Flywheel Energy Storage

Flywheel energy storage, an innovative mechanical energy storage method, will hold a significant position in the future energy storage field.

Get Price

Design Optimization of a Rotor for Flywheel Energy Storage

A literature review was carried out to study shapes used for rotor of flywheel energy storage system. The shapes commonly used in the recent literature are: cylindrical, conical, laval and

Get Price

Flywheel Energy Storage: A Comprehensive Guide

FES has a high power density and fast response time, making it suitable for applications that require rapid charging and discharging. However, its energy storage capacity

Get Price

Flywheel Energy Storage: A High-Efficiency Solution

Flywheel energy storage is an exciting solution for efficient and sustainable energy management. This innovative technology offers high efficiency and substantial environmental

Get Price

Energy storage flywheel retention system and method

An energy storage flywheel system includes a flywheel assembly that is rotationally mounted in a housing assembly, and one or more actuator assemblies. The actuator assemblies are

Get Price

Flywheel Energy Storage Discharge Time: What You Need to Know

That''s flywheel energy storage in a nutshell—minus the childhood nostalgia. This technology''s discharge time (how long it releases stored energy) is its make-or-break feature

Get Price

What is the self-discharge rate of flywheel energy storage?

A very low self-discharge rate, typically between 1% and 5% per hour, sets flywheels apart from traditional energy storage options. Integral to this performance are factors

Get Price

Flywheel discharge time Figure 10 presents the flywheel discharge time

Flywheel energy storage systems are considered as the grid integration of renewable energy sources due to their inherent advantages such as fast response, long cycle life and flexibility in

Get Price

Flywheel Energy Storage

For the first time, the flywheel energy storage compound frequency modulation project combines the advantages of "long life" of flywheel energy storage

Get Price

The Next Frontier in Energy Storage | Amber Kinetics, Inc

Leading Provider in Dispatchable Generation Amber Kinetics is a leading designer of flywheel technology focused the energy storage needs of the modern grid. By providing multiple cycles

Get Price

The Status and Future of Flywheel Energy Storage

Now, as other mechanical, thermal-to-electric, and renewable-fuel-based storage technologies develop, these will provide storage at a lower cost, greater duration, and in a

Get Price

Revterra

Advanced flywheel technology Revterra''s system stores energy through a spinning rotor, converting electric energy into kinetic energy and back when

Get Price

How much power does the flywheel store? | NenPower

Additionally, the integration of smart technologies into flywheel systems is gaining traction, enabling real-time monitoring and management of

Get Price

What is the cycle life of flywheel energy storage?

Flywheel systems demonstrate minimal degradation over time, allowing for sustained performance. One of the most critical aspects of

Get Price

A review of flywheel energy storage systems: state of the art and

A review of the recent development in flywheel energy storage technologies, both in academia and industry.

Get Price

What is the self-discharge rate of flywheel energy

A very low self-discharge rate, typically between 1% and 5% per hour, sets flywheels apart from traditional energy storage options. Integral to

Get Price

$200 Million For Renewables-Friendly Flywheel Energy Storage

1 day ago· The US startup Torus Energy combines flywheel technology with 21st century battery chemistry in one advanced energy storage system

Get Price

What are the flywheel energy storage software?

What are the flywheel energy storage software? Flywheel energy storage software encompasses a suite of applications designed to manage

Get Price

Flywheel Systems for Utility Scale Energy Storage

The kinetic energy storage system based on advanced flywheel technology from Amber Kinetics maintains full storage capacity throughout the product lifecycle, has no emissions, operates in

Get Price

A review of flywheel energy storage systems: state of the art

There is noticeable progress in FESS, especially in utility, large-scale deployment for the electrical grid, and renewable energy applications. This paper gives a review of the

Get Price

Flywheel energy storage

First-generation flywheel energy-storage systems use a large steel flywheel rotating on mechanical bearings. Newer systems use carbon-fiber composite rotors that have a higher

Get Price

Flywheel Energy Storage

Energy storage solutions are essential for integrating renewable energy sources like wind and solar by mitigating intermittency, enhancing grid

Get Price

What Is a Flywheel Energy Storage System?

At its core, a flywheel energy storage system stores energy in the form of rotational kinetic energy. The system consists of a large rotating mass, or rotor, that spins inside a

Get Price

(PDF) Energy Storage in Flywheels: An Overview

This paper presents an overview of the flywheel as a promising energy storage element. Electrical machines used with flywheels are surveyed

Get Price

What is the cycle life of flywheel energy storage? | NenPower

Flywheel systems demonstrate minimal degradation over time, allowing for sustained performance. One of the most critical aspects of flywheel energy storage is its ability

Get Price

A review of flywheel energy storage systems: state of the art and

There is noticeable progress in FESS, especially in utility, large-scale deployment for the electrical grid, and renewable energy applications. This paper gives a review of the

Get Price

6 FAQs about [Flywheel energy storage retention time]

What is a flywheel energy storage system?

First-generation flywheel energy-storage systems use a large steel flywheel rotating on mechanical bearings. Newer systems use carbon-fiber composite rotors that have a higher tensile strength than steel and can store much more energy for the same mass. To reduce friction, magnetic bearings are sometimes used instead of mechanical bearings.

Can flywheel energy storage be commercially viable?

This project explored flywheel energy storage R&D to reach commercial viability for utility scale energy storage. This required advancing the design, manufacturing capability, system cost, storage capacity, efficiency, reliability, safety, and system level operation of flywheel energy storage technology.

What is flywheel/kinetic energy storage system (fess)?

and high power quality such as fast response and voltage stability, the flywheel/kinetic energy storage system (FESS) is gaining attention recently. There is noticeable progress in FESS, especially in utility, large-scale deployment for the electrical grid, and renewable energy applications. This paper gives a review of the recent

How much energy does a flywheel store?

