Solar Photovoltaic System Cost Benchmarks

The U.S. Department of Energy''s solar office and its national laboratory partners analyze cost data for U.S. solar photovoltaic systems to develop cost

Get Price

How much is the factory price of solar energy | NenPower

The factory price of solar energy can vary significantly, influenced by several factors such as the type of solar technology used, regional market conditions, and the scale of

Get Price

The State of the Solar Industry

State-by-State Electricity from Solar (2023) Sources: U.S. Energy Information Administration, "Electric Power Monthly," forms EIA-023, EIA-826, and EIA-861. U.S. Energy Information

Get Price

Commercial Solar Systems | Solar System Cost

Commercial solar systems by Solar Electric Supply (SES) are custom solar panel grid-tie power systems for commercial buildings using REC, SolarWorld,

Get Price

Testing of Photovoltaic Module

Electroluminescence Test – Test per sample of PV module Testing of photovoltaic Solar Cells: Solar cell testing facility at NISE is capable of testing solar cells. The setup is capable of

Get Price

How much is the factory price of solar energy

The factory price of solar energy can vary significantly, influenced by several factors such as the type of solar technology used, regional market

Get Price

Photovoltaic Module Prices 2025: Updated Data

Prices for photovoltaic modules in 2024 continue to fall. According to the monthly index published by Germany''s pvXchange Trading, the

Get Price

Vikram Solar | Solar Plate Manufacturing & Solar Panels Company

Vikram Solar is a leading solar plate manufacturing company and among the top roof top solar companies in India, trusted as one of the best solar install companies.

Get Price

Solar Photovoltaic System Cost Benchmarks

The U.S. Department of Energy''s solar office and its national laboratory partners analyze cost data for U.S. solar photovoltaic systems to develop cost benchmarks to measure progress

Get Price

Cost Breakdown of a Solar Panel: From

It offers valuable insights into the factors that shape the pricing strategies in the solar energy sector. The solar energy industry has witnessed

Get Price

Photovoltaic (PV) Module Technologies: 2020 Benchmark

Photovoltaic (PV) module prices are a key metric for PV project development and growth of the PV industry. The general trend of global PV module pricing has been a rapid and steep

Get Price

How Much Does It Cost to Start a Solar Panel Manufacturing Plant?

Starting a solar panel manufacturing plant can involve costs ranging from $500,000 to several million dollars, depending on factors like facility size and technology used.

Get Price

Suntech

Suntech, founded in 2001, as a famous photovoltaic manufacturer in the world, is devoted to the R & D and the production of crystalline silicon solar cells and

Get Price

Solar Panel Manufacturing Cost: A Complete Factory

Do you want to start a solar panel manufacturing factory and you need an in-depth solar panel manufacturing plant cost breakdown? If yes, then

Get Price

Solar (photovoltaic) panel prices

IRENA presents solar photovoltaic module prices for a number of different technologies. Here we use the average yearly price for technologies

Get Price

Ultimate Guide to Buying Solar Panels from China – 2024

In this article, ADNLITE shares valuable insights on several key aspects how to buy solar panel from Chinese Manufacturers.

Get Price

Wholesale Solar Panels

About Wholesale Solar Panels If you are looking for a place to buy wholesale solar panels, you''ve found it. A1 SolarStore offers PV modules from

Get Price

Solar Manufacturing Cost Analysis | Solar Market

NREL analyzes manufacturing costs associated with photovoltaic (PV) cell and module technologies and solar-coupled energy storage

Get Price

Industrial Solar Panel Price in India 2025 | Complete Cost Guide

Explore the latest 2025 guide on industrial solar panel prices in India. Discover installation costs, system types, pricing breakdown

Get Price

How Much Does It Cost to Start a Solar Panel

Solar Panel Manufacturing Plant Costs are a critical consideration for anyone looking to start a solar panel manufacturing plant. This article breaks down the

Get Price

How Much Do Industrial Solar Panels Cost?

