point Clamped inverter to convert DC voltage to AC voltage and provide input to the induction motor. The NPC inverter, also termed

Get Price

Neutral Point Voltage of Electric Motor for Multilevel Drive in

Overall, this study contributes to the advancement of neutral point voltage inverters in multilevel electric motor drives, offering valuable insights and practical solutions to optimize the

Get Price

Three-level inverter-fed model predictive torque control of

Vol:.(1234567890) structures applied to medium-voltage motor drives is the three-level neutral point clamped inverter (3L-NPCI). Compared with typical two-level voltage source inverters, 3L

Get Price

Neutral-point voltage control of the three-level inverter in

A self-optimization mechanism of the three-phase switching sequence is proposed to achieve fully control of the neutral-point voltage with lowest switching times.

Get Price

Neutral Point Clamp Inverter and Dead Time

Diode D5 current and VaN voltage of inverter 2 are displayed on Scope2. When D5 fails open, its clamping effect to neutral is disabled and VaN voltage

Get Price

COMPARISON OF TWO-LEVEL AND THREE-LEVEL

techniques. The project also deals with the control of the Permanent Magnet Synchronous Motor drive using Field-Oriented Control Technique. From the detailed comparison, three-level

Get Price

Neutral-point voltage control method of multi-phase three-level neutral

In this paper, the neutral-point voltage control of space vector pulse width modulation (SVPWM) is studied. First, according to the principle of minimum common mode

Get Price

Capacitor sizing of three‐level neutral point clamped

A three-level neutral point clamped (3L-NPC) voltage source inverter (VSI) topology can be advantageous in electric vehicles with a high

Get Price

Mitigation of Common Mode Voltage in Induction Motor

The three- staggered inverter topology can be acknowledged by taking care of an open-end winding acceptance motor with two- staggered inverter from the two sides of the winding,The

Get Price

A Discontinuous PWM Method For Balancing The Neutral

In this paper, a new method based on a discontinuous PWM method is proposed for three-level inverters in order to reduce the NP voltage fluctuations without increasing the switching losses.

Get Price

A SVPWM based Neutral Point Voltage Control of 3 Level

Abstract Three-level Neutral Point Clamped (NPC) inverters are essential in high-power applications, including electric vehicles, renewable energy systems, and industrial drives, due

Get Price

Cascaded Active Neutral Point Clamped and Flying

AbstractThis paper proposes a novel multilevel architecture using active neutral point clamped inverter cascaded with a flying capacitor inverter to form a multilevel inverter topology with

Get Price

A closer look at multilevel traction inverters

EV Engineering News A closer look at multilevel traction inverters Posted March 20, 2025 by Jeffrey Jenkins & filed under Features, Newswire,

Get Price

Introduction to Three Level Inverter (TLI) Technology

Introduction to Three Level Inverter (TLI) Technology This Application Note reviews three level inverter topology, often referred to as Neutral Point Clamped (NPC) inverter. The three level

Get Price

Neutral point voltage of Electric motors for multilevel drives in

A Neutral Point Clamped MLI is used to convert DC power to AC power with multiple voltage levels. In an NPC MLI, the DC input power is converted into an AC output waveform with

Get Price

3-Level GaN Inverters for Highly Efficient Power Electronics in

An IGBT (Insulated-Gate Bipolar Transistor)-based 3L NPC (Neutral Point Clamping) inverter was developed as part of a comprehensive 4-in-1 system that integrates an

Get Price

DC-Link Voltage Stabilization and Capacitor Size Reduction in

This study examines the impact of midpoint voltage fluctuations on the performance of multilevel converters and proposes an advanced control strategy to reduce the

Get Price

Neutral-Point Voltage-Balancing Strategies of NPC-Inverter Fed

In this article, the mechanism of neutral-point potential oscillations of neutral-point-clamped (NPC) three-level inverter fed dual three-phase ac motors is described.

