Photovoltaic (PV) Cell: Working & Characteristics

PV cells can be made from many different types of materials and be using a range of fabrication techniques. As shown in Figure 1, the major categories of PV materials are crystalline silicon

Get Price

Photovoltaic Cell

Silicon photovoltaic cell, also referred to as a solar cell, is a device that transforms sunlight into electrical energy. It is made of semiconductor

Get Price

Solar Photovoltaic (PV) System Components

These modules consist of multiple strings of solar cells, wired in series (positive to negative), and are mounted in an aluminum frame. Each solar cell is capable of producing 0.5 volts.

Get Price

The Photovoltaic Cell Based on CIGS: Principles and

The AZO material is a transparent conductive oxide (OTC). 2.2. CIGS Cell Band Structure The band structure of a CIGS-based photovoltaic cell is shown in

Get Price

Cadmium Telluride

The U.S. Department of Energy (DOE) Solar Energy Technologies Office (SETO) supports innovative research focused on overcoming the current technological

Get Price

a typical c-Si material composition.

Download scientific diagram | a typical c-Si material composition. from publication: Integration & assessment of recycling into c-Si photovoltaic module''s life cycle

Get Price

Solar Photovoltaic Cell Basics

A thin-film solar cell is made by depositing one or more thin layers of PV material on a supporting material such as glass, plastic, or metal. There are two main

Get Price

Cells, Modules, Panels and Arrays

Photovoltaic cells are connected electrically in series and/or parallel circuits to produce higher voltages, currents and power levels. Photovoltaic modules

Get Price

Solar Panel Manufacturing Process: Step-by-Step Guide

Complete solar panel manufacturing process – from raw materials to a fully functional solar panel. Learn how solar panels are made in a solar manufacturing plant,

Get Price

EVA v/s POE: A Comparative Study of Solar Panel

In the solar energy sector, encapsulants play a vital role in protecting photovoltaic (PV) cells and enhancing the performance of solar

Get Price

Cadmium Telluride Solar Cells | Photovoltaic Research | NREL

Cadmium Telluride Solar Cells The United States is the leader in cadmium telluride (CdTe) photovoltaic (PV) manufacturing, and NREL has been at the forefront of research and

Get Price

Photovoltaic (PV) Cell: Structure & Working Principle

The article provides an overview of the structure and working principle of photovoltaic (PV) cell, focusing on the role of the PN junction in

Get Price

Solar Cell: Working Principle & Construction

Construction Details: Solar cells consist of a thin p-type semiconductor layer atop a thicker n-type layer, with electrodes that allow light

Get Price

Solar Cell: Working Principle & Construction (Diagrams Included)

Construction Details: Solar cells consist of a thin p-type semiconductor layer atop a thicker n-type layer, with electrodes that allow light penetration and energy capture.

Get Price

PVEducation

Most PV bulk silicon PV modules consist of a transparent top surface, an encapsulant, a rear layer and a frame around the outer edge. In most modules, the top surface is glass, th

Get Price

Microsoft PowerPoint

Solar cells are much more environmental friendly than the major energy sources we use currently. Solar cell reached 2.8 GW power in 2007 (vs. 1.8 GW in 2006) World''s market for solar cells

Get Price

Solar Panel Construction

Solar panels use photovoltaic cells, or PV cells for short, made from silicon crystalline wafers similar to the wafers used to make computer processors. The silicon wafers

Get Price

In-depth understanding of the composition of photovoltaic

In today''s era of pursuing clean energy and sustainable development, photovoltaic modules, as the key equipment for converting solar energy into electricity, have attracted much attention for

Get Price

Understanding the Composition of a Solar Cell

Learn about the makeup of solar cells and how they are used. Solar radiation is converted into direct current electricity by a photovoltaic cell, which is a semiconductor device.

Get Price

Photovoltaic (PV) Cell: Working & Characteristics

PV cells can be made from many different types of materials and be using a range of fabrication techniques. As shown in Figure 1, the major categories of

Get Price

In-depth understanding of the composition of photovoltaic modules

In today''s era of pursuing clean energy and sustainable development, photovoltaic modules, as the key equipment for converting solar energy into electricity, have attracted much attention for

Get Price

Photovoltaic cells

Photovoltaic cells (or solar cells) are the heart of solar power generation systems. They are little dowels pieced together into a mosaic that makes up a photovoltaic module (solar panel). Cell

Get Price

Solar panel

Solar panel Greencap Energy solar array mounted on brewery in Worthing, England Solar array mounted on a rooftop A solar panel is a device that

Get Price

Solar Photovoltaic Cell Basics

A thin-film solar cell is made by depositing one or more thin layers of PV material on a supporting material such as glass, plastic, or metal. There are two main types of thin-film PV

Get Price

Advanced polymer encapsulates for photovoltaic devices − A review

The efficiency of a PV module mainly depends on the PV cell technology and the lifetime of a PV cell under operation is a significant concern for the widespread

Get Price

What Are The Main Components of Solar Panels?

