Choosing the Right Lithium Ion Battery Cabinet: A Complete Guide

Ensure maximum safety and efficiency with this in-depth guide on selecting a lithium ion battery cabinet. Learn key features, regulations, and storage solutions to protect

Get Price

Setting Up a Lithium Battery Production Line: Cost, Process

Q2: What equipment is essential for lithium battery production? A2: Key equipment includes mixers, coating machines, drying ovens, assembly machines, and quality control labs.

Get Price

Behind the Scenes of Lithium Battery Production

This article dives into the key stations and equipment that make up a lithium battery pack production line.

Get Price

UPS Battery Cabinet Upgrade, Retrofit, Replacement

Equipment End of Life Considerations: UPS Batteries and Battery Cabinets When an Uninterruptible Power Supply (UPS) nears its end of life, this is a very common time to

Get Price

Fire Protection for Lithium-ion Battery Energy Storage

As overall demand for energy increases in our modern world – so does the use of renewable sources like wind and solar. As the use of these variable sources of energy grows – so does

Get Price

Justrite Lithium Ion Battery Storage Charging Cabinet,

The lightweight, benchtop design makes it easy to move the cabinet wherever you need it. Lockable doors keep your lithium-ion batteries

Get Price

Key Processes and Equipment for Lithium Battery Cell

For the middle-stage processes, the equipment includes die-cutting machines, winding machines, stacking machines, and electrolyte

Get Price

Explosion-proof measures for battery cabinets during production

Explosion-Proof Lithium Battery Effectively Reduces the Risk of Fire Or Explosion during Charging and Discharging of Lithium Battery through Safety Design, Strict Manufacturing, Quality

Get Price

Configuring the Perfect System for Lithium-ion Battery

Production systems and equipment for manufacturing Lithium-ion battery cells. Safe, efficient cathode and anode powder handling for the

Get Price

Battery cabinets

As lithium-ion batteries can pose major hazards (e.g. in the form of a battery fire), battery cabinets differ fundamentally in their design - on the one hand in fireproof battery cabinets and in simple

Get Price

Understanding the Lithium

In large - scale battery manufacturing plants, lithium - battery aging cabinets are an essential part of the production line. They are used to age batteries before they are shipped to

Get Price

Lithium Battery Charging Cabinet: The Essential Guide to Safe

The electrolyte solution in most lithium-ion batteries is highly flammable. Any rupture or internal damage can lead to leakage and ignition, further increasing the need for

Get Price

Key Processes and Equipment for Lithium Battery Cell Production

For the middle-stage processes, the equipment includes die-cutting machines, winding machines, stacking machines, and electrolyte injection machines. The back-end

Get Price

Understanding Forklift Battery Charging Station Safety

Forklift battery charging stations are critical to the operational efficiency of warehouses, manufacturing facilities, and any business that relies

Get Price

Lithium Battery PACK Production Line Processes and Equipment

The Lithium Battery PACK production line encompasses processes like cell selection, module assembly, integration, aging tests, and quality checks, utilizing equipment such as laser

Get Price

Setting Up a Lithium Battery Production Line: Cost, Process & Equipment

Q2: What equipment is essential for lithium battery production? A2: Key equipment includes mixers, coating machines, drying ovens, assembly machines, and quality control labs.

Get Price

5 steps to your new lithium-ion battery production line

We created a detailed checklist on all relevant information to clarify your lithium-ion or sodium-ion battery manufacturing equipment. All 5 mentioned steps are broke down to a detailed list that

Get Price

What is Lithium Battery Cleanroom?

2. Do lithium battery cleanrooms need to comply with any specific industry standards (e.g. cleanroom classification according to ISO 14644-1)? ISO 14644-1 regulation is

Get Price

19-Inch Lithium Battery Cabinets for 4G/5G – KDST

In modern communication base stations, battery cabinets play a crucial role as the key equipment to ensure uninterrupted operation of communication networks. And lithium batteries, especially

Get Price

Choosing the Right Lithium Ion Battery Cabinet: A

Ensure maximum safety and efficiency with this in-depth guide on selecting a lithium ion battery cabinet. Learn key features, regulations, and

Get Price

Lithium Battery Production Process and Key Equipment

This station is where the positive and negative electrodes, along with a separator, are laminated together to form individual battery cells. The key equipment

Get Price

Configuring the Perfect System for Lithium-ion Battery Production

Production systems and equipment for manufacturing Lithium-ion battery cells. Safe, efficient cathode and anode powder handling for the battery industry.

Get Price

What are the lithium battery production equipment?

According to the production process of lithium-ion batteries, lithium battery equipment can be mainly divided into front-end equipment, mid-end equipment and back-end equipment.

Get Price

Choosing the Right Battery Storage Cabinet: A

Lithium-ion batteries have become indispensable across countless industries, from logistics and warehousing to construction and renewable

Get Price

19-Inch Lithium Battery Cabinets for 4G/5G – KDST

For communication base stations, with the growth of business and technology upgrades, the power demand of base station equipment may also increase.

