Considerations for Choosing a Vibration Table | Deca

Industrial vibration tables are valuable instruments for diverse applications, including quality control, material separation, condensing and

Get Price

Laboratory > Cycler > Accessories > Vibrating table

With the vibrating table from Digatron, you can simulate vibration testing according to EN 50342 with a frequency of up to 60 Hz and up to 6 g

Get Price

Battery Vibration Testing

Battery Vibration Testing Vibration control is a necessary part of the reliability testing of batteries, ranging from small cells to automotive lithium-ion packs.

Get Price

Vibration Tables Customized Lithium Ion Battery New Energy

We stick to the principle of "quality first, service first, continuous improvement and innovation to meet the customers" for the management and "zero defect, zero complaints" as the quality

Get Price

Laboratory > Cycler > Accessories > Vibrating table

With the vibrating table from Digatron, you can simulate vibration testing according to EN 50342 with a frequency of up to 60 Hz and up to 6 g acceleration on starter batteries. The vibrating

Get Price

Battery Cabinet Vibration Testing | HuiJue Group E-Site

Meanwhile, the new ISO 21782-2024 standard mandates vibration spectrum mapping across six environmental variables simultaneously. Consider this: When our team retrofitted a

Get Price

Design and Optimization for a New Locomotive Power

(4) The power battery adopts a two-stage protection design under the battery power level, which can simultaneously achieve battery protection

Get Price

New energy battery high frequency electromagnetic

The electromagnetic vibration test bench is mainly used for product vibration environment and impact environment test, environmental stress screening test

Get Price

Large EV Battery Vibration Testing | MTS Systems

The Model 354 LG (Large-Geometry) Multi-Axial Simulation Table is purpose-engineered to support a full spectrum of vibration testing of lithium-ion battery packs used in electric

Get Price

EV Battery Testing

Electric MAST table (Multi-Axial Simulation Table) for 6 degrees of freedom vibration testing - delivering faster response, higher frequency and enhanced eficiency

Get Price

ESTEL Outdoor Battery Cabinet Buying Guide for 2025

Find tips to choose the best outdoor battery cabinet for your energy needs, focusing on size, cooling, durability, and future expansion options.

Get Price

The Ultimate Guide to Vibration Testing for EV Battery Packs

Power battery systems are usually fixed to the vibration table using specially designed fixtures. The main function of the fixtures is to secure the sample to the table and

Get Price

公司简介

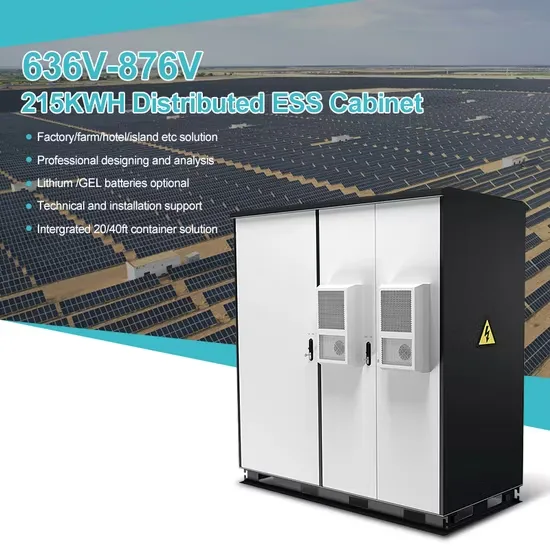

I. Scope of Application This specification is suitable for the 100kW/215kWh industrial and commercial energy storage system developed by Anhui Lvwo Recycling Energy Technology

Get Price

Jtam-A4.dvi

For new energy vehicles, the key component that affects vehicle safety is the battery pack. As the carrier of the battery, the importance of the battery pack cannot be underestimated. The

Get Price

Battery Cabinets for Uninterrupted Power Supply (UPS)

Battery Cabinets Through cutting-edge research and innovation, advanced engineered power products for backup battery cabinets have become

Get Price

High Voltage Battery Cabinet: Efficient Energy Storage

The Core of Modern Energy Management In the global shift towards sustainability, the role of efficient power management has become more critical than ever. At the heart of this

