Everything You Need to Know About Solar Inverter

A PV to inverter power ratio of 1.15 to 1.25 is considered optimal, while 1.2 is taken as the industry standard. This means to calculate the perfect inverter

Get Price

Solar Inverter Sizing Guide for Maximum Efficiency

In most cases, the inverter size should be close to the size of your solar panel system, within a 33% ratio. For example, a 6.6kW solar array often

Get Price

Solar Inverter Sizing Guide for Maximum Efficiency | Mingch

In most cases, the inverter size should be close to the size of your solar panel system, within a 33% ratio. For example, a 6.6kW solar array often pairs with a 5kW inverter to

Get Price

What DC to AC inverter load ratio is ideal for your

The DC to AC ratio (also known as the Inverter Load Ratio, or "ILR") is an important parameter when designing a solar project. For example, a 6

Get Price

The capacity ratio of photovoltaic power plants

The term ''capacity ratio'' is certainly unfamiliar to laypeople. Capacity ratio refers to the ratio of the nominal power of components in a

Get Price

Solar plants typically install more panel capacity

For economic and engineering reasons, capacity values reported in DC typically are 10% to 30% higher than those reported in AC capacity.

Get Price

Review of state-of-the-art: Inverter-to-array power ratio for thin

Numerous sizing methodology for the combination of inverter and PV array components have appeared in the literature including guidelines and third-party field studies.

Get Price

Performance ratio

Specifically, the performance ratio is the ratio of the actual and theoretically possible energy outputs. It is largely independent of the orientation of a PV plant and the incident solar

Get Price

Life-Cycle Cost and Optimization of PV Systems Based on

Any of the variables in the objective function may be the variables of the optimization, and here, as an example, we select DC/AC ratio as the design parameter to optimize—that is the rated

Get Price

Understanding Solar Inverter Sizes: What Size Do

Did you know solar inverters come in different sizes? Learn why size is important and which size inverter you need for your solar PV system here.

Get Price

Optimal sizing of array and inverter for grid-connected photovoltaic

The rated capacity of a PV array must be matched with inverter''s rated capacity to achieve maximum PV output from a system (Decker et al., 1992). The optimal PV/inverter

Get Price

The optimal capacity ratio and power limit setting method of the

In order to maximize the power generation of the photovoltaic power generation system under the premise of ensuring the reliable operation of the system, a method for

Get Price

5 Factors Affect PV Module and Inverter Capacity Ratio

The PV module capacity and solar inverter capacity ratio are commonly referred to as capacity ratio. Reasonable capacity ratio design

Get Price

5 Factors Affect PV Module and Inverter Capacity Ratio

The PV module capacity and solar inverter capacity ratio are commonly referred to as capacity ratio. Reasonable capacity ratio design needs to be considered comprehensively

Get Price

Utility-Scale PV | Electricity | 2023 | ATB | NREL

PV system inverters, which convert DC energy/power to AC energy/power, have AC capacity ratings; therefore, the capacity of a PV system is rated in units of

Get Price

Solar plants typically install more panel capacity relative to their

For economic and engineering reasons, capacity values reported in DC typically are 10% to 30% higher than those reported in AC capacity. This ratio is often referred to as the

Get Price

The optimal capacity ratio and power limit setting method of the PV

In order to maximize the power generation of the photovoltaic power generation system under the premise of ensuring the reliable operation of the system, a method for

Get Price

Review on Optimization Techniques of PV/Inverter Ratio for

Abstract: In the literature, there are many different photovoltaic (PV) component sizing methodolo-gies, including the PV/inverter power sizing ratio, recommendations, and third-party field tests.

Get Price

DC/AC inverter oversizing ratio – what is the optimal ratio for

The ratio of the DC output power of a PV array to the total inverter AC output capacity. For example, a solar PV array of 13 MW combined STC output power connected to a 10 MW AC

Get Price

How does sizing a solar inverter work?