Get Price

Preventing Fire and/or Explosion Injury from Small and

Workers who wear or frequently handle lithium-powered devices or batteries are particularly at risk if a lithium battery catches fire or explodes since the device or battery is close to the body.

Get Price

What are the lithium battery production equipment?

According to the production process of lithium-ion batteries, lithium battery equipment can be mainly divided into front-end equipment, mid-end

Get Price

Battery Manufacturing Process: Materials, Production

The battery manufacturing process is a complex sequence of steps transforming raw materials into functional, reliable energy storage units. This

Get Price

Battery Production | Lithium-ion & EV Battery Manufacturing Equipment

Battery manufacturing equipment refers to the machines and systems used for battery production, fabrication, assembly, and testing. This complex process may require the use of coating

Get Price

Battery Production | Lithium-ion & EV Battery Manufacturing

Battery manufacturing equipment refers to the machines and systems used for battery production, fabrication, assembly, and testing. This complex process may require the use of coating

Get Price

Lithium Battery Production Process and Key Equipment

This station is where the positive and negative electrodes, along with a separator, are laminated together to form individual battery cells. The key equipment here includes sheet lamination

Get Price

6 FAQs about [What production equipment does the lithium battery station cabinet need ]

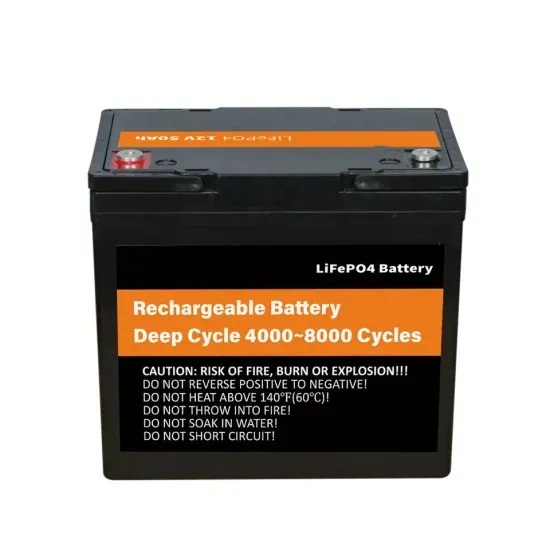

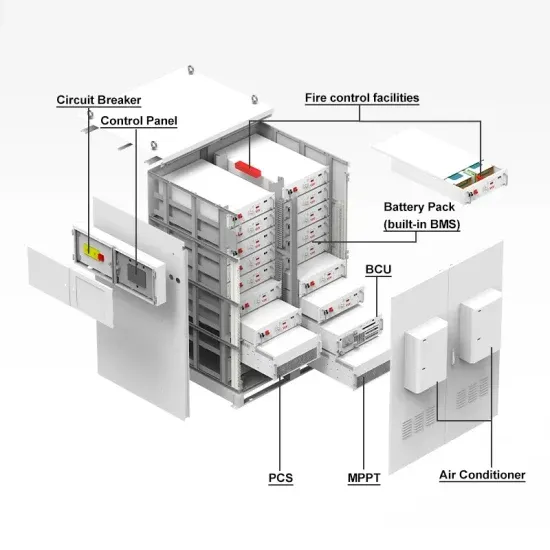

What is a lithium-ion battery storage cabinet?

A lithium-ion battery storage cabinet is a secure containment and charging solution specifically designed by DENIOS for Lithium-Ion batteries. These cabinets offer comprehensive safeguarding, including 90-minute fire resistance against external sources.

Why should you invest in a lithium ion battery cabinet?

Emerging technologies will enhance both the intelligence and reliability of charging cabinets in industrial settings. The right lithium ion battery cabinet is a vital investment for any business using rechargeable power systems. It protects against fire, enhances compliance, and streamlines operations.

Why are specialized lithium battery storage cabinets important?

Here’s why specialized lithium battery storage cabinets are critical: Most traditional cabinets are fire-rated only for external fire resistance. Lithium-ion battery incidents often originate internally, requiring fireproof battery charging cabinets that can withstand internal fires for at least 90 minutes.

What are lithium ion battery cabinet solutions?

To mitigate these risks, industries and institutions are turning to advanced lithium ion battery cabinet solutions. These cabinets are specially designed to safeguard against internal fires, thermal runaway, and mechanical damage. Standard storage methods are often inadequate for lithium-ion technology.

Why do you need a lithium battery charging cabinet?

These cabinet charger systems reduce workplace clutter, prevent unauthorized access, and centralize power needs in one fireproof location. A proper lithium battery charging cabinet should support multiple battery sizes, offer safe access points, and isolate thermal events to a single compartment. Regulations often lag behind technology.

What makes a good battery storage cabinet?

Therefore, battery storage cabinets should feature integrated ventilation to expel heated air and maintain a stable internal temperature. A good battery charging cabinet doubles as a charging station. It must include: Factory-installed socket strips This minimizes the need for retrofitting and ensures safety from the outset.