Get Price

Battery vibration test – an important part of battery

Battery vibration test is to evaluate the ability of power battery around safety indicators. Among them, the safety indicators of the vibration

Get Price

NEW YORK CITY FIRE DEPARTMENT

The movement to replace fossil fuels with alternative energy sources to address global environmental concerns has prompted the rapid development of new energy storage

Get Price

Vibration Tables Customized Lithium Ion Battery New

We stick to the principle of "quality first, service first, continuous improvement and innovation to meet the customers" for the management and "zero defect, zero

Get Price

Analysis and Experimental Tests of Potential New Mounting

The article discusses the basic requirements for the fixture of specimens subjected to vibration testing and fastening it to a slip table of head expander, giving a better

Get Price

Vibration Control and Anti-Vibration Tables

With over 50 years of vibration control and vibration isolation design and manufacturing experience, Newport has become the industry standard for optical tables, isolation systems,

Get Price

Battery vibration test – an important part of battery quality assurance

Battery vibration test is to evaluate the ability of power battery around safety indicators. Among them, the safety indicators of the vibration test include: sufficient insulation,

Get Price

How about new energy storage cabinet | NenPower

How about new energy storage cabinet: 1. Innovative technology, 2. Enhanced efficiency, 3. Environmental sustainability, 4. Versatile applications.

Get Price

New energy battery high frequency electromagnetic vibration test

The electromagnetic vibration test bench is mainly used for product vibration environment and impact environment test, environmental stress screening test and reliability test.

Get Price

New Energy Battery Vibration Test System With Large Vertical Table

As batteries are increasingly being used in various applications, including electric vehicles and renewable energy storage systems, it is essential to evaluate their performance under

Get Price

Analysis and Experimental Tests of Potential New

The article discusses the basic requirements for the fixture of specimens subjected to vibration testing and fastening it to a slip table of head

Get Price

New Energy Battery Vibration Test System With Large

As batteries are increasingly being used in various applications, including electric vehicles and renewable energy storage systems, it is essential to evaluate

Get Price

Vibration Tables | Vibration Testing | Boxes, Molds, Drums

Learn more vibration tables used for testing, compaction, settling, and shaking products in molds, boxes, packaging, bags, drums, and more.

Get Price

Large EV Battery Vibration Testing | MTS Systems

The Model 354 LG (Large-Geometry) Multi-Axial Simulation Table is purpose-engineered to conduct a full spectrum of vibration testing of lithium-ion battery

Get Price

6 FAQs about [New Energy Battery Cabinet Vibration Table]

How a power battery system is fixed to a vibration table?

Power battery systems are usually fixed to the vibration table using specially designed fixtures. The main function of the fixtures is to secure the sample to the table and transmit the vibration load from the table to the test sample without distortion.

What type of vibration table is used for vibration testing?

Vibration testing is generally conducted using a vibration table, which can be mechanical, hydraulic, or electric. Electric vibration tables are the most widely used, with a broad working frequency range, good vibration waveform, and easy control and operation, generally meeting the requirements for vibration tests above 2Hz.

What are the standards for vibration testing of battery systems?

Most testing standards for battery systems include vibration tests. The national mandatory standard GB38031 ⇱, issued in 2020, clearly defines the methods and requirements for vibration testing of power battery systems. The relevant standards for vibration testing of battery systems in both domestic and international contexts are as follows:

What is vibration testing of power battery systems?

Vibration testing is an essential method for assessing the mechanical reliability of power battery systems. This article primarily introducing the vibration testing methods of power battery systems. 1. Vibration Testing 2. Comparison of Battery System Vibration Standards 3. Vibration Testing of Power Battery Systems 1. Vibration Testing

What is a vibration test for lithium batteries?

UN 38.3 is primarily used to simulate the vibration loads experienced by lithium batteries during transportation. The vibration test in this standard is conducted with sweep-frequency vibrations in the X, Y, and Z directions, and the vibration test level varies depending on the weight of the sample (12kg).

Why is vibration test important for electric vehicle power batteries?

