Underground Mine Communications Infrastructure

This guideline will provide high-level guidance for the complete lifecycle (designing to decommissioning) of underground mine

Get Price

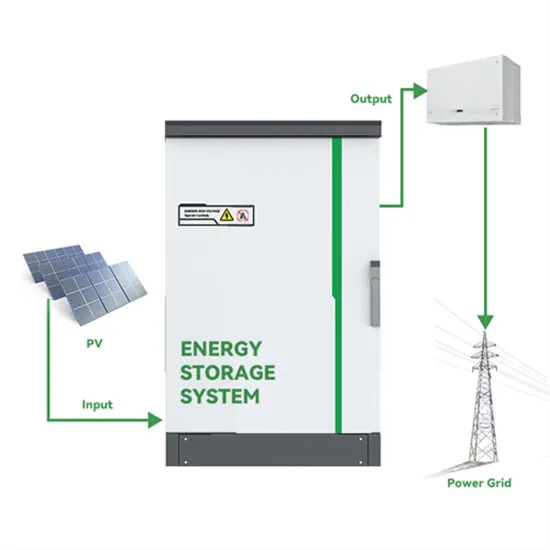

Communication Base Station Inverter Application

The power requirements of inverters for communication base stations vary depending on the size of the site, equipment requirements and

Get Price

Expert Mine Electrician: Coal Mining Communications

Working closely with system architects, mine electricians determine the best locations to install routers, base stations, and emergency communication lines. Data analytics plays a vital role in

Get Price

A Medium Frequency Wireless Communication System For Underground Mines

An underground medium frequency radio communications system has been developed and demonstrated in both coal and metal/non metal mines. The principal advantage of the system

Get Price

SMART UNDERGROUND COMMUNICATIONS

SYSTEM OPERATION The system is designed to provide seamless two-way communications throughout an underground mine or tunnel. This is achieved through the use of Leaky Feeder

Get Price

Shendong''s First 5G Low-Frequency Intrinsic Safety Base Station

On September 26, Shendong Coal''s Cuncaota Coal Mine integrated its steel wire rope inspection robot for the No.22 main coal transportation system with a newly-deployed 5G

Get Price

Underground Mine Communications Infrastructure Guideline

This guideline will provide high-level guidance for the complete lifecycle (designing to decommissioning) of underground mine communications infrastructure. It will be targeted to

Get Price

Mining Communication Base Station

High power & long-range mining communication base stations designed for your needs, call us to discuss mining base station requirements.

Get Price

Communications Solutions

IWT''s cutting-edge SENTINEL™ Communication System is designed for the unique demands of underground mining and tunneling. IWT networks provide an unparalleled range of features

Get Price

Mine Communication System Installation: What to Expect

In this blog post, we''re breaking down what the installation of a Mine Communication System looks like—step-by-step—so you can feel prepared, informed, and

Get Price

Expert Mine Electrician: Coal Mining Communications

In this comprehensive guide, we will explore the multifaceted responsibilities of a mine electrician in the coal mining industry, with a focus on how modern business intelligence and data

Get Price

(PDF) Communications Challenges in Underground

In underground mines, the need of wireless communications has evolved from maximising productivity, following up, monitoring, and

Get Price

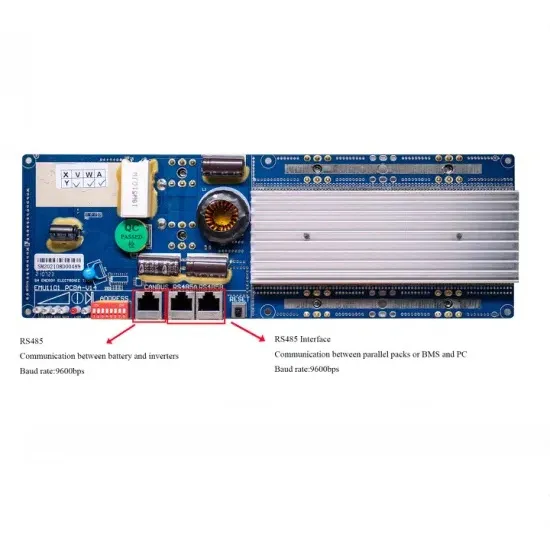

Communication Base Station Energy Power Supply System

The wind-solar-diesel hybrid power supply system of the communication base station is composed of a wind turbine, a solar cell module, an integrated controller for hybrid energy