More related information

-

Balkan Peninsula lithium battery station cabinet production integrated system

Balkan Peninsula lithium battery station cabinet production integrated system

-

Lithium battery station cabinet factory production standards

Lithium battery station cabinet factory production standards

-

Lithium battery station cabinet base station energy equipment market price

Lithium battery station cabinet base station energy equipment market price

-

What are the lithium battery station cabinet manufacturers in Mauritius

What are the lithium battery station cabinet manufacturers in Mauritius

-

Make lithium battery station cabinet

Make lithium battery station cabinet

-

What brands of lithium battery station cabinets are available

What brands of lithium battery station cabinets are available

-

How much does it cost to replace the lithium battery station cabinet in Sierra Leone

How much does it cost to replace the lithium battery station cabinet in Sierra Leone

-

Lithium battery station cabinet fire protection system ESS power base station

Lithium battery station cabinet fire protection system ESS power base station

Commercial & Industrial Solar Storage Market Growth

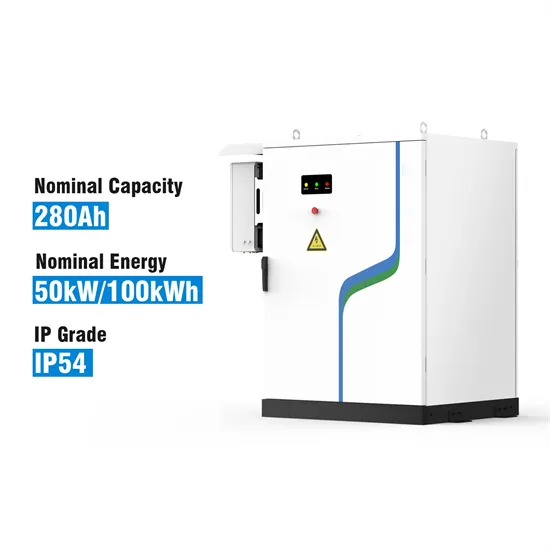

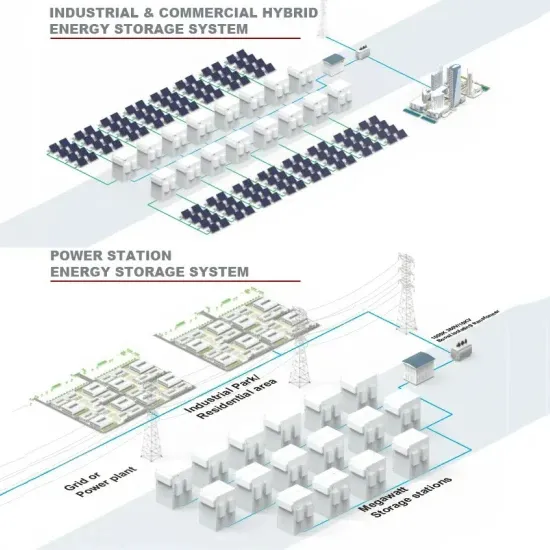

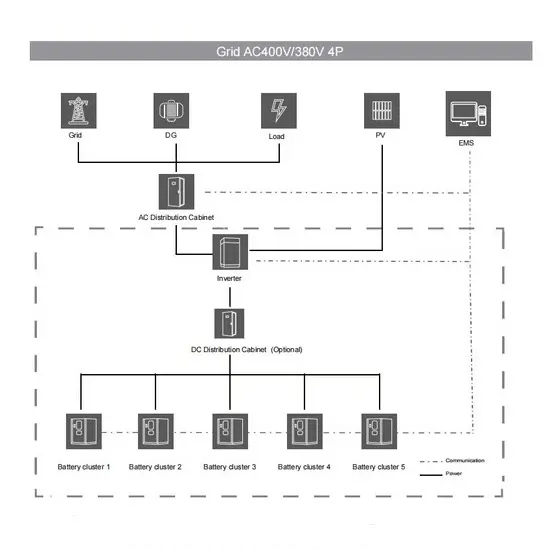

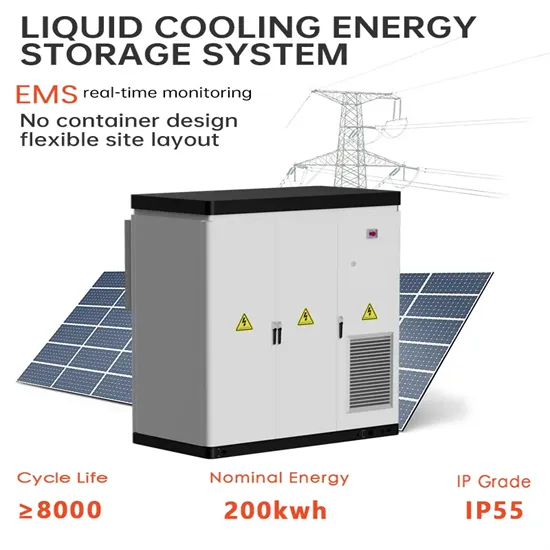

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.