Indeed, the development of high strength, low-density carbon fiber composites (CFCs) in the 1970s generated renewed interest in flywheel energy storage. Based on design strengths typically used in commercial flywheels, σmax /ρ is around 600 kNm/kg for CFC, whereas for wrought flywheel steels, it is around 75 kNm/kg.

Can flywheels save energy?

Installing 100 MW’s worth of flywheels used for distribution can reduce demand charges by $36 million and provide $8 million of energy savings a year since the FESS can eliminate mid-day peak and evening peaks of electricity use. Lithium battery technology can only do one peak reduction a day.

Are flywheel-based hybrid energy storage systems based on compressed air energy storage?

While many papers compare different ESS technologies, only a few research [152,153] studies design and control flywheel-based hybrid energy storage systems. Recently, Zhang et al. present a hybrid energy storage system based on compressed air energy storage and FESS.

More related information

-

Cost per watt of flywheel energy storage

Cost per watt of flywheel energy storage

-

Signal Tower Flywheel Energy Storage

Signal Tower Flywheel Energy Storage

-

Dynamic flywheel energy storage

Dynamic flywheel energy storage

-

Application scenarios of flywheel energy storage

Application scenarios of flywheel energy storage

-

1KW flywheel energy storage system

1KW flywheel energy storage system

-

How many circuit breakers are there in flywheel energy storage

How many circuit breakers are there in flywheel energy storage

-

Which flywheel energy storage company is the largest

Which flywheel energy storage company is the largest

-

Flywheel Energy Storage Composite Frequency Modulation Project

Flywheel Energy Storage Composite Frequency Modulation Project

Commercial & Industrial Solar Storage Market Growth

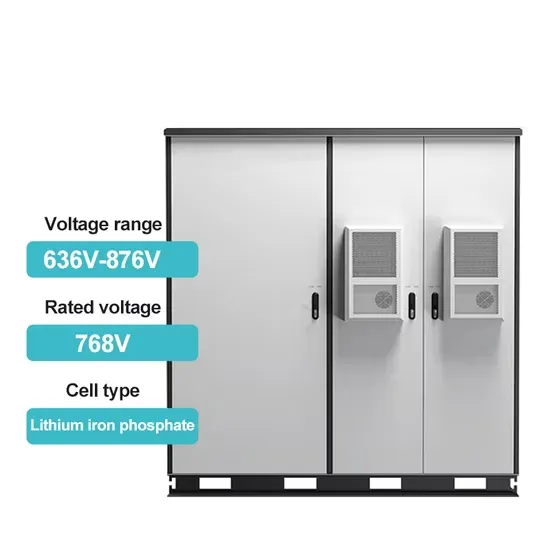

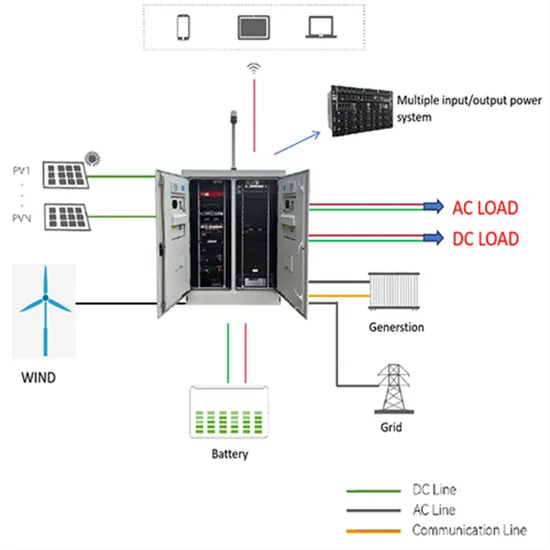

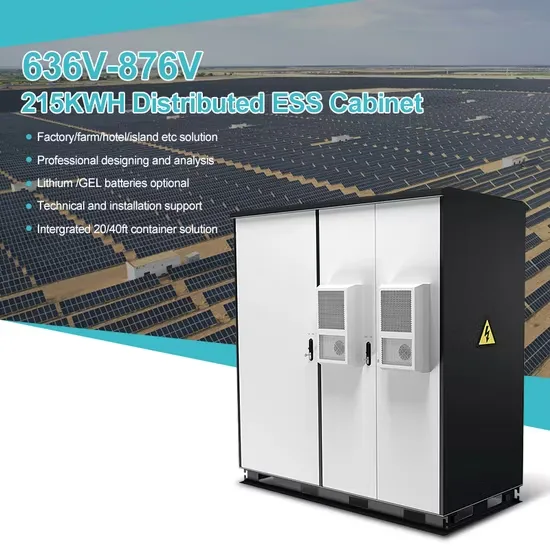

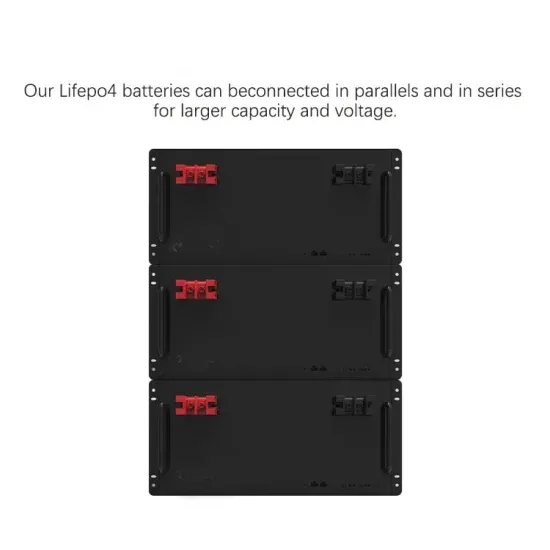

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.