Get Price

G U I D E L I N E

D I S C L A I M E R The compilation of information contained in this document relies upon material and data derived from a number of third party sources and is intended as a guide only

Get Price

CDC

A leaky feeder communications system uses underground hand-held radios that communicate with a radio transceiver (base station), which is usually located on the surface at

Get Price

Underground Mine Communications Infrastructure

It provides the reader with an overview of the planning and design recommendations for underground communications development, some of the best practices used within mining

Get Price

Installation Guide

If a site is near a pollution source, it is 1500–3000 m away from heavy pollution sources, such as smelteries, coal mines, and thermal power plants; 1000–2000 m away from medium pollution

Get Price

Mine Communication Technique | SpringerLink

Mining, being a dynamic and intricate operation, needs a multifaceted continuous stream of information from surface to underground

Get Price

CN115968061A

The invention relates to the technical field of communication equipment in a coal mine, in particular to a mobile communication base station used in the coal mine.

Get Price

Design and implementation of mine-used integrated base station

Based on the characteristics of intelligent mines, this study deeply analyzes the 5G network topology, and integrates the BBU base station controller, PB base station aggregator, and

Get Price

How Mine Communication Networks Improve Production

Studies of the physical characteristics of underground mines reveal the impact on which communication systems will be used for underground mining. Regardless of whether it is a

Get Price

Underground Mine Communications, Control and Monitoring

In small mines and belt-haulage-type mines the communication center may be the responsibility of the hoist engineer, the supply man, or the maintenance foreman.

Get Price

mine communication systems

Designed to monitor the integrity of the ground circuit of power distribution circuits in coal mines. Either the three-phase wires or a pilot wire can be used as a return signal path for the Ground

Get Price

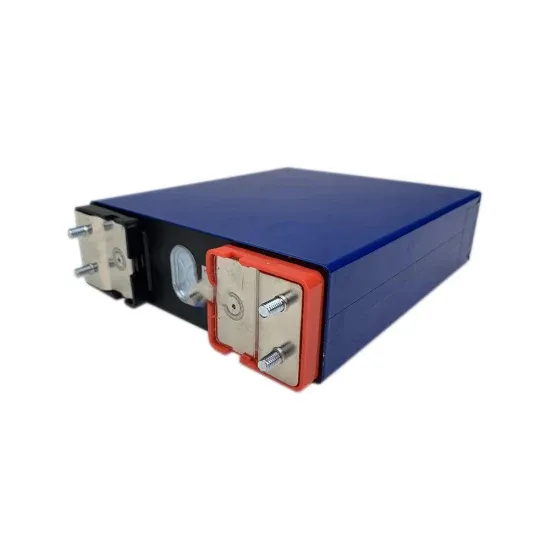

Mining Explosion-Proof Equipment,Mine Inverter,Mine Starter

Mining explosion-proof and intrinsically safe type multi-loop high-voltage vacuum electromagnetic starter is suitable for coal mine AC 3300V, frequency 50Hz, three-phase neutral point

Get Price

6 FAQs about [Installation of communication base station inverter in coal mine]

What is a mining communication base station?

Our mining communication base stations are innovatively built to fit your specific project’s needs. Our semi-portable LTE base stations are modular, standalone, fully self-supporting units forging the way in long range communications solutions for remote mining operations. Mining relies on communication technology.

Can a mining base station be used as a communications tower?

Our mining communication base stations can also host mast systems up to 32 metres high, depending on your selected model, meaning it can easily be used as an off-grid communications tower. Or use our base station next to a fixed tower for power and communications without the need for site services.

