Manual Preconditioning of the Battery to Improve

Battery preconditioning uses current through the drive motor coils to generate heat, then uses the liquid cooling/heating loop to pump heated

Get Price

Internal heating of lithium-ion batteries using alternating current

Both direct current and alternating current (AC) can generate heat inside the battery. When a direct current is used to heat the battery, both the amplitude and the duration of the

Get Price

How does the energy storage battery cabinet

These techniques involve mechanical systems specifically designed to reduce thermal loads within battery environments. Commonly

Get Price

An Intelligent Preheating Approach Based on High-Gain Control

However, it is difficult to preheat cold batteries rapidly without damaging them. Therfore, an intelligent preheating approach based on high-gain control is developed to

Get Price

How To Use Preheat Function On Vape

What is the preheat mode on a vape? The Preheat Mode is known to be similar to Temperature Control function, though the preheat will let you vape at lower wattage with just as good vapor

Get Price

Manual Preconditioning of the Battery to Improve Cold/Hot

Battery preconditioning uses current through the drive motor coils to generate heat, then uses the liquid cooling/heating loop to pump heated fluid through the battery packs.

Get Price

What Does The Preheat Do On A Vape

What is the preheat mode on a vape? The Preheat Mode is known to be similar to Temperature Control function, though the preheat will let you vape at lower wattage with just as good vapor

Get Price

Battery cabinet preheating technology

The battery pack could be heated from -20.84°C to 10°C in 12.4 min, with an average temperature rise of 2.47 °C/min. AC heating technology can achieve efficient and

Get Price

What Is the Battery Capacity of Samsung Galaxy S9

Firmware Updates: Samsung''s post-launch updates often included battery calibration improvements, highlighting the importance of keeping software current. For power

Get Price

Battery heating strategy to enhance fast-charge performance at

A critical issue at low temperatures is prolonged charging time, even with fast charging. This delay occurs because the battery management system (BMS) actively

Get Price

Introduction to Battery Preheating Technology

The G3 utilizes an integrated HVAC controller that provides more sensitive temperature control for the battery. As shown in the diagram, the

Get Price

Battery Cabinet

CAUTION: Risk of Energy Hazard, 0 – 700 Vdc (Volts Direct Current), 0 – 400 Ampere-hour battery or higher. Before replacing batteries, remove conductive jewelry such as chains, wrist

Get Price

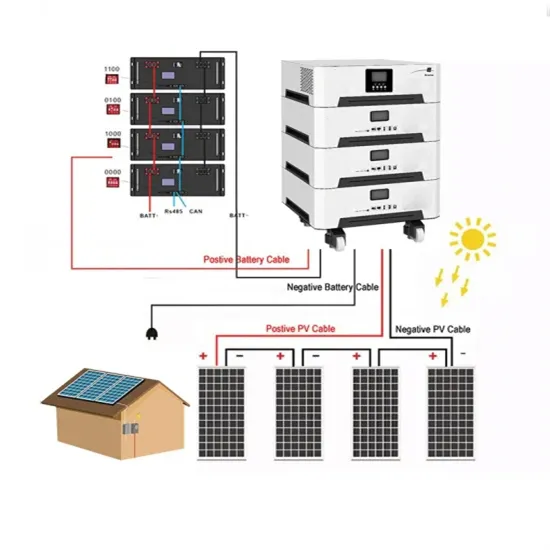

A Guide to Understanding Battery Storage Specifications

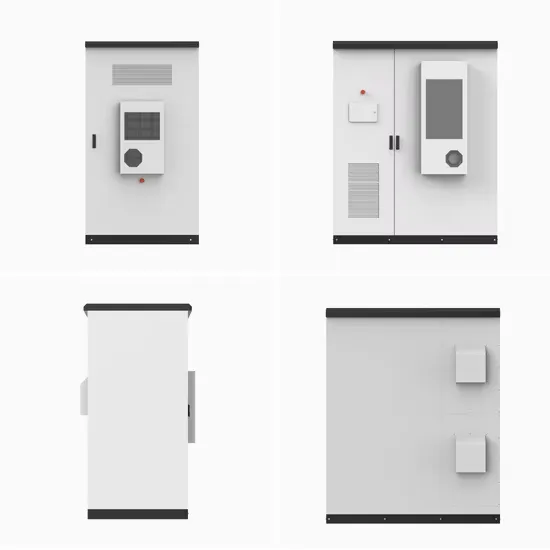

Battery Cabinet: A battery cabinet serves as a protective and organized enclosure for housing multiple battery modules within an energy storage system. Its

Get Price

Supercharging A Tesla In Winter: Preconditioned Vs.

Battery preconditioning—or simply put, battery preheating—is critical before a DC fast charging session, especially in the cold season that we now have in the

Get Price

How does the energy storage battery cabinet dissipate heat?