When it comes to solar inverter sizing, installers will consider three primary factors: the size of your solar array, geography, and site-specific conditions. The size of your solar

Get Price

OPTIMAL INVERTER SIZING RATIO FOR

Since the inverter rated power can be smaller, a specific term called "inverter sizing ratio" (ISR) is used to indicate the ratio of the DC power capacity of the PV array to the AC power capacity of

Get Price

How does sizing a solar inverter work?

When it comes to solar inverter sizing, installers will consider three primary factors: the size of your solar array, geography, and site-specific

Get Price

What DC to AC inverter load ratio is ideal for your application?

The DC to AC ratio (also known as the Inverter Load Ratio, or "ILR") is an important parameter when designing a solar project. For example, a 6-kW DC array combined with a 5

Get Price

Everything You Need to Know About Solar Inverter Sizing

A PV to inverter power ratio of 1.15 to 1.25 is considered optimal, while 1.2 is taken as the industry standard. This means to calculate the perfect inverter size, it is always better to choose an

Get Price

Solar Inverter Sizing Based on System Power Calculator

Calculate the perfect solar inverter size for your system power with our easy-to-use Solar Inverter Sizing Calculator. Optimize efficiency and performance.

Get Price

Solar Inverter Sizing Guide for Maximum Efficiency

Frequently Asked Questions (FAQ) What size solar inverter do I need? Your inverter should usually be 75% to 100% of your solar panel

Get Price

Improving PV plant performance via optimized inverter loading ratio

A team of scientists from the University College Cork in Ireland have proposed a new approach to designing inverter loading ratio (ILR) for utility-scale PV power plants. The

Get Price

Optimizing PV Plant DC-AC Ratios

As global demand for renewable energy surges, photovoltaic (PV) power plants have become pivotal to sustainable energy infrastructure. Among critical design parameters, the DC-AC

Get Price

The capacity ratio of photovoltaic power plants

The term ''capacity ratio'' is certainly unfamiliar to laypeople. Capacity ratio refers to the ratio of the nominal power of components in a photovoltaic power plant to the rated output

Get Price

037_ICE4CT2020

To investigate the PV array-inverter sizing ratio, many PV power plants rated power are considered. The proposed method is based on the modelling of several parts of the PV power

Get Price

Solar inverter sizing: Choose the right size inverter

DC/AC ratio refers to the output capacity of a PV system compared to the processing capacity of an inverter. It''s logical to assume a 9 kWh PV system should be paired with a 9 kWh inverter

Get Price

6 FAQs about [Photovoltaic inverter capacity ratio]

What is the array-to-inverter ratio of a solar panel system?

The array-to-inverter ratio of a solar panel system is the DC rating of your solar array divided by the maximum AC output of your inverter. For example, if your array is 6 kW with a 6000 W inverter, the array-to-inverter ratio is 1. If you install the same-sized array with a 5000 inverter, the ratio is 1.2.

What is PV module capacity & solar inverter capacity ratio?

The PV module capacity and solar inverter capacity ratio are commonly referred to as capacity ratio. Reasonable capacity ratio design needs to be considered comprehensively in the light of the specific project.

What ratio should a 5000 inverter have?

If you install the same-sized array with a 5000 inverter, the ratio is 1.2. Most installations will have a ratio between 1.15 to 1.25; inverter manufacturers and solar system designers typically do not recommend a ratio higher than 1.55. Below are some examples of solar inverter products and their maximum DC power output recommendation:

What size solar inverter do I Need?

Inverter size is measured in kilowatts (kW). It should match your solar array within a 1.15 to 1.33 ratio. Getting it wrong can reduce efficiency or disqualify you from solar rebates. What size inverter do I need for solar panels? To calculate, divide your solar panel system’s total DC rating by the desired inverter’s AC output.

Can a solar inverter be bigger than the DC rating?

The size of your solar inverter can be larger or smaller than the DC rating of your solar array, to a certain extent. The array-to-inverter ratio of a solar panel system is the DC rating of your solar array divided by the maximum AC output of your inverter. For example, if your array is 6 kW with a 6000 W inverter, the array-to-inverter ratio is 1.

How do I calculate a solar panel inverter ratio?