Can a mining base station be used as an off-grid communications tower?

Quick to deploy and ideal for harsh and rugged environments, it will be up and running in its desired location in no time at all. Our mining communication base stations can also host mast systems up to 32 metres high, depending on your selected model, meaning it can easily be used as an off-grid communications tower.

How are video communication systems used in underground mines?

Video communication systems are used in monitoring and safety alert systems throughout underground mines (Table 7). Wi-Fi or closed-circuit television (CCTV) are a commonly used system to monitor mining activity. Monitor-ing devices transmit a visual signal from areas where risk exists for personnel, equipment operation, or interactions 1.

What is the communication infrastructure in an underground mining environment?

The communication infrastructure in an underground mining environment will use mainly layers 1–4. The overall performance of a communication system is dependent on the characteristics/performance of each indi-vidual layer; one layer may limit the performance of the over-all system, or of a specific application for which the system is built.

What is a communication base station?

Communication base station setups will usually include a wide array of different technologies, including power supplies, data servers, head end, radio repeaters, and communication systems that allow for high-speed continuous information flow. It can also be used as part of a leaky feeder system in the communication network.

More related information

-

Communication base station inverter installation subcontract

Communication base station inverter installation subcontract

-

Installation cost of communication base station inverter

Installation cost of communication base station inverter

-

Photovoltaic communication base station inverter company

Photovoltaic communication base station inverter company

-

How is Huawei s communication base station inverter

How is Huawei s communication base station inverter

-

Communication base station inverter 900 power generation

Communication base station inverter 900 power generation

-

Yaounde 5G communication base station inverter grid-connected project

Yaounde 5G communication base station inverter grid-connected project

-

Communication base station inverter grid-connected intelligent splitter

Communication base station inverter grid-connected intelligent splitter

-

Is the communication base station inverter lightning-proof and safe

Is the communication base station inverter lightning-proof and safe

Commercial & Industrial Solar Storage Market Growth

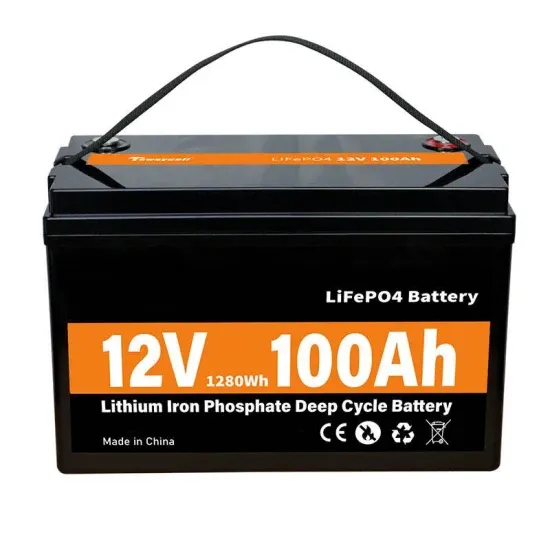

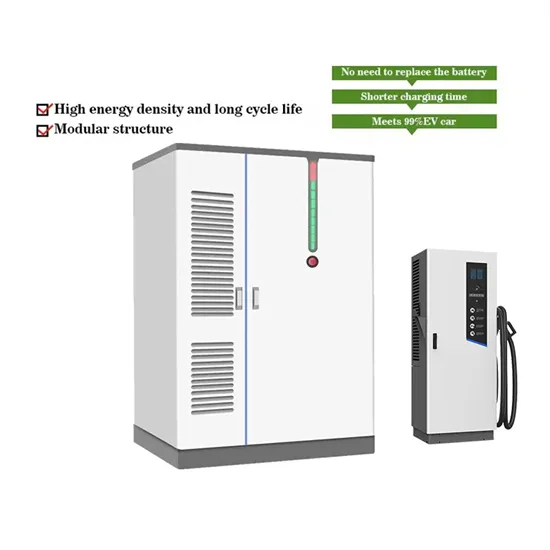

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.