Lithium battery module design production process and

This article will introduce you to the characteristics, design and production process, key points, and development trend of lithium battery module structure

Get Price

Key Points of Lithium Battery PACK Manufacturing

From selecting and matching battery cells to assembling, testing, and packaging, discover the key steps involved in creating high-quality lithium

Get Price

Battery Electric | Volvo Group

The building blocks: lithium-ion cells Lithium-ion cells are a common choice for vehicle battery packs. Lithium is what is referred to as the "energy carrier" in

Get Price

Lithium-Ion Battery Pack Manufacturing Process Guide

The process of lithium-ion battery pack manufacturing involves meticulous steps from cell sorting to final testing and assembly. Each phase plays a critical role in ensuring the

Get Price

Production Process of Battery Modules and Battery

Acknowledgements to Simon Lind ner for his assistance in creating the illustrations and contents. presents the process chain for the

Get Price

PRODUCTION PROCESS OF BATTERY MODULES AND

The publication "Production process of a lithium-ion battery cell" provides a comprehensive process overview of the production of different battery cell formats from electrode

Get Price

Flexible Product Architecture and Production Process of Lithium

The vehicle drive train electrification constitutes a fundamental change of the automotive sector and poses severe challenges for established companies. Particularly the introduction of the

Get Price

Voltage-correlation based multi-fault diagnosis of lithium-ion battery

In this paper, a multi-fault diagnostic method based on correlation coefficients and the variation in voltage difference was presented for series-connected lithium-ion battery packs.

Get Price

Lithium Battery Pack manufacturing Production Line

3 days ago· A lithium battery pack manufacturing production line is designed to efficiently produce highquality lithiumion or lithium ferro phosphate (LFP) battery packs, which are

Get Price

Custom Lithium Battery Pack Manufacturing

Manufacturing custom lithium-ion battery packs requires precise engineering, quality control, and safety standards. The process involves gathering

Get Price

An active equalization strategy for series-co | EurekAlert!

A paper describing the equalization control strategy of lithium battery pack with dual threshold triggering mechanism and path optimization function was published in the

Get Price

Naxtra Battery Breakthrough & Dual-Power

CATL''s Naxtra Battery breaks through the performance boundaries of the material itself, achieving the mass production of sodium-ion batteries for

Get Price

What Is a Dual Battery System? Lithium Setup & Safety Guide

Vade Battery''s lithium-ion battery packs are engineered for vibration resistance and can be mounted in confined spaces, making them ideal for dual-system installations.

Get Price

The Manufacturing Process of Lithium Batteries

In the lithium battery manufacturing process, electrode manufacturing is the crucial initial step. This stage involves a series of intricate processes that

Get Price

Current and future lithium-ion battery manufacturing

Lithium-ion batteries (LIBs) have been widely used in portable electronics, electric vehicles, and grid storage due to their high energy density, high power density, and long cycle

Get Price

Lithium-Ion Battery Pack Manufacturing Process Guide

The process of lithium-ion battery pack manufacturing involves meticulous steps from cell sorting to final testing and assembly. Each phase

Get Price

Grouping optimization of dual-system mixed lithium-ion battery

An electrochemical-thermal coupling model of the dual-system battery pack is established and experimentally validated. Four distinct structural designs for dual-system

Get Price

Lithium Battery PACK Production Line Processes and

The Lithium Battery PACK line is a crucial part of the lithium battery production process, encompassing cell assembly, battery pack structure design,

Get Price

American Lithium Battery Manufacturing | Custom

Automation Built for Every Step of Production Our process begins with custom-configured assembly lines designed around your product. We use robotics,

Get Price

Naxtra Battery Breakthrough & Dual-Power Architecture: CATL

The dual-power architecture means that the battery pack has two powerful "independent energy zones," which enables five dual functions: dual high-voltage, dual low

Get Price

Advanced lithium-ion battery process manufacturing equipment

Lithium-ion battery cell manufacturing depends on a few key raw materials and equipment manufacturers. Battery manufacturing faces global challenges and opportunities as

Get Price

From Raw Materials to Finished Product: The Lithium

In the lithium-ion battery pack production plant, there is a vast amount of lithium battery science to know, combined with the huge

Get Price

Custom Lithium Battery Pack Manufacturing

Manufacturing custom lithium-ion battery packs requires precise engineering, quality control, and safety standards. The process involves gathering requirements, selecting cells, concurrent

Get Price

Production Process of Battery Modules and Battery Packs

Acknowledgements to Simon Lind ner for his assistance in creating the illustrations and contents. presents the process chain for the production o f batter y modules and batter y

Get Price

Lithium-ion Battery Pack Manufacturing Process & Design

This guide discussed the lithium battery pack anufacturing process, battery pack design, and the impact of technological advancements.

Get Price

Naxtra Battery Breakthrough & Dual-Power Architecture: CATL

CATL''s Naxtra Battery breaks through the performance boundaries of the material itself, achieving the mass production of sodium-ion batteries for the first time.

Get Price

Key Points of Lithium Battery PACK Manufacturing Process

From selecting and matching battery cells to assembling, testing, and packaging, discover the key steps involved in creating high-quality lithium-ion battery packs.

Get Price

6 FAQs about [Production of dual lithium battery packs]

What is the production process of lithium-ion battery cells?