To calculate, divide your solar panel system’s total DC rating by the desired inverter’s AC output. This gives you the array-to-inverter ratio: For example: Within the ideal range (up to 1.33) set by many regulatory bodies, like Australia’s Clean Energy Council.

More related information

-

Photovoltaic inverter has large capacity

Photovoltaic inverter has large capacity

-

Can the inverter directly connect to the photovoltaic panel

Can the inverter directly connect to the photovoltaic panel

-

Myanmar photovoltaic inverter standards

Myanmar photovoltaic inverter standards

-

Photovoltaic water pump inverter cabinet

Photovoltaic water pump inverter cabinet

-

Burkina Faso Solar Photovoltaic Power Inverter

Burkina Faso Solar Photovoltaic Power Inverter

-

Nordic Photovoltaic Inverter

Nordic Photovoltaic Inverter

-

Proper installation of photovoltaic inverter

Proper installation of photovoltaic inverter

-

Photovoltaic three-phase inverter 30kw

Photovoltaic three-phase inverter 30kw

Commercial & Industrial Solar Storage Market Growth

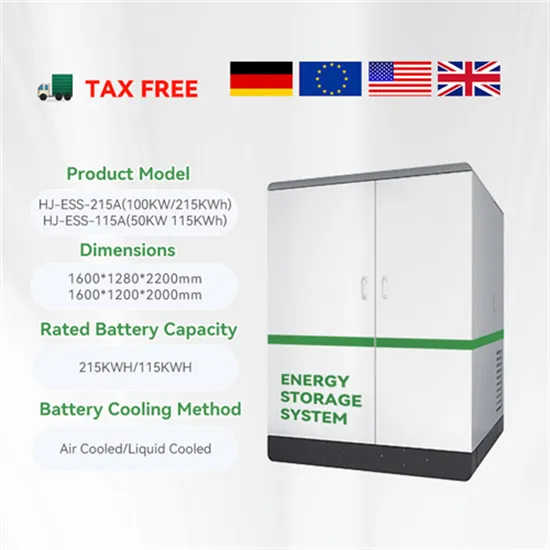

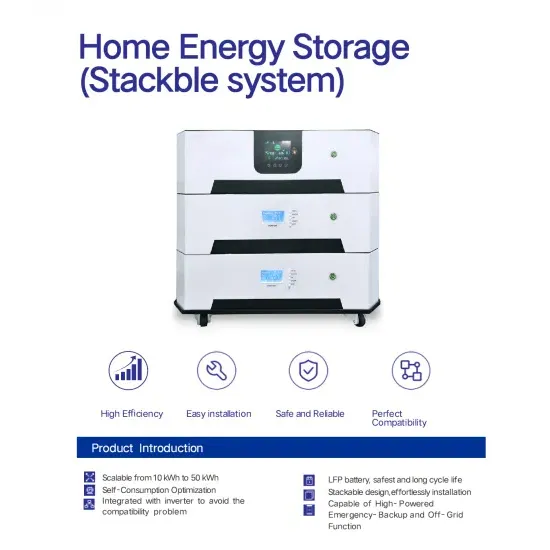

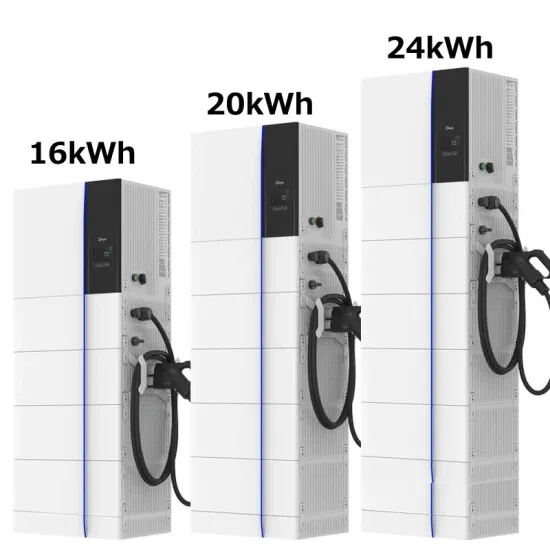

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.