Explosion-proof standards for battery energy storage cabinets

Why do energy storage containers, industrial and commercial energy storage cabinets, and energy storage fire protection systems need explosion-proof f y oil-damped door closers,

Get Price

CLASSIFICATION OF LOCATIONS FOR ELECTRICAL

This difference explains why Class I, Division 1 equipment can be called explosion-proof, and Class II equipment is called dust-ignition proof. Class II equipment has a different set of

Get Price

Kleev''s Comprehensive Explosion-Proof Enclosure

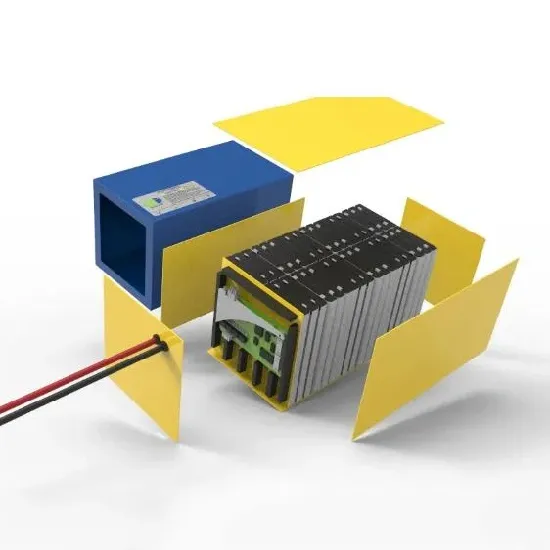

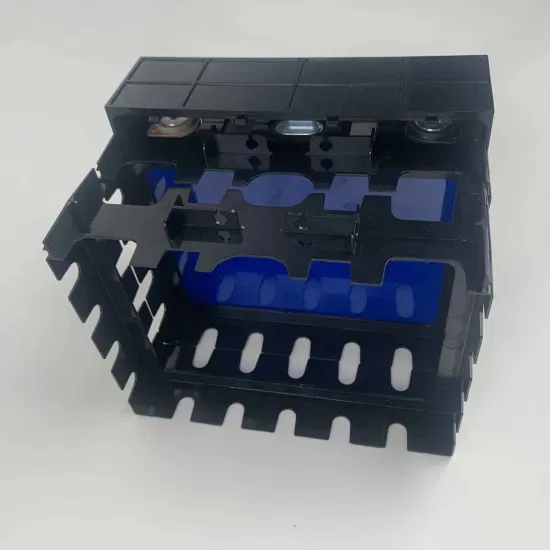

Battery Boxes One of the latest additions to Kleev''s product range is explosion-proof battery boxes. These are particularly designed for energy storage

Get Price

What is the explosion-proof distance of the energy storage power station?

Determining the appropriate explosion-proof distance involves a multitude of factors. Key among these are the types of substances stored, the quantity of energy retained,

Get Price

LED floodlight explosion proof: energy storage industry safety

First, why the energy storage industry must deploy LED floodlight explosion proof? Along with the global new energy installed capacity exceeded 3,000GW [IEA 2023 data], energy storage

Get Price

Energy Storage NFPA 855: Improving Energy Storage

The focus of the following overview is on how the standard applies to electrochemical (battery) energy storage systems in Chapter 9 and specifically on lithium-ion (Li-ion) batteries.

Get Price

Electrical Area Classification in Coal-Fired Power Plants

There are many potential fire sources in a coal plant. Clearly defining electrical areas and their applicable codes can make fire prevention much simpler.

Get Price

requirements for planning and design of energy storage power stations

By interacting with our online customer service, you''ll gain a deep understanding of the various requirements for planning and design of energy storage power stations featured in our

Get Price

Siting and Safety Best Practices for Battery Energy Storage

NFPA 855 (Standard for the Installation of Stationary Energy Storage Systems): Provides the minimum requirements for mitigating the hazards associated with BESS.

Get Price

What is the explosion-proof distance of the energy

Determining the appropriate explosion-proof distance involves a multitude of factors. Key among these are the types of substances stored, the

Get Price

Battery Room Ventilation Code Requirements

Battery room ventilation codes and standards protect workers by limiting the accumulation of hydrogen in the battery room. Hydrogen release is

Get Price

White Paper Ensuring the Safety of Energy Storage Systems

Ensuring the Safety of Energy Storage Systems Thinking about meeting ESS requirements early in the design phase can prevent costly redesigns and product launch delays in the future.

Get Price

Understanding NFPA 855 Standards for Lithium

NFPA 855 lithium battery standards ensure safe installation and operation of energy storage systems, addressing fire safety, thermal runaway,

Get Price

Explosion Control Guidance for Battery Energy Storage

codes and standards, such as NFPA 855, NFPA 68, and NFPA 69. NFPA 855 is the main standard for the installation of stationary ESS, which provides the minimum requirements for

Get Price

What is "Explosion Proof" and When is it Needed?