By determining the cost of solar power, businesses can evaluate the potential subsidies and tax incentives they may receive. Typically, before tax subsidies and rebates, the cost of

Get Price

Innovators of Solar Components | Commitment to

Frames that capture the sun Aluminum Solar Panel Frame Vishakha designs and manufactures aluminum frame solar panel which provides structural support to

Get Price

Cost Breakdown of a Solar Panel: From Manufacturing to Market

It offers valuable insights into the factors that shape the pricing strategies in the solar energy sector. The solar energy industry has witnessed a remarkable evolution over the

Get Price

Solar Manufacturing Cost Analysis | Solar Market Research & Analysis | NREL

NREL analyzes manufacturing costs associated with photovoltaic (PV) cell and module technologies and solar-coupled energy storage technologies.

Get Price

How Much Do Industrial Solar Panels Cost?

By determining the cost of solar power, businesses can evaluate the potential subsidies and tax incentives they may receive. Typically, before tax subsidies

Get Price

How Much Does It Cost to Start a Solar Panel

Starting a solar panel manufacturing plant can involve costs ranging from $500,000 to several million dollars, depending on factors like facility size and

Get Price

Solar PV Module Manufacturing Cost Analysis | Case Study

The model predicts profitability while accounting for market trends, inflation, and any shifts in the price of raw materials. It was created especially to satisfy the demand of producing 1,000 MW

Get Price

Solar (photovoltaic) panel prices

IRENA presents solar photovoltaic module prices for a number of different technologies. Here we use the average yearly price for technologies ''Thin film a-Si/u-Si or

Get Price

6 FAQs about [Factory photovoltaic module price standard]

How much does a photovoltaic module cost?

Mainstream Modules: Average price of €0.11/Wp, stable compared to September but 21.4% lower than January 2024. Low-Cost Modules: Average price of €0.065/Wp, a 7.1% decrease from September and 27.8% from January 2024. These trends are exerting mounting pressure on the photovoltaic sector.

What are polycrystalline solar photovoltaic (PV) modules?

Polycrystalline solar photovoltaic (PV) modules are a key component of solar energy systems, harnessing sunlight and converting it into electricity through the photovoltaic effect. These modules are composed of multiple interconnected solar cells, each made from polycrystalline silicon.

What are the raw materials required for solar PV module manufacturing?

Raw Material Required: The primary raw materials utilized in the solar PV module manufacturing plant include solar cells, tempered glass, aluminium frame, encapsulant (EVA), and wiring and junction box. Techno-Commercial Parameter:

How much does a photovoltaic panel cost?

Mainstream Photovoltaic Panels: Average price of €0.10/Wp, down 9.1% month-on-month. Low-Cost Photovoltaic Modules: Average price of €0.060/Wp, a decrease of 7.7% compared to the previous month. These figures underscore the significant pressures in the photovoltaic market, as price reductions strain margins to unprecedented levels.

What is PV system cost model (pvscm)?

The total cost over the service life of the system is amortized to give a levelized cost per year. In the PV System Cost Model (PVSCM), the owner’s overnight capital expense (cash cost) for an installed PV system is divided into eight categories, which are the same for the utility-scale, commercial, and residential PV market segments:

How are PV production costs modeled?

The costs of materials, equipment, facilities, energy, and labor associated with each step in the production process are individually modeled. Input data for this analysis method are collected through primary interviews with PV manufacturers and material and equipment suppliers.