Suitable for N-type Topcon solar cells and dual-glass modules, EPE offers a balanced cost-performance ratio. Solar Cell Solar cells are what turn sunlight into power. They are the heart

Get Price

What Are Solar Panels Made Of and How Are They

Solar panels are usually made from a few key components: silicon, metal, and glass. Standard panels are either made from

Get Price

Photovoltaic Cell

Silicon photovoltaic cell, also referred to as a solar cell, is a device that transforms sunlight into electrical energy. It is made of semiconductor materials, mostly silicon, which in

Get Price

What Are Solar Panels Made Of and How Are They Made?

Solar panels are usually made from a few key components: silicon, metal, and glass. Standard panels are either made from monocrystalline or polycrystalline silicon. Start

Get Price

Cells, Modules, Panels and Arrays

Photovoltaic cells are connected electrically in series and/or parallel circuits to produce higher voltages, currents and power levels. Photovoltaic modules consist of PV cell circuits sealed in

Get Price

Perovskite solar cells

Metal halide perovskite solar cells are emerging as next-generation photovoltaics, offering an alternative to silicon-based cells. This Primer gives an overview of how to fabricate

Get Price

More related information

-

The composition of solar panel photovoltaic modules

The composition of solar panel photovoltaic modules

-

Maximum power of photovoltaic cell modules

Maximum power of photovoltaic cell modules

-

Photovoltaic cell arrays and photovoltaic modules

Photovoltaic cell arrays and photovoltaic modules

-

What are the cell types p and n in photovoltaic modules

What are the cell types p and n in photovoltaic modules

-

Photovoltaic double-glass cell modules

Photovoltaic double-glass cell modules

-

Photovoltaic cell modules in the Middle East

Photovoltaic cell modules in the Middle East

-

Thailand photovoltaic cell modules

Thailand photovoltaic cell modules

-

Photovoltaic cell module manufacturing in Tunisia

Photovoltaic cell module manufacturing in Tunisia

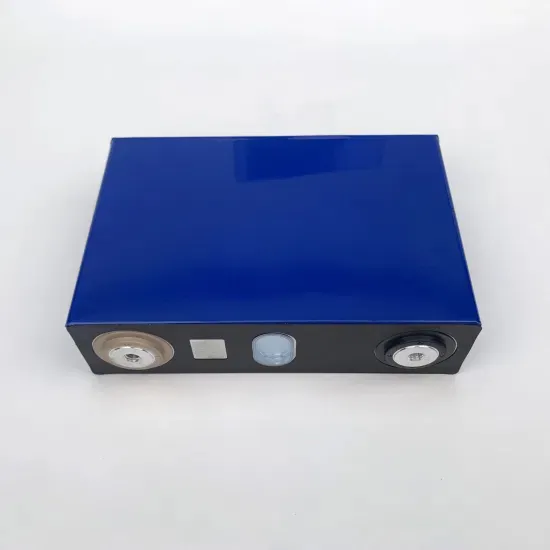

Commercial & Industrial Solar Storage Market Growth

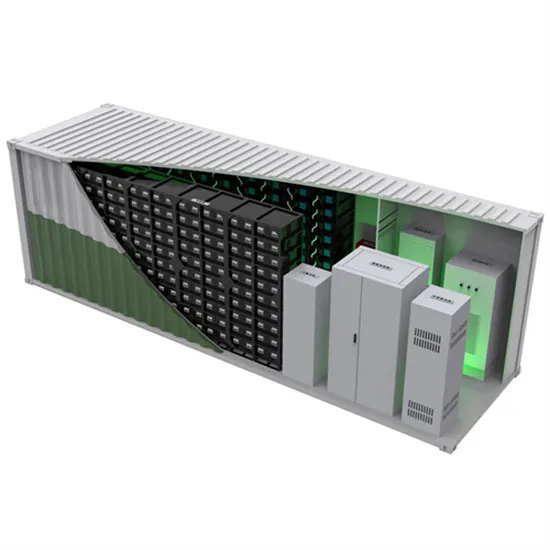

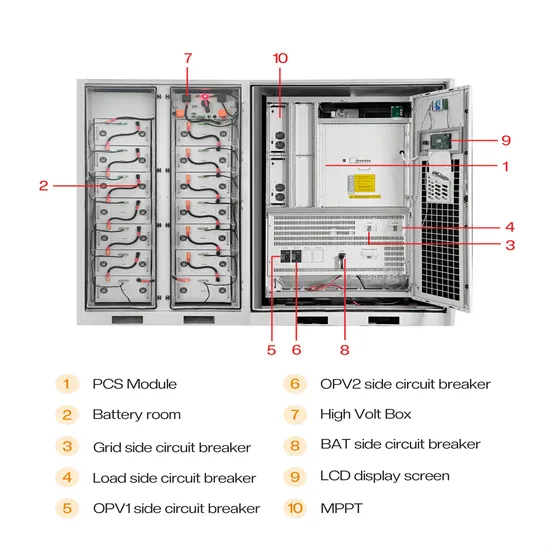

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.