Explosion Proof (EP) is a crucial requirement for equipment intended for use in hazardous (classified) locations, as stipulated by the National Electrical Code, NFPA 70,

Get Price

Large-scale energy storage system: safety and risk

The International Renewable Energy Agency predicts that with current national policies, targets and energy plans, global renewable energy

Get Price

CLOU Aqua-C3.0 Pro: Practical Energy Storage

2 days ago· Field Performance CLOU''s Aqua-C3.0 Pro has been deployed in several large-scale projects, including the first large lithium-ion ESS project in Indiana, the largest storage power

Get Price

Energy Storage Fire Suppression Systems | EB BLOG

Natural disasters such as lightning strikes, floods, and earthquakes can damage equipment in energy storage power stations, leading to

Get Price

Explosion-proof standards for battery energy storage cabinets

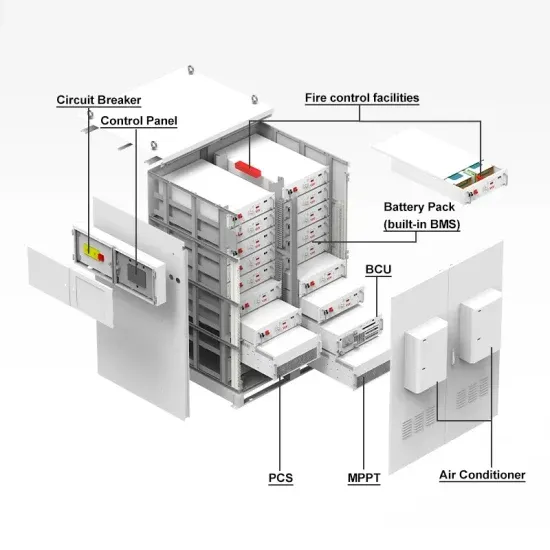

Both the exhaust ventilation requirements and the explosion control requirements in NFPA 855, Standard for Stationary Energy Storage Systems, are designed to mitigate hazards associated

Get Price

Battery Energy Storage Systems: Main Considerations for Safe

Battery Energy Storage Systems: Main Considerations for Safe Installation and Incident Response Battery Energy Storage Systems, or BESS, help stabilize electrical grids by

Get Price

When to Choose Intrinsically Safe vs. Explosion-Proof Equipment

Discover the key differences between intrinsically safe and explosion-proof equipment to ensure optimal safety in hazardous environments. Learn which protection

Get Price

Understanding NFPA 855 Standards for Lithium Battery Safety

NFPA 855 lithium battery standards ensure safe installation and operation of energy storage systems, addressing fire safety, thermal runaway, and compliance.

Get Price

White Paper on Active Ventilation Explosion-Proof System

This outcome validates both the fire containment capability of CLOU''s BESS and the safety reliability of the ThermoFlux Active Ventilation Explosion-Proof System in high-density station

Get Price

Battery Energy Fire Explosion Protection

Battery Energy Storage Systems Fire & Explosion Protection While battery manufacturing has improved, the risk of cell failure has not disappeared. When a cell fails, the main concerns are

Get Price

6 FAQs about [Requirements for explosion-proof energy storage power stations]

What are the energy storage operational safety guidelines?

In addition to NYSERDA’s BESS Guidebook, ESA issued the U.S. Energy Storage Operational Safety Guidelines in December 2019 to provide the BESS industry with a guide to current codes and standards applicable to BESS and provide additional guidelines to plan for and mitigate potential operational hazards.

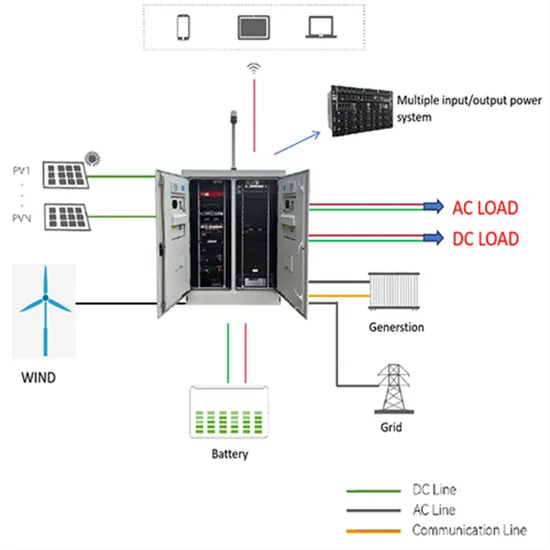

What are the different types of explosion control options for ESS?

The two types of explosion control options for ESS, NFPA 68 deflagration venting and NFPA 69 exhaust ventilation, are based on a design basis determined from UL 9540A test data. This testing is meant to provide baseline data for the analysis and is generally extrapolated to a sufficiently conservative hazard scenario for the ESS installation.

Do you need documentation before entering a battery room?

It is a requirement to have all the documentation in place prior to authorized personnel entering a battery room to perform a specific work task on a battery system under normal operating conditions. However, it is likely the employee will need to enter the battery room to deal with a battery system that is not operating normally.

Should deflagration venting be used as passive explosion protection?

In general, using deflagration venting as passive explosion protection in addition to an active system has multiple benefits due to the nature of the battery failure event, which involves a rapid release of flammable gases.

How does ESS design affect fire and explosion safety?

Several competing design objectives for ESS can detrimentally affect fire and explosion safety, including the hot aisle/cold aisle layout for cooling efficiency, protection against water and dust ingress into the enclosure, and the use of larger cells with increased energy density.

Can passive protection be used as a sole explosion protection scheme?

The two main challenges in using passive protection methodology are design constraints for the enclosure and lack of validation data to support calculation methodology. These challenges make it difficult to obtain a feasible design for deflagration venting of ESS enclosures as the sole explosion protection scheme for most configurations.

More related information

-

What are the requirements for independent energy storage power stations

What are the requirements for independent energy storage power stations

-

Configuration requirements for energy storage power stations

Configuration requirements for energy storage power stations

-

What are the factory energy storage power stations

What are the factory energy storage power stations

-

Questions about energy storage power stations

Questions about energy storage power stations

-

Which companies have energy storage power stations in Colombia

Which companies have energy storage power stations in Colombia

-

What are the photovoltaic energy storage power stations in Argentina

What are the photovoltaic energy storage power stations in Argentina

-

What are the wind power energy storage power stations

What are the wind power energy storage power stations

-

Load characteristics of power grid energy storage stations

Load characteristics of power grid energy storage stations

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.