More related information

-

Timor-Leste new photovoltaic module selling price

Timor-Leste new photovoltaic module selling price

-

Somaliland Photovoltaic Module Factory Project

Somaliland Photovoltaic Module Factory Project

-

Single glass photovoltaic module price

Single glass photovoltaic module price

-

Photovoltaic panels solar factory wholesale price

Photovoltaic panels solar factory wholesale price

-

New flexible photovoltaic module price

New flexible photovoltaic module price

-

Module 660 photovoltaic panel price

Module 660 photovoltaic panel price

-

Price of 1GW photovoltaic module

Price of 1GW photovoltaic module

-

Thin-film photovoltaic module 1kw price

Thin-film photovoltaic module 1kw price

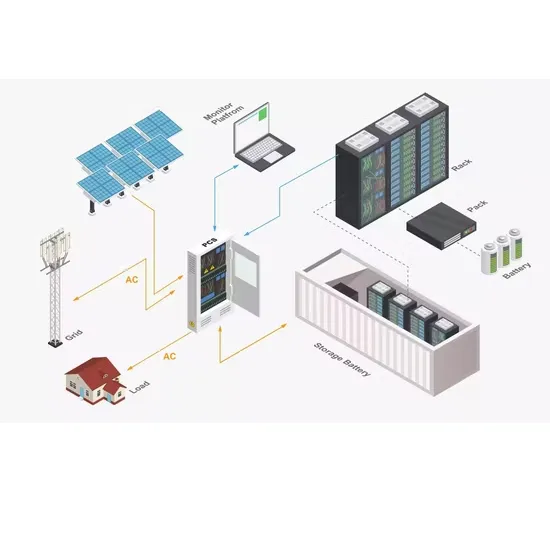

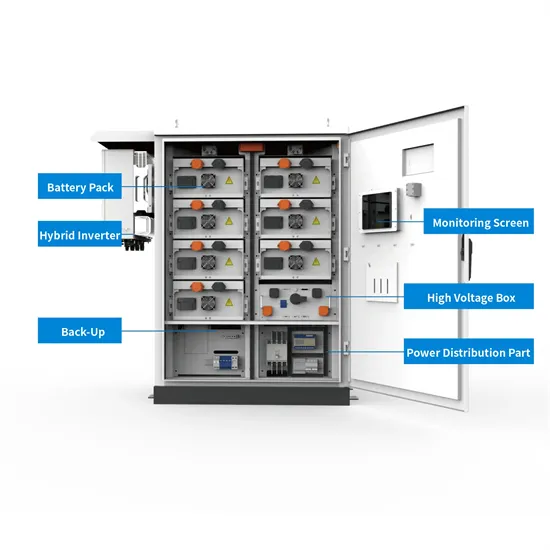

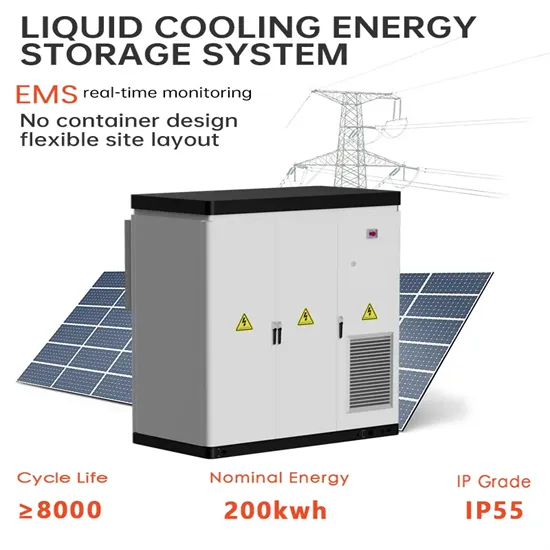

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

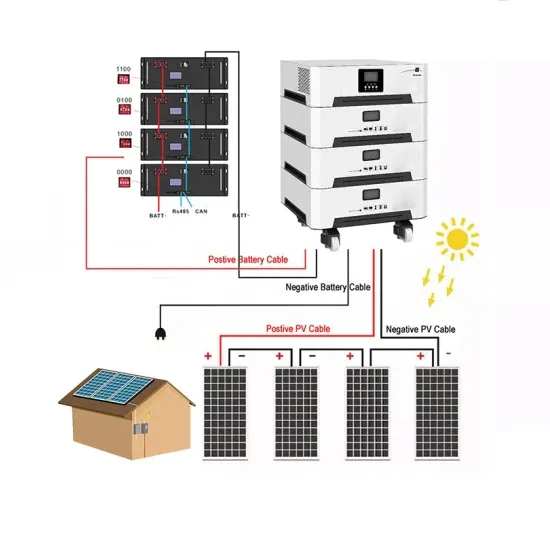

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.