These techniques involve mechanical systems specifically designed to reduce thermal loads within battery environments. Commonly employed methods include refrigeration

Get Price

UPS WITH A BATTERY SYSTEM 101. EDUCATION FOR

Typically a UPS with a battery system is specified at 100 % load of the UPS with a 15 minute VRLA battery runtime. If an end user decides on VLA or a NiCad battery system, a telephone

Get Price

To charge a battery, a Cables with connectors are provided on the associated power system and the battery cabinet to allow simple interconnections between a battery cabinet and the

Get Price

(PDF) Review on preheating systems for Lithium-ion batteries of

Therfore, an intelligent preheating approach based on high-gain control (HGC) is developed to adaptively adjust the AC heating current based on heating rate and battery

Get Price

Introduction to Battery Preheating Technology

The G3 utilizes an integrated HVAC controller that provides more sensitive temperature control for the battery. As shown in the diagram, the battery pack heating function

Get Price

UBC87 Battery Cabinet Installation, Operation,

Whether the Battery Cabinet is empty or partially assembled, it should be located, mounted and properly grounded prior to final assembly as instructed in this manual in sections 6.2.1, 6.2.2

Get Price

What is the normal preheating current of the battery cabinet

The RMS value of the heating current of the 2S battery pack is about 6.3 A when the input voltage is 10 V, and the RMS values for 4S and 6S battery packs are 3.8 A and 2.0 A, respectively, but

Get Price

Is preheat killing my range or is this normal?

By preheating the battery to a modest temperature - my car seems to target 15C - you get normal performance immediately since the current capability is then normal and better

Get Price

Thermal runaway behaviour and heat generation optimization of

Based on the thermal runaway (TR) module, a three-layer marine battery cabinet was visually analysed for the first time, and the influence of TR on the upper and lower layers

Get Price

How to calculate preheat temperature for welding?

This preheat calculator assists welders in determining the appropriate preheat temperature for their welding projects. Preheating is an

Get Price

Pre-condition Battery : r/BMWI4

The car does it automatically if you navigate to a charger. The difference is HUGE. Without preheating, in winter, when cold (20 min drive to charger), I

Get Price

Q&A: What is the principle of preheating the electric car battery?

Q: What is the principle of preheating the electric car battery? A: In the winter, the battery life of electric vehicles will generally shrink greatly, mainly because of the low temperature, the

Get Price

Tesla How to Preheat Battery? For Maximum Range

The preheating time for a Tesla battery varies depending on factors such as the ambient temperature, the desired temperature, and the battery''s current state of charge.

Get Price

6 FAQs about [What is the normal preheating current of the battery cabinet ]

Does alternating current generate heat inside a battery?

Both direct current and alternating current (AC) can generate heat inside the battery. When a direct current is used to heat the battery, both the amplitude and the duration of the current should be restricted to very low values to avoid lithium deposition, thereby limiting the heat generation rate and the preheating effectiveness.

Can a battery be heated externally or internally?

The batteries can be heated either externally or internally . External heating always adopts electrical heating actuators. These actuators are embedded in a blanket wrapped outside the battery pack, or immersed in the flow channels using liquid or air as the medium to heat the battery , .

Can a sinusoidal alternating current preheat lithium-ion batteries at low temperature?

In this study, a method was developed to internally preheat lithium-ion batteries at low temperature using a sinusoidal alternating current. A model in the frequency domain was developed to simulate the heat generation rate based on the EEC.

What is the maximum battery voltage during AC heating process?

In this study, during the AC heating process, a maximum battery voltage around 4.5 V was recorded because of the high current amplitude of ∼2 C. This cell voltage should be high enough to cause lithium deposition from the normal consideration of deposition potential.

Does AC heating a battery cause lithium deposition?

When AC heating the battery, both the amplitude and the frequency of the current affect the possibility of the occurrence of lithium deposition. In this study, during the AC heating process, a maximum battery voltage around 4.5 V was recorded because of the high current amplitude of ∼2 C.

What is the temperature distribution of a test battery?

The test battery subjected to an alternating current with an amplitude of 7 A (2.25 C) and a frequency of 1 Hz under an equivalent heat transfer coefficient of 15.9 W m −2 K −1 can be heated from −20 °C to 5 °C in less than 15 min and the temperature distribution remains essentially uniform.

More related information

-

What is the current of the 12v battery in the energy storage cabinet

What is the current of the 12v battery in the energy storage cabinet

-

What to do if the battery cabinet current exceeds the limit

What to do if the battery cabinet current exceeds the limit

-

What is the approximate current of the energy storage cabinet battery

What is the approximate current of the energy storage cabinet battery

-

What is the current cost of lithium battery energy storage

What is the current cost of lithium battery energy storage

-

What are the battery cabinet manufacturers

What are the battery cabinet manufacturers

-

What are the uses of energy storage cabinet battery technology

What are the uses of energy storage cabinet battery technology

-

How to increase the current of the battery cabinet

How to increase the current of the battery cabinet

-

Current distribution inside the battery cabinet

Current distribution inside the battery cabinet

Commercial & Industrial Solar Storage Market Growth

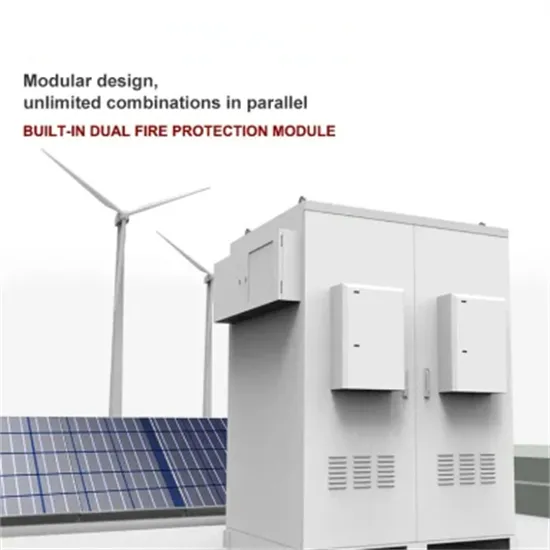

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.