Get Price

A SVPWM based Neutral Point Voltage Control of 3 Level

This chapter examines the inverter''s neutral point voltage with diferent loads, motor control of the Permanent Magnet Synchronous Motor (PMSM), and various inverter profiles.

Get Price

Neutral-point voltage control of the three-level inverter in

Download Citation | On Sep 1, 2023, Xiang Wu and others published Neutral-point voltage control of the three-level inverter in permanent magnet synchronous motor based direct-drive belt

Get Price

Neutral-point voltage control method of multi-phase three-level

In this paper, the neutral-point voltage control of space vector pulse width modulation (SVPWM) is studied. First, according to the principle of minimum common mode

Get Price

6 FAQs about [Motor neutral point voltage and inverter]

What is neutral-point voltage control of space vector pulse width modulation (SVPWM)?

In this paper, the neutral-point voltage control of space vector pulse width modulation (SVPWM) is studied. First, according to the principle of minimum common mode voltage, the switching vector is selected, and the five-stage SVPWM method is adopted.

Can a multi-phase three-level inverter solve NPV balance problem?

However, the multi-phase three-level propulsion scheme needs to solve the neutral point voltage (NPV) balance problem of the multi-phase three-level H-bridge inverter.

What is the PF angle of a motor?

First, the motor is accelerated to a steady-state speed of 200 rpm under no-load operation, and the PF angle is 63°. Then two NPV control algorithms are added to compare the capacitor voltage balance time. The current amplitude of the two methods is about 12 A. Motor closed loop control block diagram

Can a 3l-npc H-bridge ship propulsion system control neutral-point voltage balance?

The research in this paper provides a viable method for the neutral-point voltage balance control of a 3L-NPC H-bridge ship propulsion system under low power-factor operation. The multi-level technology is an effective means to achieve a medium–high voltage and large-capacity power converter.

Why is DC NPV-regulation loop shared with a multi-phase motor?

Considering the influence of multi-phase load coupling, the same inner winding of the multi-phase motor is connected to the same DC bus, and the DC NPV-regulation loop is shared to improve the voltage regulation ability and to realize the decoupling control of the multi-phase winding of the motor.

What is NPV regulation in a 3l-npc H-bridge inverter driven 12-phase induction motor?

An experimental system of a twelve-phase 3L-NPC H-bridge inverter driven twelve-phase induction motor is built. The performance of NPV regulation before and after optimization is compared. First, the NPV-balance algorithm is not added to keep the motor speed up to the steady-state speed of 200 rpm.

More related information

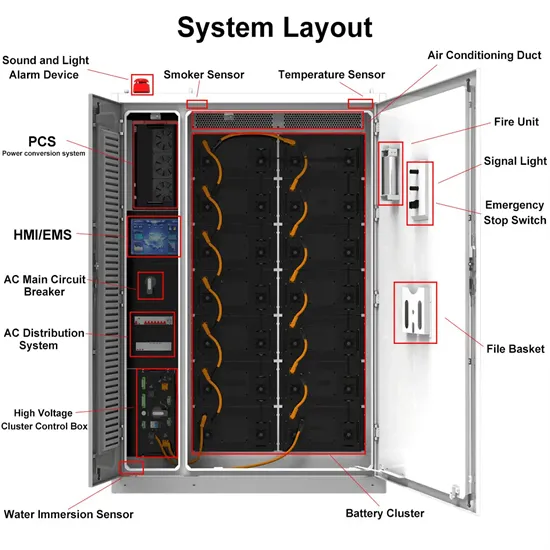

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.

VFD inverter neutral point voltage

VFD inverter neutral point voltage

Inverter tracks grid connection point voltage

Inverter tracks grid connection point voltage

Is it normal for the inverter to output 246V AC voltage

Is it normal for the inverter to output 246V AC voltage

Brazil high voltage inverter

Brazil high voltage inverter

Home storage system inverter output voltage

Home storage system inverter output voltage

Mexico high voltage inverter

Mexico high voltage inverter

American inverter voltage adjustable

American inverter voltage adjustable

AC low voltage inverter

AC low voltage inverter