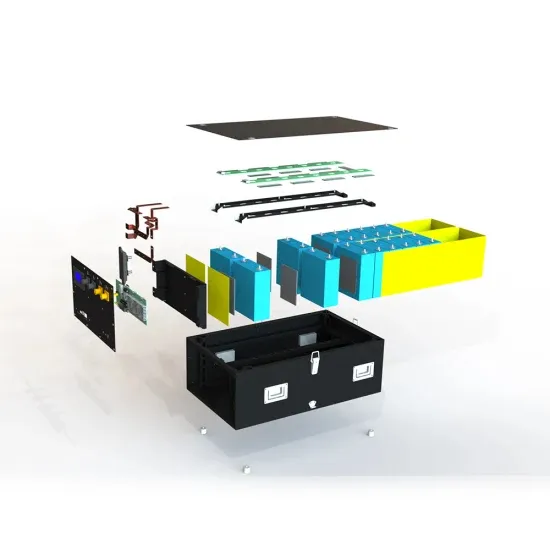

"Production process of lithium-ion battery cells" , this brochure presents the process chain for the production of battery modules and battery packs. ● The individual cells are connected in series or parallel in a module. Several modules and other electrical, mechanical and thermal components are assembled into a pack. Battery value chain

What is the battery pack manufacturing process?

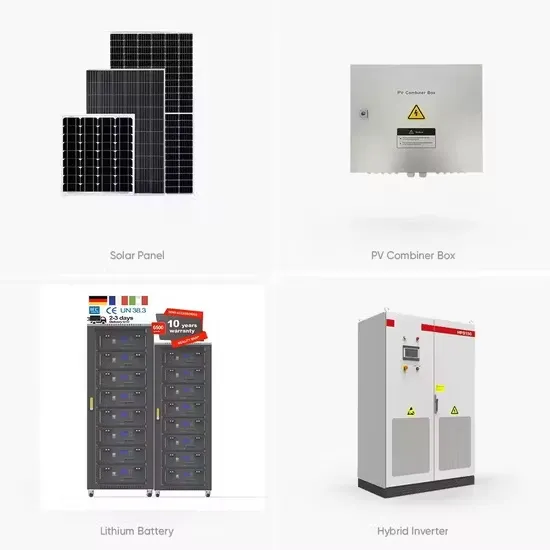

The battery pack manufacturing process involves cell selection, module assembly, wiring, thermal management, and safety integration. Each step ensures efficiency, reliability, and durability. Understanding this process helps manufacturers optimize production, clients get tailored solutions, and consumers receive safer, longer-lasting batteries.

What is a lithium ion battery pack?

A battery pack consists of multiple cells connected in series or parallel. How to make lithium-ion batteries? It’s always been an interesting topic. The production of lithium-ion batteries is a complex process, totaling Three steps. The cell sorting stage is a critical step in ensuring the consistent performance of lithium-ion batteries.

How are lithium ion batteries made?

The production of lithium-ion battery cells primarily involves three main stages: electrode manufacturing, cell assembly, and cell finishing. Each stage comprises specific sub-processes to ensure the quality and functionality of the final product. The first stage, electrode manufacturing, is crucial in determining the performance of the battery.

What makes a custom lithium-ion battery pack unique?

The foundation of any custom lithium-ion battery pack lies in the selection of the integrated cells. Our cell selection for custom packs involves: Lithium-ion cell advancements continue expanding performance boundaries yearly. Leveraging state-of-the-art cell technology is crucial for maximizing custom pack capabilities.

What equipment is used in lithium battery manufacturing?

Mixers, coating and drying machines, calendaring machines, and electrode cutting machines are some of the essential lithium battery manufacturing equipment employed during this process. During the cell assembly stage of the lithium battery manufacturing process, we carefully layer the separator between the anode and cathode.

More related information

-

Specialized production of lithium battery packs

Specialized production of lithium battery packs

-

32650 Production of lithium battery packs

32650 Production of lithium battery packs

-

Gambia where lithium battery packs are assembled

Gambia where lithium battery packs are assembled

-

How many lithium battery packs can be connected in parallel

How many lithium battery packs can be connected in parallel

-

Djibouti produces polymer lithium battery packs

Djibouti produces polymer lithium battery packs

-

Lithium battery pack production in Western Europe

Lithium battery pack production in Western Europe

-

Three-series and four-parallel lithium battery production

Three-series and four-parallel lithium battery production

-

How much does it cost to purchase lithium battery packs

How much does it cost to purchase lithium battery packs

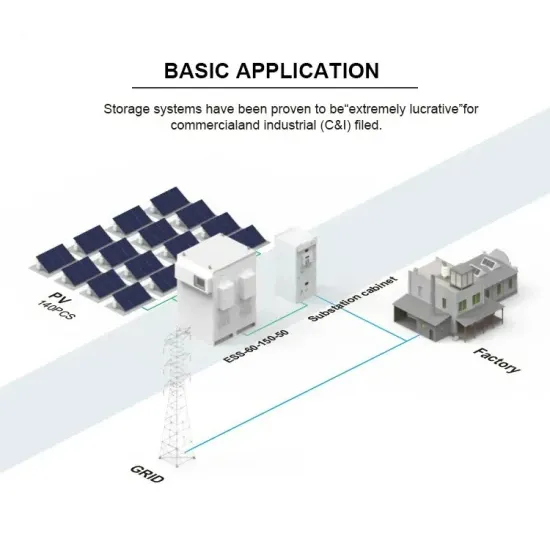

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.