Electric vehicle power batteries are generally arranged in the lower body of the vehicle. The electric vehicle power battery is subjected to the vibration excitation transmitted by the road surface during the complete life cycle of the vehicle. Therefore, the vibration test is an important link in the design and development of the battery pack.

More related information

-

New Energy Battery Cabinet Vibration Table

New Energy Battery Cabinet Vibration Table

-

Barbados New Energy Battery Cabinet

Barbados New Energy Battery Cabinet

-

New Energy Battery Cabinet Product Model

New Energy Battery Cabinet Product Model

-

Zhixiang Technology New Energy Battery Cabinet

Zhixiang Technology New Energy Battery Cabinet

-

Replace new energy battery cabinet

Replace new energy battery cabinet

-

Parameters of new energy battery cabinet

Parameters of new energy battery cabinet

-

What is the total voltage of the new energy battery cabinet

What is the total voltage of the new energy battery cabinet

-

Asia New Energy Battery Cabinet 372KWh

Asia New Energy Battery Cabinet 372KWh

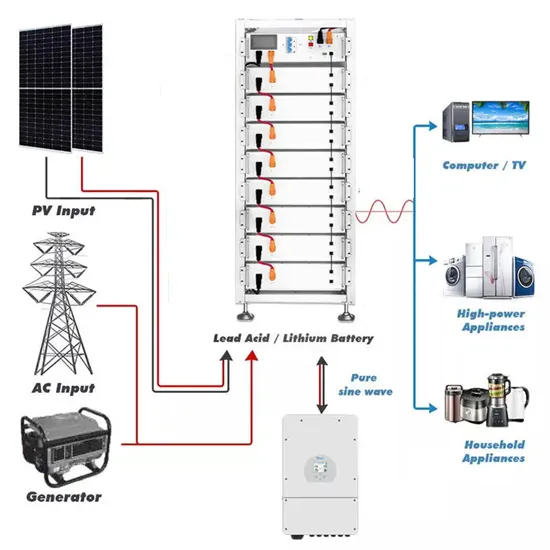

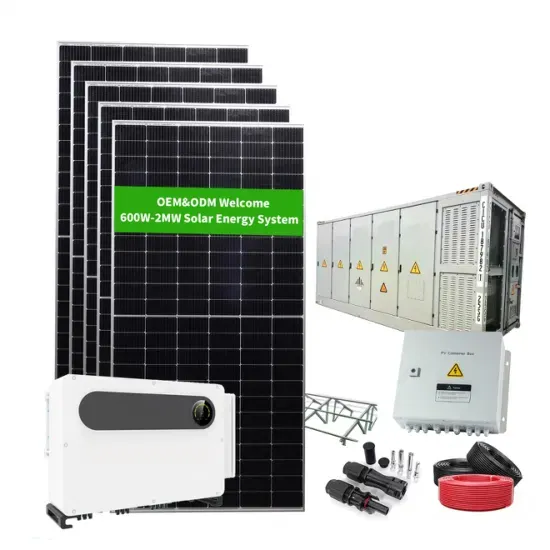

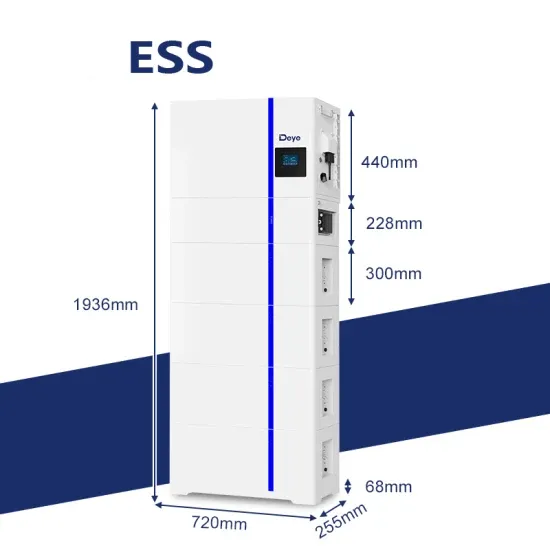

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.